F-CLASS FIRE KITCHEN SYSTEM Designed for kitchen areas in hotels, restaurants and public institutions

Electric and gas operated equipment in kitchens, which uses large amounts of flammable ingredients, is susceptible to ignition and a fire break out, says protective fire equipment provider Centa Group chairperson Duncan Boyes.

“Cooking oils have high ignition tempera- tures and spontaneously combust at about 360 ºC, which makes them difficult to extinguish. To safely extinguish a cooking oil fire, the oil needs to be cooled down and smothered.”

Centa Group’s complete range of fire protection systems, which is continuously being improved, encompasses the UL approved kitchen fire suppression system, designed especially for kitchen cooker hoods in hotels, restaurants and public institutions.

The kitchen suppression system meets UL quality and safety standards and has enhanced the safety of commercial and industrial kitchens.

The system makes use of Centa’s F-Class fire extinguisher which contains a wet chemical that is biodegradable and nontoxic, based on potassium salts. This chemical cools and extinguishes oil fires that ignite at 350 ºC.

On contact with the hot oil, the liquid forms a foam, which prevents oxygen from reaching the fire, at the same time cooling the oil. Unlike conventional fire suppressions systems that contain potassium carbonate, this system has a low acid level of pH:9 and is not harmful to food products and does not damage appliances or stainless steel surfaces.

Certain dry chemical powder extinguishers knock down an oil fire, but they have no cooling capabilities, thus the risk of the fire reigniting is high.

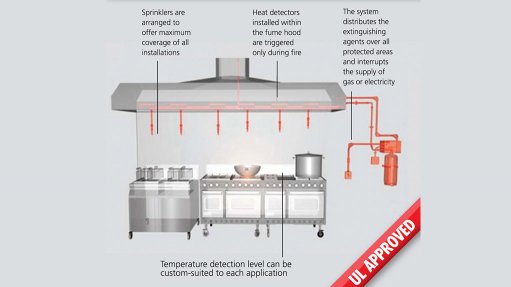

Centa’s kitchen suppression system distributes the extinguishing agent over all protected areas and can automatically shut off the supply of gas or electricity. Heat detectors, which are installed within the fume hood, are triggered only during a fire.

Although this system is automatically activated in the event of a fire, there is also a manual override facility. Temperature detection levels can be adjusted to suit specific applications and nozzles are installed to ensure maximum coverage of the kitchen area. All components have been designed for enhanced aesthetics and workspace efficiency.

For optimum safety and total reliability, Centa Group stresses that the system be installed by a trained and certified Centa Group technician.