Global leader in industrial gear systems design, manufacture and service, David Brown has been delivering highly reliable gear systems to the mining industry for more than 150 years. From CX conveyor drives, large girth gears and mill drives to complete gearbox service, repair and upgrade, David Brown is the mining industry’s local engineering partner.

David Brown gear systems are also used in applications in the energy and metals processing sectors as well as many other industries.

The company’s mining gear centre of excellence in South Africa is located in Benoni, Johannesburg. However, the company has three additional manufacturing sites in the UK, France and Canada, as well as 15 service and repair centres. David Brown serves customers worldwide with gear engineering, manufacture and service.

The company supplies gears, gearboxes and drivetrains for a number of mining applications, including conveyors, semi-autogenous grinding (SAG)/autogenous grinding (AG) and ball mills, stacker reclaimers, agitators, and shovel and dragline vehicles. Its core mining products are CX conveyor drives, MDX mill drive systems and cast/fabricated girth gears.

CX Conveyor Drive Gearboxes

David Brown’s CX conveyor drive series is a core platform of gearboxes designed specifically for belt conveyor applications, with a number of special features. The company knows that high thermal ratings and long bearing lives are key to its customers’ successful operation and CX is engineered to operate in ambient temperatures of more than 45 °C as well as deliver a minimum 60 000 hours of bearing life.

Additionally, its new ribbed case and high-performance fan design delivers optimal self-contained cooling without the need for an external cooling system. This ensures customers have reliable performance at full load – even at the highest ambient temperatures.

Mill Drives

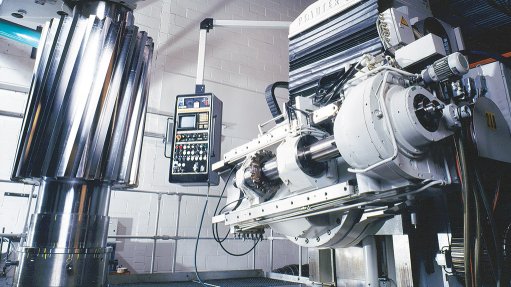

David Brown’s MDX range covers all elements of a mill drive system, from the gearbox through to the girth gear, pinion and auxiliary equipment. The MDX range can be supplied as a fully optimised system or as individual components.

David Brown’s mill drive gearbox is readily adaptable to meet the needs of all applications in the mining industry, including SAG and ball mills. Single-, double- and triple-reduction gears are available, depending on customers’ required ratios and motor speed. All mill drive gearboxes are engineered to complement the girth gear and pinion to reduce costs and ensure reliable operation.

Girth Gears

David Brown delivers both cast and fabricated girth gears for AG, SAG and ball mill applications through its extensive experience in cast and fabricated gearing.

David Brown has in-house manufacturing capability in Benoni for gears up to 14 m diameter and over 100 t in weight, as well as a supply chain to support manufacture in cast or fabricated steel, or ductile cast iron. The company meets all girth gear requirements, whether part of a complete mill drive system or an individual com- ponent.

Successful production of reliable girth gears needs expert control of the material manufacturing process. David Brown operates proven quality management processes which cover production of cast steel, cast SG iron and fabricated girth gears.