The two main reasons why concrete is the most abundantly used construction material are its durability and competitive pricing compared to other construction materials. Concrete’s durability also leads to significant reductions in maintenance costs over its service life.

“But there is still alarming ignorance about the fact that increased durability of concrete – and lower life-cycle costs - can often be achieved by following some simple rules,” says John Roxburgh, lecturer at The Concrete Institute’s School of Concrete Technology.

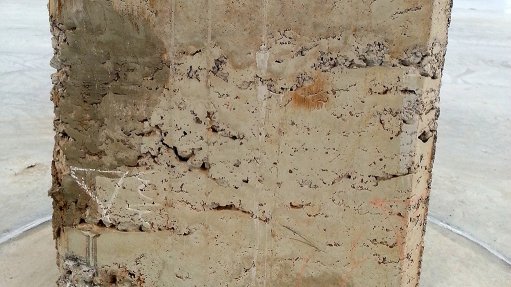

Roxburgh says although most concrete is inherently very durable, it can nevertheless be susceptible to chemical or mechanical attack or degradation. The mechanical and physical processes of deterioration could include abrasion, erosion, cavitation and freezing. “The more common chemical processes that can cause deterioration in concrete are soft or pure water attack, acid attack, carbonation (along with the associated corrosion of steel reinforcement), sulphate attack, alkali silica reaction and the ingress of crystal forming or corrosive salts. The corrosion of steel, and subsequent cracking and spalling of concrete caused by it, is the most common durability problem.”

But Roxburgh feels these concrete deterioration issues can be prevented, or at least greatly reduced, by following three simple principles:

- Firstly, the concrete mix design should be designed for the specific local environment the concrete will be used in. “If the concrete is going to be placed in sulphate bearing soil, the concrete mix design should be one that will mitigate sulphate attack. Another precaution would be the use of heavily extended cements in the mix to reduce the risk of alkali silica reaction.”

- Secondly, good on site practice will optimise the durability of concrete. Good site practice in transporting, placing, compacting, curing correctly and using concrete with the right plastic properties will reduce the formation of cracks and voids, and enhance the concrete strength, finish and durability. “Good site practice also involves the correct depth of concrete cover to protect the steel re-bars.”

- The final, and probably most important principle to making concrete durable, is to make it waterproof. “Almost all durability problems associated with chemical deterioration of the concrete or steel, as well as mechanical deterioration such as freeze-thaw and salt-crystal jacking, can be prevented - or considerably slowed down - by making the concrete impermeable to water, and to a lesser extent, gas.

- Water both transports chemicals into the concrete and causes chemical reactions in the concrete. By stopping or minimising water ingress, potential deterioration is either stopped or reduced. Gases can contain chemicals with adverse effects. Of course, the first two of the above principles are intrinsically linked to making concrete waterproof,” Roxburgh adds.