Using a unique matrix design, the FerroCer® impact wear panel from FLSmidth combines the strength and malleability of steel with the superior abrasion resistance of ceramics to extend the availability of crusher chutes and hoppers.

These modular panels are designed to offer the longest possible wear life, extending production cycles and bringing down cost per ton at hard-mineral mining operations. Use of these panels will reduce maintenance shut-downs, operational downtime and operating costs.

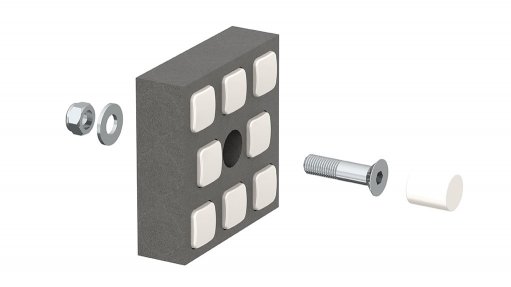

Each FerroCer panel is made up of a set of abrasion resistant ceramic inserts enclosed in a matrix of malleable steel, with the matrix ensuring that only the top surface of the inserts is exposed to material impact. Within the matrix, the sides of the inserts are tapered to keep them in place and to prevent material particles and fluids from damaging the panels.

The panels’ low weight and compact size makes them safer and easier to install than typical bulky wear liners, and only standard hand tools are required. Avoiding the need for heavy lifting equipment speeds up maintenance and cuts production downtime.

Each compact panel weighs just 5 kg while the edge panels just 9 kg, making them easy to lift and to handle. This ensures that they are compliant with manual handling requirements in terms of occupational health and safety.

FerroCer panels are also simple to install, with each panel attached using a single countersunk bolt. Using the two types of panels – the standard panel for most of the chute’s surface and the elongated edge panel for the chute’s entry and exit points – an entire chute can be lined for longer uptime.

The edge panels can also be trimmed if there are irregular shapes or corners in an installation that need to be accommodated.

Along with offering the lowest total cost of ownership, the longer wear life of FerroCer panels reduces their environmental footprint by translating into less material input and less waste.