Work starts on Msikaba bridge deck

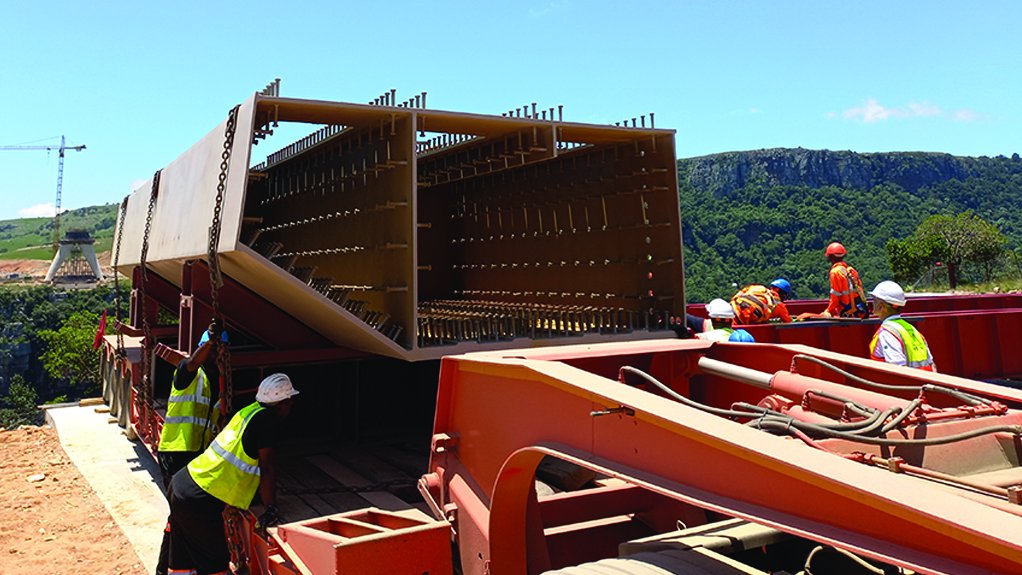

Work has started on the Msikaba bridge deck, the South African National Roads Agency Limited (Sanral) reports, noting that it took three trucks to transport the first steel bridge deck segment in three sections from Middelburg, in Mpumalanga, and three to five hours to offload each segment at the construction site, near Lusikisiki, in the Eastern Cape.

The 580 m Msikaba bridge will cross the 195 m deep Msikaba river gorge and, once completed, will be the longest span cable-stayed suspension bridge in South Africa and the second longest in Africa after the 680 m Maputo-Catembe bridge, in Mozambique.

The anticipated completion date is the end of 2024, Sanral says.

The bridge forms part of the backbone of the greenfield portion of the N2 Wild Coast Road project (N2WCR) – a national priority under the coordination and direction of the Presidential Infrastructure Coordinating Commission (PICC) and one of government’s 18 Strategic Integrated Projects (SIPs) to support economic development and address service delivery in the poorest provinces.

The bridge deck is the part of the bridge that will hang out over the gorge that traffic will drive on, to cross from one side to the other.

“This is quite a milestone. For a cable-stay bridge, a huge amount of work precedes the construction of the bridge deck itself. Much of which is hidden from sight,” says Sanral N2WCR project manager Craig McLachlan.

“The pier includes its major foundations to support the downward pressure from the cables, as well as the abutment and gallery next to the piers, this is where the deck starts and is joined to the base of the pier.

“The two massive anchor blocks on each side, each half a soccer field long and buried four storeys into the ground, all must be substantially complete before work on the deck extending out over the gorge can start,” he explains.

The second segment will be transported from Mpumalanga to Msikaba in January.

The entire deck comprises 36 segments, with 18 segments on each side. Each segment is made up of two box girders and two truss girders. It takes three trucks to transport each segment and, in total, it will take 108 truck delivery trips, including four abnormal loads for the four boxes for segment zero at North and South sites.

Segment zero on each side is not connected to any cables but is attached to the abutment and supported from below until it is connected upward to segment 1. Segments 1 to 17 on each side each have two cables (attached one on either side). Each box segment will be supported or held up via these two cables leading up to the 127-m-high pier with two corresponding cables connected back down to the anchor blocks.

“With the exception of segment zero which can be assembled in situ, each segment will be assembled on the bank, then carried between the legs, launched out above the gorge, rotated 90°, brought back and attached to the proceedings segment, or for the first segment to the embankment.

“The segment then has two cables attached, one on each side. The cable is attached to the spire and another corresponding set attached to the anchor block. A thin steel and concrete composite deck is then cast. The process is repeated till the decks meet in the middle,” McLachlan outlines.

All steel used to manufacture the material for the deck is 100% South African, Sanral points out.

The deck segments are being constructed (cut and welded) in Middelburg, Mpumalanga.

The first four big boxes will be transported using abnormal loads, but the girders and remaining boxes can be delivered using normal trucks.

Abnormal loads cannot travel through KwaZulu-Natal over most of December; therefore, the second box can only be delivered in January.

When joined together, the two large boxes on each side of the deck segments will form two separate 290 m long box girders that provide the longitudinal support and stiffness for each half the bridge. This means there will be a joint at the midpoint of the bridge so each half of the 580 m long bridge are independent structures.

The smaller truss girders linking the boxes are stiff compound steel structures that provide the main cross support between the longitudinal box girders and provide twisting stiffness or rigidity.

Together the longitudinal box girders and cross truss girders form a very large ladder shaped steel structure upon which the (combination steel and reinforced concrete) deck plate lies and upon which the four-lane highway will run.

Once completed, the Msikaba bridge is expected to play a crucial role in improving travel time, connecting previously divided communities in the region, and opening opportunities in business and community-based tourism for the Wild Coast.

The completed road is also expected to improve the travel time between Durban and East London by up to three hours for heavy freight and, by providing a high mobility route through an area that is extremely isolated and under-served by road infrastructure, the route will have significant social and economic benefits and will act as a catalyst for local and regional development, Sanral says.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation