South Africa’s massive backlog in affordable housing has seen a continued demand for precast hollow core concrete slabs.

“With rapid urbanisation and the increased premium on land in urban areas, multi-storey residential designs are now the norm,” says Elematic SA director Craig Webber. “This makes the use of pre-stressed concrete slabs an efficient and affordable solution, streamlining the pace of construction work while enhancing building quality and lifespan.”

Designs such as four-storey walk-up buildings are suited to repetitive construction methods and the use of precast concrete. Webber emphasises that the precast option eliminates the need for back-propping and allows other trades to start working under the slabs immediately, accelerating the project schedule.

The finish on the soffit, or underside, of the slabs reduces the need for an additional false ceiling, thus potentially lowering costs. The use of the company’s precast staircases may also help to speed-up housing projects.

“We install our precast slabs on one day and grout the next, allowing building to start on the third day without any further delay in the project timeline,” he says.

The company uses AfriSam Rapid Hard cement, which is a specialised product in the 52.5R strength class. The cement is very fine, giving it a larger surface area to react with water, which increases the rate of hydration and gives it higher early strength. This allows the manufactured concrete product to be released from the mould sooner, thus speeding up the production cycle. It also allows the production processes to be precisely timed and reduces the danger of breakage when removing products from moulds. The high early strength makes the cement brand ideal for pre-stressed members.

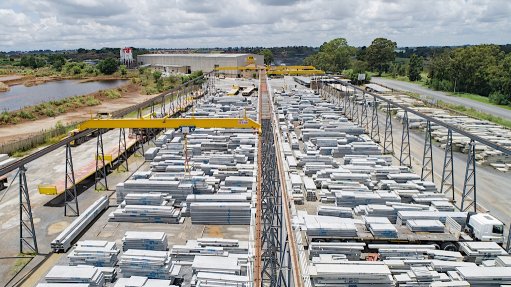

The company’s two factories have 16 beds for a variety of precast slab sizes. Its products are ISO 9001 certified and approved by the South African Bureau of Standards.

AfriSam and Elematic SA have ISO-accredited laboratories and testing equipment, with calibration of the test equipment conducted in line with South African National Accreditation System standards.

The Elematic SA facility has this year installed photovoltaic cells that will generate about 40% of its factories’ power demand.