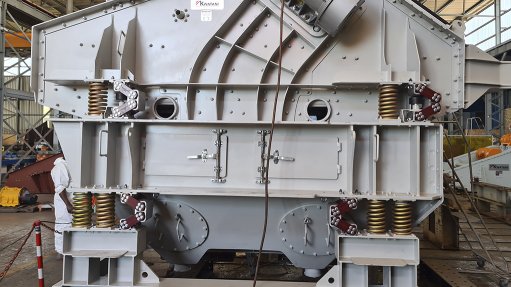

A Kwatani screen fitted with torsional springs

Screens vibrate more when starting and stopping, which can cause damage to infrastructure and reduce the lifespan of a machine. Isolators between the screen and the floor are meant to absorb vibrations and prevent damage to surrounding infrastructure, however, the transient phases of a screen can also generate considerable sideways movement, which may not be absorbed by traditional isolators.

Kwatani COO Kenny Mayhew-Ridgers says that the company has achieved considerable improvements in many screening applications by selectively fitting torsional springs alongside coil springs.

“It is well known that the vibrating motion of a screen impacts on the building and structural accessories around it,” he says. “This vibration is addressed by fitting isolators between the screen and the plant floor, and by constructing the plant building to certain minimum structural specifications.”

However, the focus is often on the frequencies that the screen generates in its steady-state phase, or the normal running phase, rather than during the transient phases when the screen is starting up or slowing down to a stop. He highlights that it is during these transient phases that the screen’s movement becomes amplified and potentially most destructive.

“Traditional isolators like coil springs usually perform well in controlling the up-and-down movement of the screen,” says Mayhew-Ridgers. “Our experience is that the sideways movement, which is induced most strongly when the machine stops, can be better controlled by torsional springs.”

He notes that coil springs are cost effective and provide a good linear isolation of the screen from the building structure and their isolation characteristics are generally better than rubber buffers, which offer better damping qualities.

“The torsional spring provides the best of both worlds, giving a good linear range for compression during operation while also becoming non-linear like the rubber buffer during stopping,” he says.

By optimising the best combination of coil springs and torsional springs, the company asserts that is has found a solution that achieves the best results for customers.

“It’s not that torsional springs are better than coil springs,” said Mayhew-Ridgers. “It is about finding the right combination – through intensive testing and adaptation – for the customer’s particular requirements; we have both the expertise and the equipment to do this.”