SICK Automation sHub sensors enable comprehensive machine monitoring

An automation solution to enable a packaging process plant to carry out condition monitoring and predictive maintenance more efficiently has led to reduced operating costs and increased productivity.

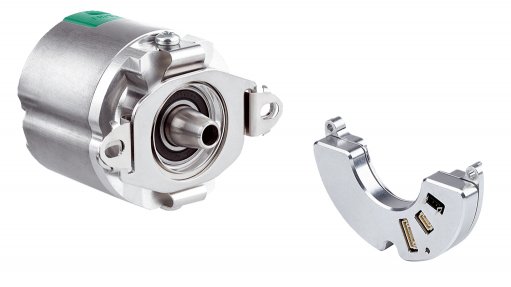

Sensor specialist SICK collaborated with packaging company Tetra Pak, when it sought a solution that would prevent unscheduled downtime in its packaging plants. To address Tetra Pak’s requirements, SICK recommended the utilisation of its sHub sensors with EDS/EDM35 feedback system. The motor feedback system incorporates an acceleration sensor and enables comprehensive condition monitoring of electrical drives on a machine. It monitors position and speed as well as measuring vibrations. Equipped with HIPERFACE DSL infrastructure, the sHub sensors are designed to be easily integrated.

The sensors enable a self-optimised process that detects acute issues, allowing for early intervention and preventative maintenance. This increases the reliability of drive systems in a packaging processing plant for effective and efficient function, through its connected devices and machines. For instance, SICK can predict ball bearing failure, a critical component in a servomotor that is seen as the leading cause of motor failure.

The sHub encompasses an integrated acceleration sensor in combination with a displacement sensor. The solution can be implemented within a servomotor housing, without additional space requirements. Data is transferred over HIPERFACE DSL to the Servo Drive, which prepares and processes the process data according to the customer requirements by means of fieldbus and passes it on to the higher-level controller for analysis. The sHub is said to be easy-to-install and the sensors and electronics are also protected against moisture.