CNC WATERJET CUTTING The brittle cutting process gives a satin finish, with no slag or heat affected zones

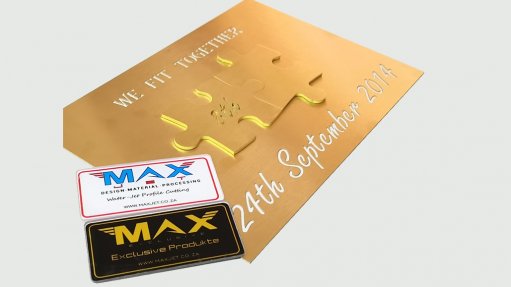

Local water-jet cutting service provider MAXJET will be launching a new online store in early 2024 for an extensive catalogue that specifically targets clients abroad, owing to the weaker rand.

“Once we have launched our store, we expect our MAX Exclusive range to expand considerably, taking full advantage of the weaker rand for exports,” enthuses MAXJET director Preeshan Naidoo.

MAXJET offers a unique service for industrial cutting, with the company having “mastered the various parameters for processing almost all types of flat-sheet products”. These products include aluminium, titanium, stainless steel, carbon steel, plastics and composites.

Naidoo attributes this ability to more than 20 years of experience.

“From a design perspective, we are capable of replicating parts from samples, and sketches into computer-aided drawing, as well as further programming to profile cut,” he explains.

MAXJET uses computer numeric control (CNC) water-jet cutting and profiling technologies to cut various material types, with thickness ranging from 0.05 mm to 100 mm.

CNC water-jet machining is a nonthermal cutting method, which uses abrasive garnet sand and water.

The brittle cutting process gives a satin finish surface, with no slag or heat-affected zones, consequently minimising distortions.

Water is filtered and pressurised in an ultrahigh-pressure pump and delivered through a high-pressure tubing to the cutting head.

A small-diameter orifice will concentrate on the CNC jet machine, and the pressure transfers into velocity.

CNC jet machining is also ideal for preparation of parts before milling.

The supersonic water stream cut process also enables MAXJET to cut different flat-sheet materials and complex shapes, from prototypes to mass production.

The key benefits of MAXJET’s cutting and profiling process is that, when processing materials, the company’s technology involves a “cold cutting process”, which ensures that the inherent material structure is not compromised by any “cheaper” thermal processing, Naidoo states.

Vital Material Supply

To support the company’s cutting and profiling capacity, MAXJET has put considerable effort into partnering with an approved network of suppliers.

These suppliers are vital for supporting MAXJET’s services in terms of supplying raw materials that are used for the company’s processes.

“We’ve partnered with material suppliers EMV Africa Multi Alloys, which specialises in stocking superior grades of nickel stainless steels. These steels have high success rates at water treatment plants, chemicals processing plants and petrochemicals industries.”

MAXJET plans to increase its capacity by adding more equipment to its cutting and profiling setup.