Company Announcement - Thermaspray is an ISO 9001:2008 Quality Management System and Eskom Level 1 certified company that delivers refurbishing, manufacturing and repair services to a number of power stations around the country. As a market leader in South Africa’s Thermal Spray and Plasma Coating industries, Thermaspray’s wide range of world-class surface coating and Plasma Transferred Arc (PTA) cladding process solutions are ideally suited to a host of demanding applications in the power generation industry.

In the steam cycle, equipment and components that handle steam and water (including steam generators, pumps and turbines) operate in very harsh environments and are subjected to extreme conditions such as high pressure steam, high temperatures and wear. “These components require a variety of control, safety and shut off systems and this is where a lot of wear occurs,” says Thermaspray’s Metallurgical Engineer, Shaik Hoosain. He explains, “High pressure steam, high temperatures and metal-to-metal wear at seating areas are the main contributors of wear in steam and water valves. In addition, valve seats and spindles need to inhibit oxidation on the surface, which can lead to adhesion damage at high temperatures.”

“Our thermal spray and PTA capabilities enable us to refurbish and repair a wide range of components used by local power stations. These include fan blade and steam side spindles, servo motor and rack spindles, stator pump bearing and accumulator housings, fan blade shafts and liners, pump impellers, nose tip liners, deflector rings, control casings, sleeve and rotation plates, sleeves and bushes as well as a range of valves.”

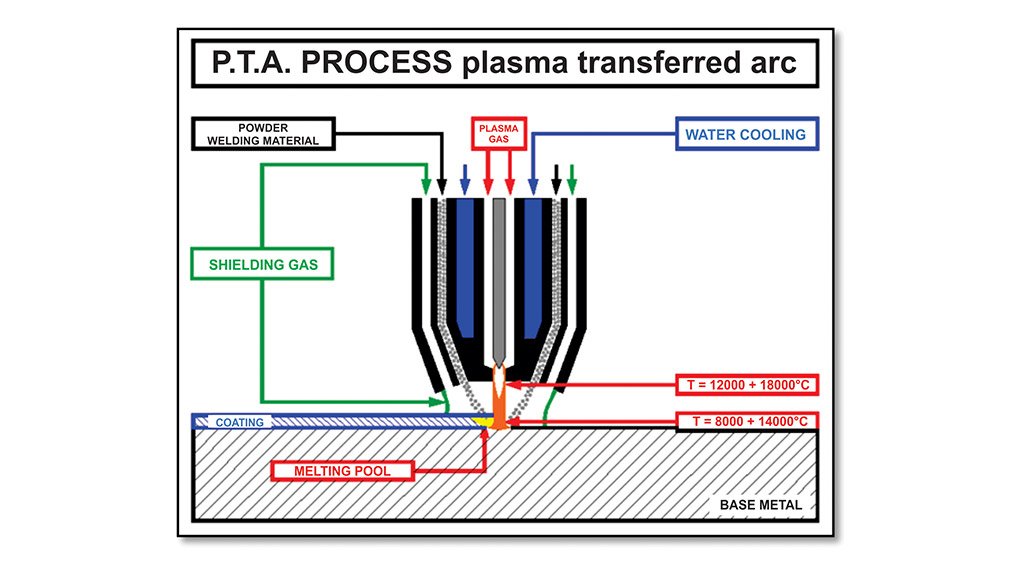

Thermal spray is the method of applying materials onto a prepared base material by heating particles in the stream of a heat source to create a semi-molten state. Particles are then propelled by high velocity onto a prepared substrate where they adhere to the base surface via a mechanical bond; particles continue to build until a specified thickness is attained. This spray method, which is considered the ‘cold method of welding’ where high temperatures can be achieved in the heated pocket while the temperature of the part itself usually remains under 100°C, restores worn components to precise original dimensions. Thermal spraying provides increased resistance to high temperatures and oxidation, traction, cavitation, chemicals and corrosion as well as wear resistance (resulting from erosion, abrasion and sliding).

“The result is an extension of component service life and the subsequent increased uptime and improved production translate to significant cost savings for the end-user,” notes Hoosain. PTA weld / clad hardfacing offers the ideal solution for applications, where severe impact and corrosion are prevalent, that require a coating that can withstand such conditions by providing the necessary protection to the substrate.

“This welding process is used to produce high-quality weld hardfacings of Ni, Co and Fe alloys, as well as tungsten carbide containing grades of the nickel alloy,” comments Hoosain. ”The PTA hardfacings that are metallurgically bonded to the parent material, are able to handle impact, point and/or line loads that a thermal spray coating cannot tolerate.” Hoosain discusses the scope of work for various repairs and refurbishments conducted by Thermaspray at eight power stations: “We completely refurbished Semple Valves which involved stripping of the valve, pre-machining, stress relieve, thermal spraying, PTA welding, NDT, final machining, final grinding, and assembly. We also manufactured rings and bushes for the Semple valve from Mehanite material to the client’s specification.” “The refurbishment of valve spindles in partnership with a business partner included pre-grinding, thermal spray coating, final grinding, and NDT on the coating. The repair and refurbishment conducted on gland boxes demanded pre-machining, thermal spray coating, final machining, and final grinding.”

“To refurbish valve seats we did pre-machining, PTA welding with a Co alloy, and finally, machining to the required dimensions. We also did PTA welding on new seats. Our pump refurbishment, which was completed with a business partner (Sulzer), included machining, grinding, thermal spray coating, and final grinding. Electrical run outs have also been conducted on these shafts ensuring the quality required. We also coated butterfly and ball valves to increase wear and corrosion resistance,” concludes Hoosain.

Thermaspray, in a joint venture with Surcotec, offers an extensive portfolio of engineering and thermal spray coating solutions that extend component life cycles to assist OEM and end-user clients across southern Africa in reducing costs and increasing production. Based in Gauteng and the Western Cape respectively, Thermaspray and Surcotec’s world-class quality wear- and corrosion-resistant thermal spray coatings, Plasma Transferred Arc cladding and Polymer coatings (in partnership with Plasma Coatings USA and Diamant Metalplastic Germany) are augmented by a host of specialised allied services. These include coating finishing technologies such as machining, grinding, diamond grinding, probe track burnishing, electrical run out measurements/reporting, linishing, and super finishing.