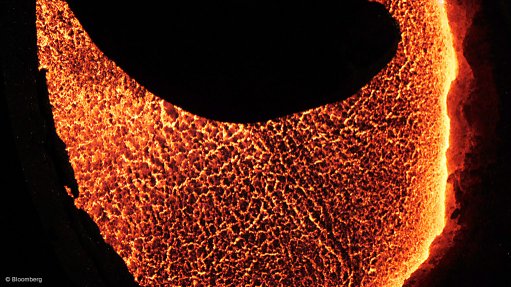

Photo by: Bloomberg

JOHANNESBURG (miningweekly.com) – A definitive feasibility study (DFS) at pig-iron developer Ironveld’s Limpopo-based pig iron and ferrovanadium play has confirmed the project’s ability to deliver an “exceptionally” high-grade 99.5% iron product called high-purity iron (HPI), which commands a premium to the price of conventional pig iron.

The DFS assessed the economic viability of a project boasting a 15 MW direct current smelter with planned production of 41 966 t/y of HPI, 415 t/y of vanadium in slag and 8 269 t/y of titanium in slag, from late 2015.

The study confirmed a highly scalable project with a life in excess of 100 years with the ability to deliver a yearly turnover of £26.4-million and earnings before interest, taxes, depreciation and amortisation of £8.1-million a year.

The project was also projected to be cash flow positive from the start of production, with capital expenditure projected to be some £36-million – a proportion of which would be funded from early cash flow of the project.

The DFS further confirmed that the tenement held vanadium and titanium slag containing commercial grades of vanadium and titanium, while ore from the main magnetite layer on the company's properties could be fed directly to the proposed smelter without the need for beneficiation.

In addition, 20 MW of power would be available on site by the end of the year from an Eskom substation adjacent to the project area.

Ironveld said in a statement on Wednesday that the “robust nature” of the project had attracted interest from a number of capital providers, adding that the company was in advanced discussions with banks, financial institutions and industry stakeholders who were interested in providing the necessary capital as part of capital equipment or offtake agreements for the project's HPI, vanadium and titanium.

CEO Peter Cox added that the company had tested its products with potential end-users and had generated “significant interest”, particularly for the HPI.

“The ability to sell the titanium slag has also added to the project's robustness.

This is a very exciting time for Ironveld and we remain on track to start construction later this year, with first production scheduled for late 2015,” he said.