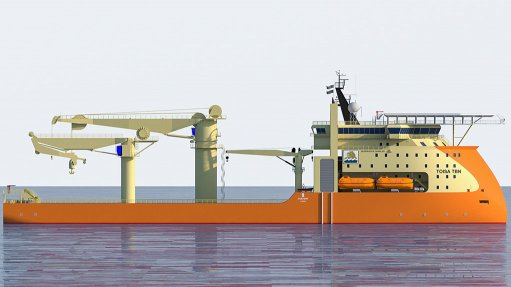

MULTIPURPOSE OFFSHORE CONSTRUCTION VESSEL Siemens integrated Siship solutions will improve the reliability and flexibility of the vessel

Photo by: Sealion Shipping

Electronics and electrical engineering group Siemens’ drive technologies division is in the process of installing its Siship integrated drive and power generation solutions for the oil and gas industry owner and operator Toisa’s multipurpose offshore construction vessel (MOCV).

Siemens is supplying the solutions on behalf of ship building company Hyundai Heavy Industries (HHI).

The MOCV is currently being built by HHI for Toisa and will be managed by global shipping and support services company Sealion Shipping.

“With this new offshore construction vessel, Toisa will set new standards in terms of flexibility and capacity,” states Siemens.

The company adds that the MOCV will be used to perform several types of offshore duties, including underwater installations up to depths of 3 500 m, construction for the oil and gas industry, the laying of undersea pipes and cables or the control of remotely operated vehicles.

Siemens states that its integrated Siship solu- tions will improve the reliability and flexibility of the vessel and reduce the MOCV’s fuel consumption and, therefore, overall running costs.

Further, the company stresses that the demands on the flexibility, efficiency and reliability of the MOCV are “extremely high”.

“For this reason, Siemens is providing the Siship integrated solutions both for marine propulsion, through the use of a Siship low-voltage (LV) drive, and for on-board power generation, through the use of the Siship medium-voltage power solutions,” states Siemens.

The company notes that the Siship LV drive is a diesel-electric drive solution, featuring components that are optimally tailored to the design of the MOCV.

Moreover, Siemens explains that the vessel’s azimuth thrusters, retractable thrusters and bow thruster are powered by five 3.4 MW and two 2.5 MW motors, combined with seven marine-type Siship frequency converters.

“The converters are specially designed for harsh operating conditions, such as ultrahigh and ultralow temperatures, vibrations and humidity levels prevalent on offshore vessels,” says Siemens.

Further, the company highlights that the optimum interaction of the vessel’s motors and converters contributes to a rapid reaction capability of the different drives, thus increasing the flexibility of the MOCV and thereby enabling it to be easily manoeuvred by operators.

“Therefore, an integrated drive system, a high level of motor performance and, consequently, a high degree of efficiency are achieved through the use of the Siship solutions,” asserts Siemens.

Additionally, the company notes that the MOCV’s on-board power supply system is fed by six diesel generators, each with an output of 4 MW.