Utilizing High-Volume; High-Head; Medium/High Voltage Submersible Pumps For Acid Mine De-Watering

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

The harsh mining conditions in Southern Africa require submersible pumps to pump high volume of liquid containing solids at high heads and which have led to the design and development of the world’s first Medium/High Voltage Submersible Slurry Pump capable of pumping high volumes of liquids containing solids, at high heads.

HAZLETON PUMPS has launched the HIPPO Range of High-Head; High-Volume; Medium/High Voltage Submersible Slurry Pumps that is capable of pumping liquids that contain acidic solids.

Utilizing Medium/High voltage power supply submersible pumps with an installed power of up to 2500kW have been developed for both 50Hz as well as 60Hz power supply. The design has been developed as a result of the success of the Medium/High Voltage; High Volume submersible slurry pump that was first developed in 2005 and exported to the Oil Sands Mines at Fort McMurray, in Alberta, Canada.

The HIPPO Submersible Slurry Pump ready for export to the Oil Sands Mines at Fort McMurray, Canada

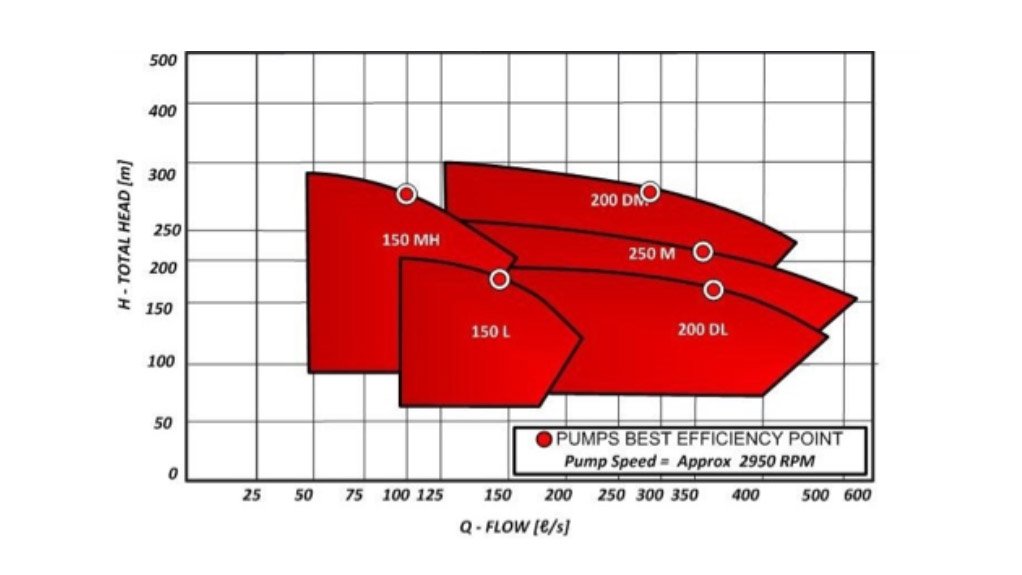

The High-Volume; High-Head pump range at this stage consists of five models designed to operate at 50Hz and the curve below indicate the best efficiency points:

The HIPPO High-Volume; High-Head; Medium/High Voltage Submersible Slurry Pump Range utilizes a single stage impeller operating at 2-pole speed (2950 RPM) and is manufactured from specialized material that is capable of pumping acidic liquids containing solids.

The proven HIPPO Submersible slurry pump design with the standard configuration has been used for the pumping of high volume liquids containing solids with the main feature of the HIPPO configuration being the Twin Volute Discharge balanced thrust design in which all the radial forces on the Impeller are balanced out, resulting in lower loading on the bearings.

The Motor Housing is oil filled similar to that of a transformer – this assists the dissipating of heat away from the Electrical Windings thus allowing the pumps to run dry continuously. The oil also lubricates the Bearings and the Mechanical Shaft Seals. Double Mechanical Shaft Seals are used with the lower seal in a separate oil chamber. Utilizing the cantilever Shaft design the Mechanical Shaft Seals are at submergence pressure and not at the pump discharge pressure – which is the case in most other submersible pump configurations.

The standard Material of Construction of the Hydraulic End is 28 % Hard Chrome with the rest of the castings being Mehanite CB3, giving the pump the ability to pump abrasive slurries, with an acid content with a pH of 4 and above. For acidic conditions (lower than a pH4) specialised Materials are used such Duplex Stainless Steel.

The design also includes probes that has been installed close to the Mechanical Seals which monitors the conductivity of the oil. Should the Mechanical Shaft Seals wear and start to leak, the oil gets contaminated and the probe will detect the change in resistance of the oil and switch the pump off before the Electrical Winding fails.

The major failure of submersible Pump is due to the Electrical Winding of the submersible pump failing as a result of the failure of the Mechanical Seals, which allows the slurry being pumped to come into contact with the Electrical Winding. Rewinding of the Stator contributes to more than 50% of the total repair cost and if this could be avoided the total cost of ownership is drastically reduced.

The major application would be the use in acid mine de-watering and the pumps can be connected in series to achieve any desired head and is specifically used in mine de-watering application at shaft bottom.

Underground flooding is a reality and the High-Volume HIPPO Submersible Slurry pump is well suited for these conditions. Using the medium voltage power of 3.3 or 6.6. kV the pump could be switched on and controlled from the surface or an alternative dry location.

Utilizing the Stepped Impeller Intake Sealing System (which have been trademarked with a patent pending) with centring bush and balancing rings the challenges mentioned above are overcame. The research was done in 2015 with trails successfully completed on the smallest HIPPO submersible pumps available.

The principle is that Impeller Outer intake shroud is designed with a minimum of three steps, one of which is the centring bush that limits leakage from high pressure impeller discharge back to low pressure impeller intake to a minimum.

The impeller is also fitted with a minimum of one pressure balancing ring at the bottom of the shroud of the impeller so as to limit the axial forces on the impeller to a minimum. A second balancing ring is fitted to the top and bottom shroud as close to the impeller discharge as possible.

The design is based on changing the flow direction by 90o with minimum clearance as many times as possible to reduce the pressure across the steps and this principle applies to both the Impeller intake as well as to the pressure balancing rings.

Utilizing a balanced impeller with equal number of vanes in a double discharge volute casing will eliminate vibration of the impeller. Having a fixed bearing arrangement, as close as possible to the impeller, axial movement will be eliminated on the impeller which could be caused by thermal expansion of the shaft. The flow dynamic in the hydraulic end was confirmed by measuring all parameters required to evaluate the flow dynamic after completing the trails.

To contain the high inflow rate of solids that will result in a high wear rate of the impeller the flow must enter the pump from the top of the hydraulic end and the design of the rotor and stator of the pump must comply with the standard Electric Motor specifications to ensure the best efficiency. Since the pump will also be used underground and in the possible presence of methane gas, the pumps must comply with Flame Proof IEC 60079-1 specifications.

The success of this research and development of the High-Volume; High-Head; Medium/High Voltage; HIPPO Slurry Submersible pump has led to HAZLETON PUMPS being a world leader in the supply of this product – with no other pump manufacturer having a similar product available.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation