GOOD CARMA The production of renewable, cost-effective alternatives to petrochemicals commonly used in the production of plastics, resins and composites within the automotive industry

A consortium led by sustainable technology innovator Sonichem has been granted nearly R14.6-million in funding from UK government agency Innovate UK’s 'Resource efficiency for materials and manufacturing' (REforMM) programme.

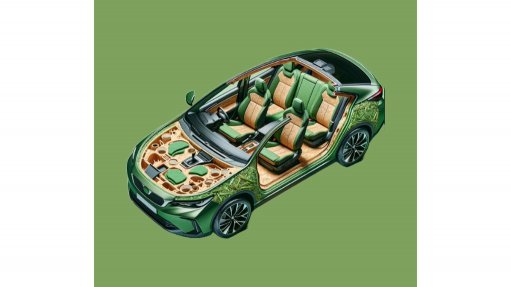

The funding will accelerate the development of the proprietary Sonichem ultrasound technology and the production of renewable, cost-effective alternatives to petrochemicals commonly used in the production of plastics, resins and composites within the automotive industry.

The “cutting-edge” carbon-neutral agroforestry-derived resins-to-materials for automotive applications (CARMA) project will apply Sonichem’s ultrasonic processing technique to automotive applications for the first time.

The patented breakthrough approach converts sawdust, the biomass by-product from forestry operations, into high-quality lignin.

This renewable material will then serve as the basis for biobased platform chemicals, creating green alternatives to conventional petrochemical-derived materials currently used to produce various vehicle components.

This transformative initiative is being undertaken in collaboration with technology innovation catalysts CPI, the National Composites Centre (NCC), chemicals company Scott Bader, advanced composites manufacturer SHD Composites and automotive manufacturer Polestar.

Each industry leader will contribute its own specialised knowledge and expertise.

In particular, CPI will support scale-up of the Sonichem technology; Scott Bader will pioneer the development of high-performance, sustainable composite resin formulations; and the NCC, SHD Composites and Polestar will together explore the potential of these novel materials for automotive interiors applications.

The CARMA project aligns with the UK government’s focus on resource-efficient, sustainable industrial materials as it aims to significantly reduce the UK’s reliance on imported composite materials, which currently amounts to between R6-billion and R6.3-billion a year.

The newly awarded funding from Innovate UK will enable the international consortium to establish a robust and renewable lignin supply chain within the UK and accelerate the formulation of sustainable plastics and resins that contribute to steering the automotive industry toward a net-zero future and enhancing the UK’s bioeconomy.

“We’re extremely pleased to have the backing of Innovate UK’s REforMM programme for this strong industrial consortium,” says Sonichem CEO Adrian Black.

He adds this funding is a catalyst in its quest to offer the automotive industry a sustainable alternative to petrochemical- derived plastics.

“Creating a sustainable future is at the core of our mission,” says NCC verification manager David Fishpool, adding the NCC is proud to be part of this transformative initiative to accelerate the development of sustainable, cost- effective alternatives to petrochemicals in the production of plastics, resins and composites for the automotive industry.

He adds NCC’s role in this project underscores its commitment to driving innovation and sustainability in the materials sector, and it eagerly anticipates contributing its expertise to this “vital effort today, for a greener tomorrow”.

“Scott Bader is pleased to be part of this exciting project, and we look forward to working with our highly regarded industrial and technology partners to accelerate the valorisation of abundant and sustainable biomass towards high-performance materials,” says Scott Bader group sustainability technology manager Steven Brown.

Finally, SHD Composites technical director Nick Smith says the company is excited to be working with Sonichem on the next generation of sustainable resins wholly sourced from UK feedstocks as part of its ongoing commitment to reduce the ecological impact of its products.

“These materials have the potential to be a game changer in the high-value composites market,” Smith concludes.