Company Announcement - Thermaspray (Pty) Ltd, South Africa’s surface engineering and coating specialist, is introducing thermal spray coatings in an effort to reduce erosion damage to components, equipment and systems. Thermal spraying allows the production of overlay protective coatings of a great variety of materials on a range of substrates, almost without limitations as to its components, phases and constituents. Consequently wear and corrosion resistant coatings account for significant utilisation of thermal spray processes.

“Erosion of materials and components caused by the impact of solid particles can be a life-limiting phenomenon for systems operating in erosive environments,” states Metallurgical Engineer at Thermaspray, Shaik Hoosain. He explains that while erosion testing allows an assessment of the coating toughness and adhesion, erosion behaviour of thermal sprayed coatings is not clearly understood by South African industry. Solid particle erosion is a concern for industrial plants (flow of solid particles such as coal into equipment), for aerospace systems (sand erosion on helicopter blades, jet engine blades and vanes, as well as for the power generating industry (exposure of draft fan blades to fly ash and turbines - impact of solid oxide particles on downstream blades).

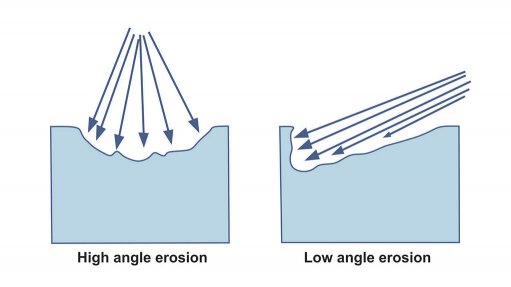

Erosion is caused when a gas or liquid carries entrained solid particles that impinge on a surface with velocity. During flight a particle carries momentum and kinetic energy, which can be dissipated during impact due to its interaction with a target surface. It has been experimentally observed that, during the impact the target can be locally scratched, extruded, melted and cracked in different ways. The surface damage will vary according to target material, erodent particle, impact angle, erosion time, particle velocity, temperature and atmosphere, etc.

Erosion rate, the material loss per unit of erodent mass or volume, vs. impact angle, is used to distinguish the two main groups of erosion processes: ductile and brittle. During the ductile erosion process (impact at lower angles), the surface damage develops predominantly by plastic deformation during cutting, extrusion, adiabatic shear and forging on ductile materials such as most metals at room temperature. During the brittle erosion process (impact at higher angles), particle impact produces different types of cracks and chipping, with negligible plastic deformation. However, Hoosain points out that on a sub-micron scale, there is evidence of plastic deformation underneath the target surface. “Other evidences suggest that erosion of materials combines ductile and brittle modes simultaneously, the ratio of them depending on impact angle and material properties,” adds Hoosain.

The erosion wastage of thermal sprayed coatings is strongly affected by particle impact angle. However, material behaviour depends on mechanisms of material removal while hardness seems to be of lesser importance. Hoosain advises that that the following factors must be taken into consideration before considering a coating for an application where erosion damage can be present:

• Angle of impact < 45°: coating should be harder and more abrasion resistant

• Angle of impact > 45°: coating should be softer and tougher

• High service temperatures: coating should have high hot hardness and oxidation resistance

• When the carrier is a liquid: corrosion resistance of the coating should also be considered

• Environmental factors such as thermal shock: erosion resistant material bond strength should be considered

Erosion resistance is complex and its combination of so many variables makes it next to impossible to duplicate and recreate field environments in laboratory tests. Thermaspray which has has pioneered the way forward in coating quality and the development of new coatings for specific applications, has designed and built a customised erosion rig according to the ASTM standard G76-13 for the erosion testing of thermal coatings by solid particle impingement at its workshop in Olifantsfontein, Johannesburg. During recent erosion rig tests conducted by Thermaspray in conjunction with a client, coatings were applied onto aluminium substrates which were sprayed using the High Velocity Oxy-Fuel spray system. Results indicated that among the materials tested, the polymers and the thermally sprayed aluminium showed the highest erosion resistance. With close to 20 years of experience, Thermaspray is well positioned to provide customers with expert advice in terms of applying the correct coating for a particular application.

Thermaspray, in a joint venture with Cape Town-based Surcotec, offers an extensive portfolio of engineering and thermal spray coating solutions that extend component life cycles to assist OEM and end-user clients across southern Africa in reducing costs and increasing production. The companies’ world-class quality wear- and corrosion-resistant thermal spray coatings, Plasma Transferred Arc (PTA) cladding and Polymer coatings (in partnership with Plasma Coatings USA and Diamant Metalplastic Germany) are augmented by a host of specialised allied services.