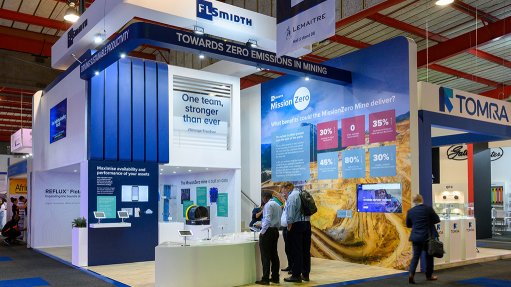

FLSmidth showcased its digital solutions at this year's Electra Mining Africa

Global mineral processing company FLSmidth says that it is leveraging digital technology to move closer to the goal of enabling net zero emissions from mining operations – referred to as MissionZero.

“Our customers recognise the value of reducing carbon emissions in plant operations, but are looking beyond a ‘big bang’ event to achieve MissionZero,” says FLSmidth VP for mining in sub-Saharan Africa, Middle East and South Asia Alistair McKay. “Rather, they are looking for a longer-term collaboration with technology partners like FLSmidth to steadily achieve sustainability goals.”

McKay highlights that progress is not based only on new capital innovations, but on the ongoing optimisation of existing equipment throughout the process flowsheet. The performance of conventional equipment such as pumps can be optimised through smart monitoring and optimisation, he emphasises.

Digitalisation is leading to greater efficiency and lower energy consumption, he explains. This includes making operational information on all equipment available in a usable format, on any device. By analysing relevant data in real time, the performance of equipment can be monitored and assessed for continuous improvement. By measuring volumetric filling and ore trajectory in real-time, FLSmidth’s LoadIQ smart sensor allows mill operating parameters to be automatically adjusted as grinding conditions change.

The company notes that mining customers at the recently held Electra Mining Africa exhibition showed keen interest in its digital solutions.