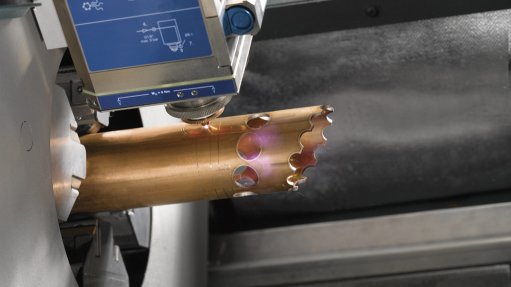

BLM TUBE LASER Fibre laser technology is a cost-effective option for the steel industry

Cutting solutions provider First Cut is supplying fibre laser cutting machines to South Africa, which are greatly improving the efficiency and cost effectiveness of laser-cutting operations in various industries, including the steel industry, in a difficult economic climate.

The machines provide a fibre laser solution for cutting tube, pipe and nontubular open sections, as well as sheet metal and thicker plates of various materials. First Cut MD Andrew Poole notes that the new technology has been very successful in Europe, owing to the machine’s accuracy, versatility in terms of the range of metals and thicknesses that it can process, and greatly enhanced speed of processing.

He adds that fibre laser technology has usurped traditional carbon dioxide (CO2) laser technology because of these benefits and its ability to reduce power consumption by about 30%.

Moreover, he mentions that First Cut is constantly looking for a wider market and diversification opportunities.

“We have found the renewable-energy sector . . . and automotive industry to be particularly buoyant at present,” Poole says. Further, he notes that many companies are finding it necessary to implement aggressive cost-management systems, and the laser-cutting technology First Cut provides is well-aligned with these, owing to the operating-cost savings these machines allow.

The company supplies laser-cutting machines for flat sheet metal, developed by its principal, sheet metal processing systems manufacturer Bystronic, in Switzerland. These machines are extremely versatile, as they can process ferrous and nonferrous metals, including stainless steel, aluminium, copper and brass.

First Cut is also supplying fibre tube laser-cutting technology, developed by its principal laser-cutting machines manufacturer BLM Group, in Italy. These machines offer a three-dimensional cutting process that makes cutting quick and versatile. They have particular application in the automotive industry, but are also used in a wide range of other sectors such as aeronautical applications, renewable energy, industrial and office furniture.

The company has supplied various laser-cutting machines to companies in South Africa, including fabricator and processing specialist TWTLP, bulk container manufacturer Welfit Oddy, steel merchant Steelrode and steel products supplier Qinisa Steel, and is looking to further expand its client base with these new offerings.

“We believe that as soon as our customers start to realise the exciting possibilities inherent in fibre laser technology and the real benefits it brings to the bottom line, its use will become increasingly widespread and prevalent,” concludes Poole.