The remarkable properties of plasma coating technologies from coating specialists, Thermaspray, can extend component service life and reduce costs significantly. This is achieved by improving component performance and efficiency in the adhesives and labelling industry.

Replacing parts with new OEM parts or repairing components with alternative (and often inferior) types of coatings, like polymers that do not have a thermally sprayed matrix (base) coating, can prove to be very costly. By comparison, the application of plasma coatings to components used in the adhesives and labelling industry such as aluminium rolls, glue applicator wheels, glue pans, glue tanks, rotary die cutters, scrapers, waste matrix take off rolls and waste removal ducting offers a highly effective and more affordable alternative with significant time and cost saving benefits for end users.

The plasma polymer spray system is a dual coating technique that combines the advantages of thermally sprayed coatings with polymer based top-coatings to offer the benefits of wear resistance, non-slip and traction characteristics. Plasma coatings consist of a base (matrix) coating which is applied through a thermal spray process, followed by the application of a final layer of polymer coating.

Thermal spraying is the method of depositing a metallic, or non-metallic, powder onto the surface of a component, by feeding the powder into a heat source, and thereafter into a high velocity gas stream. Molten particles are then propelled by the high velocity gas onto a prepared substrate surface, where a mechanical bond occurs between the substrate and the coating. This base coating is applied by one of four different types of techniques; Combustion Wire Metallizing, Electric Arc, Plasma or High Velocity Oxygen Fuel (HVOF).

Plasma coating technology was not available to local industry until 2014, when Thermaspray, in partnership with Plasma Coatings USA, a Division of American Roller Company, became the first company in South Africa to introduce plasma coatings. “It is the first time that the combination of thermal sprayed coatings and polymer coatings has been available within one company,” states Thermaspray Managing Director, Dr Jan Lourens.

As a formal licensee for Plasma Coatings, Thermaspray has made a substantial investment in bringing the technology to South Africa. In addition to acquiring new equipment such as polymer spraying systems and curing ovens, the company converted a traditional spray booth to meet all the necessary needs and application standards for plasma coatings.

The coating properties of plasma coatings include release (non-stick), corrosion- and wear resistance, traction and release and low friction. These coatings deliver a number of important benefits (depending on the application);

• Improved surface integrity;

• Improved component efficiency;

• Enhanced quality of the surface interface;

• Noise reduction;

• Elimination of generated static electricity;

• Lower Coefficient of Friction (COF); and

• Combined wear / chemical resistance.

The properties of plasma coatings make this technology ideally suited to the food processing, plastics and paper, tyre and rubber, packaging, printing and pulp industries.

Since Thermaspray introduced plasma coatings to the local market, the technology has been widely accepted across a range of sectors. Dr Lourens attributes this to the many cost and time saving benefits offered by this world-class technology. Two recent examples where Thermaspray has successfully assisted customers in the adhesives and labelling industry by extending component-life include are:

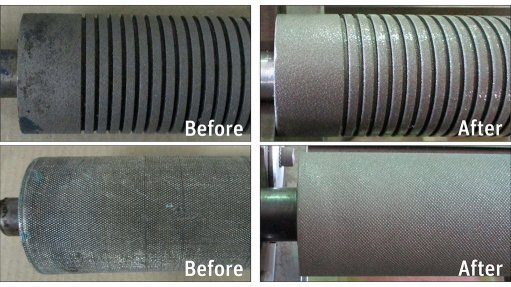

- The application of Traction / High COF release coatings on idler rolls (figure 1) and feed rolls (used for stretching or tensioning and feeding production lines) has extended the life expectancy of the components by up to three years.

- The application of Traction / High COF release and adhesive release coatings on guide rolls (figure 2) (used for guiding the blades during the cutting process of tapes on production lines), ensures that the tape stays tensioned and releases the adhesive. Rolls that have been in service for one year show no signs of wear.

Thermaspray, in a joint venture with Cape Town-based Surcotec, offers an extensive portfolio of engineering and thermal spray coating solutions that extend component life cycles to assist OEM and end-user clients across southern Africa in reducing costs and increasing production. The companies’ world-class quality wear- and corrosion-resistant thermal spray coatings, Plasma Transferred Arc (PTA) cladding and Polymer coatings (in partnership with Plasma Coatings USA and DIAMANT Metalplastic Germany) are augmented by a host of specialised allied services.