When economic pressure increases, companies often adopt a cautious stance. Conversely, Countapulse Controls has survived by instituting technological innovation in the face of socio-economic uncertainty.

In its more than 60 years in business, this leading supplier of sensing solutions has created a sustainable business model by focusing on anticipating and exceeding market demands. The resultant range of high quality sensing and monitoring devices has often been first to market.

Since introducing Hengstler mechanical counters to South Africa in the 1950s, the company has witnessed drastic advances in sensing and monitoring technology. Managing directors, Gerry Bryant says that it is critical for companies to keep abreast of ever developing sensing technology.

He emphasises however that all this technology is worth nothing if the technical support is not available. “The sharing of applications knowledge plays a crucial role in increasing productivity and reducing downtime, especially as many companies no longer have internal technical support divisions.”

An aggravating factor for customers is the emergence of a plethora of online shops offering sensing and monitoring technology at bargain basement prices.

“While the low prices might be an attraction, the lack of technical pre- and after-sales advice is a liability. Hi-tech items, by their very nature, require instruction for their maximised performance. It is unlikely that this level of guidance and support is available in an online shopping forum,” Bryant cautions.

In the complex process and manufacturing environments, utilising sensing, monitoring and measuring instruments that have not undergone due diligence and that do not have a great deal of reputational weight is highly risky. The failure of such products causes major production line issues and the safety around such products cannot be guaranteed.

Bryant says that the wise alternative to online shopping is one-on-one technical instruction and support. “A reputable supplier will leverage the years of hands-on experience and expertise resident in its technical staff. OEM training provides the supplier’s team with specialised knowledge and skills pertaining to specific instrumentation. By focusing on tried and tested matching of products to applications, suppliers are able to ensure best fit in all instances.”

Bryant says the company’s hotline is one way of investing its experience and capabilities back into the industry. “This product and applications knowledge is delivered as a value-added benefit to our customers.”

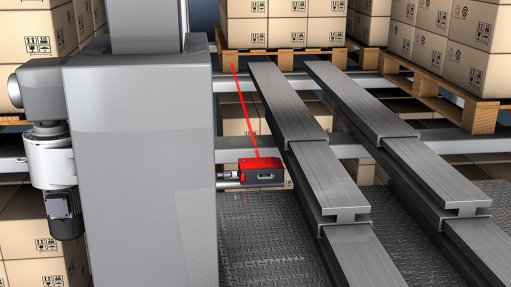

Bryant maintains that when one considers the customer’s application, it is important to understand that selecting sensors is not as simple as matching a model number to a requirement. “One needs to carefully assess the operating environment.

Parameters that should be considered include the range of the sensor, the speed of the automatic process, the background conditions and type of product, auxiliary equipment and the circuits within the process. By adopting a structured approach to selecting the most appropriate sensors or flow monitors for a given application, customers will experience enhanced operational advantages.”