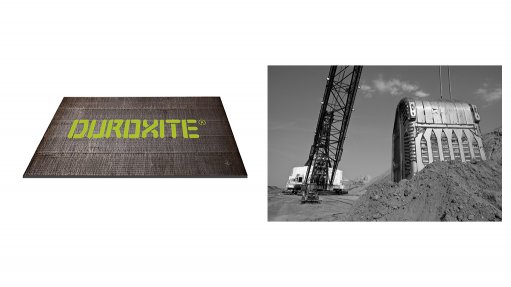

Duroxite overlay products are designed for demanding applications

Overlay products are made by welding a carbide-rich steel alloy on top of a steel plate, resulting in a compound material that has a very high resistance to wear, especially suitable for demanding applications such as sliding wear environments where small and hard materials, such as rocks or coal with high quartz content, are processed.

Duroxite chromium carbide overlay (CCO) products are engineered to safeguard equipment against wear in severe abrasive environments. Duroxite 100 overlay plate is available to SSAB’s customers in sub-Saharan Africa as full-size or cut-to-order plates.

The company says that its plates are delivered with a carbide layer thickness guaranteed within approximately 10%, consistent throughout the plate and from plate to plate.

It states that the wear properties are guaranteed throughout the plate down to 75% of the carbide layer thickness and not just to the surface of the layer. The remaining 25% is the transition layer necessary to maintain good bonding to the base plate.

Duroxite products are used in all types of wear-challenged industries, and designed to ensure high productivity and uptime. Common applications include:

• Chutes and hoppers, liners for truck beds, dozer blades, shovel buckets, dragline buckets and excavators in quarrying and mining operations

• Guide vanes, hoppers, discharge cones for clinker storage bins, and chutes and outlet ducts for clinker grinding mills in cement production

• Fan blades and housings and coke vibrating screen plates in the steel industry

• Coal handling chutes, coal feeder liners, crusher screen plates, classifier cones, journal liners and silo bunkers in power plants.

Duroxite overlay products are now available from SSAB in sub-Saharan Africa.