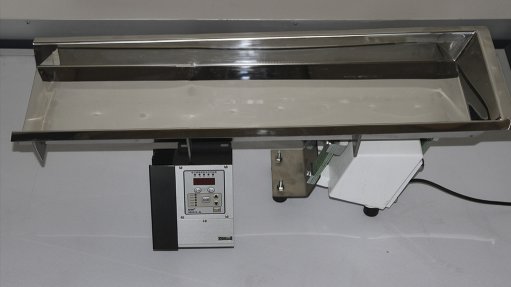

GOOD VIBRATIONS The electromagnetic feeder requires only one drive and is quieter than other drives on the market

Last month, engineering consultants Vipro Vibrating Products announced the arrival of its first locally incepted light industry electromagnetic feeder prototype.

The prototype feeder was incepted by Vipro in May through a collaborative effort by design and technical teams, and is currently in the testing phases of production.

Subsequently, the feeder will be available for purchase by the end of this month.

The feeder is designed for applications in the light industry, including fast-moving consumer goods, agriculture, clothing, pharmaceuticals and plastics.

The new feeder will not only allow for a variety of bespoke trough configurations but also cost less than an imported feeder of similar size or capability. “The feeder will cost our clients as much as 20% less than other similar electromagnetic feeders,” boasts Vipro international sales and marketing manager Pieter Uys.

He adds that the trough will be manufactured at the Vipro head office to client specifications, while the drive and control box will be imported from Asia.

“The trough can be manufactured in different configurations – such as straight or V-shape troughs, left and right outlets, straight outlets as well as outlets that cater for a ‘drop-in’ product source – and also include a trough cover for strict hygiene and dust-free applications,” says Uys.

He adds that a mesh plate can be used in the trough as well for facilities that require a dewatering capability for their plant.

The troughs are furnished in mild and stainless steel, and can be finished to order with teflon, urethane, rubber or other application-specific coatings.

The electromagnetic drive on the feeder allows for a 100% control capability, as opposed to an electromechanical feeder, which is limited to about 50% control. Uys points out that this is necessary when a client needs to have control across the full spectrum of tons being moved through the feeder.

He adds that an electromagnetic feeder requires only one drive, which uses a magnetic coil to generate the forward movement over the trough, compared with the two drives required by an electromechanical feeder to create the required linear motion to allow for movement of the product.

An electromagnetic feeder is sold standard with a control box, which facilitates a better degree of operational ease; an electromechanical feeder requires a frequency inverter to control the two motors and the output they deliver.

A further benefit of the electromagnetic feeder is its lower noise levels, which is beneficial in situations or applications where noise regulations apply.

“The electromagnetic feeder will be faster, cleaner and almost maintenance free, in addition to being more cost effective, which is exactly what the South African market currently needs,” concludes Uys.