AZ Hollink

AZ Hollink South Africa is the sole representative for RENK Hanover in South Africa and authorised dealer for all RENK products in sub-Saharan Africa.

Established in September 2010, AZ Hollink South Africa is a sister company of the AZ Hollink Group, an exclusive international specialist in mechanical transmission components. Located at The Colosseum in Century City, Cape Town, AZ Hollink South Africa occupies a site area of 200 m2, with 100 m2 under cover, and employs six staff members.

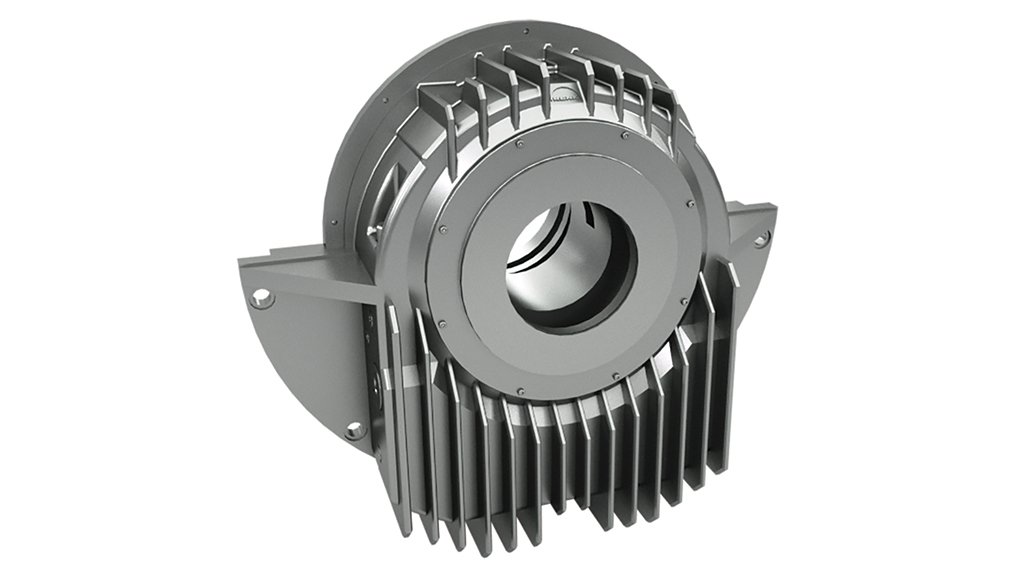

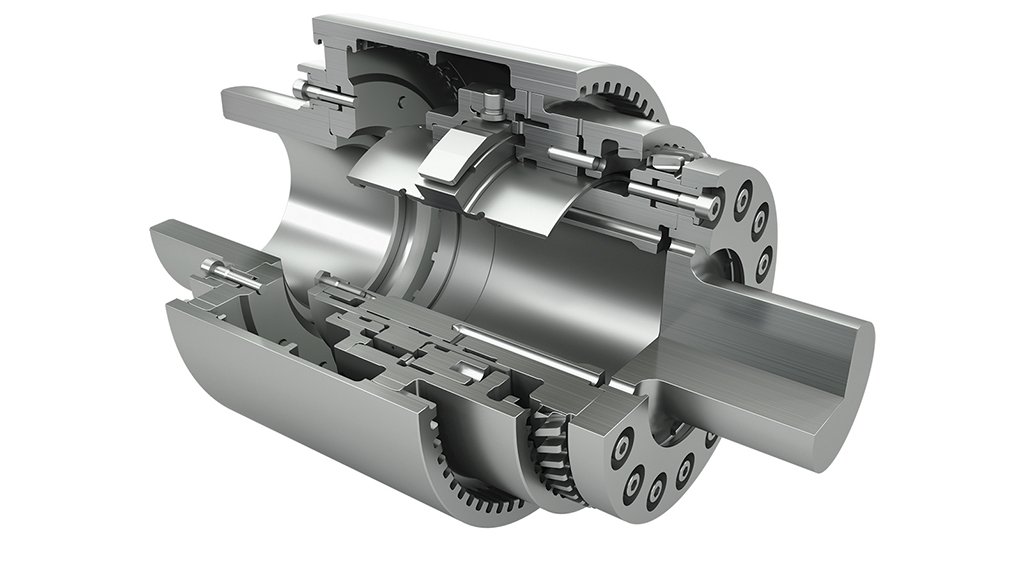

AZ Hollink South Africa offers the largest variety of industrial transmission products, with its product range focused on RENK original-equipment (OEM) products, including bearings, couplings, gearboxes and all related spares. RENK Hannover is the global market leader in slide bearings, couplings and gear boxes, with a focus on the high-end market.

AZ Hollink South Africa has extensive knowledge of a range of market sectors such as the industrial, agricultural, mining, printing, shipbuilding and the power generation industry. AZ Hollink South Africa distributes OEM products throughout South Africa and the sub-Sahara region and prides itself on providing high quality products and excellent service that is customer focussed with a personal approach.

Slide bearings are one of the most crucial components of any machinery and for a precision part such as a RENK slide bearing, it is essential to use only original parts. Bearings can be overhauled only once and should always be undertaken by the RENK Hannover factory, as tolerances are small and need to be extremely accurate. In most cases, however, only a new bearing or parts will lead to a long-term solution. Failing to use expertly revised or new RENK parts will have a negative effect on the lifetime, efficiency and reliability of a drive train. As AZ Hollink points out: similar is not the same!

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation