Weba South America Gives Region Access To Custom Engineered Chute Systems

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Following increased market demand and extensive investigative time on the ground, Weba Chute Systems has announced the establishment of Weba South America. The company exhibited at Expomin Chile under this new banner.

Mark Baller, managing director of Weba Chute Systems, explains that South America has long been considered a key growth area for this leading OEM of customised chute systems. “Establishing a new operation, especially in a foreign country, is not something to be taken lightly and it was essential to satisfy ourselves that it would be both viable and sustainable when we entered this market with local representation,” he says.

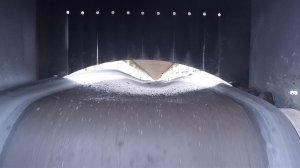

South America, not unlike other developing regions, has an increased focus on health and safety requirements within the mining industry and transfer points have been identified as an area that must be addressed. Weba Chute Systems has a solid reputation across the globe for providing transfer point systems that not only ensure optimum throughput, irrespective of the material being transferred, but also minimise spillage, dust and material degradation.

Weba South America’s first office has been opened in Santiago, Chile and will be managed by an onshore service provider, Rhomberg, with the appointment of Pedro Javier Vega in the capacity of technical advisor. The prime focus for Weba Chute Systems in setting up the facility was to have local representation and to ensure that the local team has a good understanding of the mining industry and its immediate and long terms needs. It is also considered critical to be able to understand the region language and culture. Baller says that while the operation will be small initially, the intention is to expand as customer needs drive the process.

Local manufacture of the patented Weba Chute Systems will be done by carefully selected third party manufacturing operations, with the design and engineering work being done by the experienced Weba Chute Systems team in South Africa. Baller is quick to point out, however, that in the long term the OEM will invest in the region by developing its own design, engineering and manufacturing facilities.

“A comprehensive local footprint is our long term goal in Chile, with all the necessary skills and resources based in the region to cater for the customer base,” Baller says. The operation in Chile will be used as the springboard into other South American countries such as Argentina, Peru and Brazil.

The move has certainly paid off for Weba Chute Systems as Baller confirms that the South America office has received its first tender to conduct an engineering study at one of the largest copper mines in the region. “This will be to do a study on over twenty transfer points and given the depth of expertise and experience that Weba South America can access from Weba Chute Systems it is well positioned to undertake this project which will look at optimising current chute designs at the mine thereby improving throughput and performance,” Baller says. “An obvious advantage when achieving optimisation of any transfer point will also be a reduction in maintenance and operating costs. This could be through modification and optimisation of the existing transfer points or the complete replacement with custom engineered Weba Chute Systems,” he concludes.

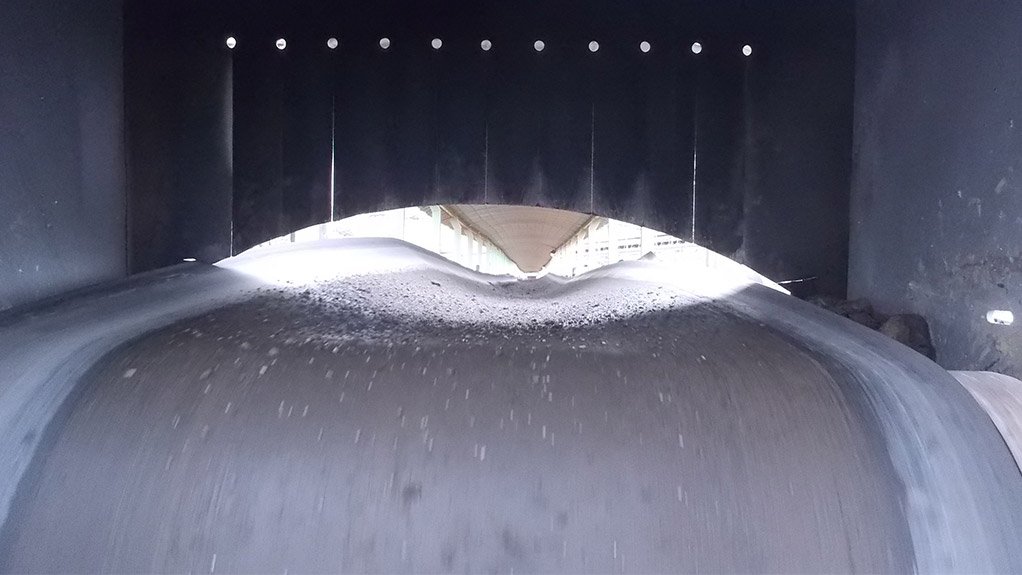

The Weba Chute System uses a streamlined scientific approach to the dynamics of bulk materials handling taking all aspects such as belt speed, belt width, material size, shape and throughput into account. The custom design allows control of the direction, flow and velocity of a calculated volume and type of material in each individual application. There are more than 4 000 of these custom engineered chute systems operating successfully across the globe.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation