Transfer Points Can Contribute To High Maintenance Costs

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

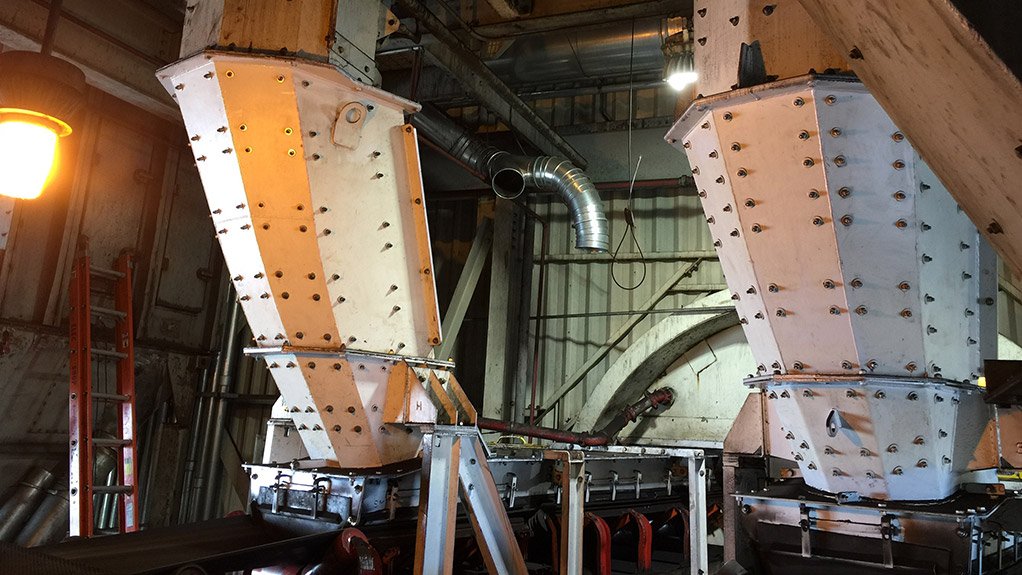

Although transfer points potentially contribute to some of the highest maintenance costs on a mine, engineers seldom view transfer systems as a critical element of the minerals processing system.

So, says Mark Baller, managing director of Weba Chute Systems, who maintains that transfer points — by the very nature of their application — should be viewed with the same level of importance as any other machinery in the minerals processing cycle.

“The uncontrolled discharge of bulk materials through conventional chutes has a history of escalated maintenance and replacement costs, not least of which can be attributed to excessive wear and other related problems,” Baller says. “All of this adds up to unnecessary expenditure and a headache for the engineers concerned.

“Numerous successful installations of Weba Chute Systems have proved that the correct use of our streamlined, scientific approach to the dynamics of bulk materials handling greatly reduces the problems associated with conventional transfer chutes and results in significant cost savings.”

Each Weba Chute System is custom designed for a specific application, considering factors such as belt width, belt speed, material sizes and shape and throughput. Baller says there are numerous advantages to be gained from this locally developed transfer system which, when introduced on a new project, achieves the optimum design configuration for the application with the best belt cleaning arrangement and optimum selection of belt type and size. In addition, spillage can be virtually eliminated.

Further benefits that apply equally to retrofitted Weba Chute Systems and new projects alike include up to 80% reduction in material degradation, greatly reduced levels of dust and noise, reduced production losses owing to fewer blockages, significantly reduced spillage and vastly improved safety levels.

Easy access is provided for inspection and maintenance purposes and the system does not require ongoing supervision, again representing a saving in manpower and related costs.

Baller says Weba Chute Systems should not be compared to conventional chute systems but rather seen as an improved alternative or “upgrade”, because they adopt a completely different and unique approach to control and handling of bulk materials. For instance, the system uses a “supertube” with a cascade scenario, where 95% of the material runs on material at all times.

“When one looks at this process in slow motion, it becomes apparent that the bottom layer of particles in the product stream move in a tumbling motion and do not slide down the chute,” he explains. “This results in significantly reduced wear and in many cases the lip remains completely covered by material and rarely needs replacement.”

This manner of controlling material movement is taken a step further by designing the internal angle of the transfer chute in such a way as to match the product discharge velocity with the belt speed, which either virtually eliminates or greatly reduces spillage.

Extensive experience and technical expertise, coupled with applications knowledge, has positioned Weba Chute Systems as the leader in its field. The Weba Chute System design is accomplished using sophisticated 3D computer software. Data received from the customer is always verified, and in many instances Weba Chute Systems’ highly skilled personnel are in a position to make cost saving recommendations.

The quality of the manufacturing process is strictly controlled by the company’s procedures which are in line with its ISO 9001 certification. Performance guarantees, set in accordance with operational and application parameters, are provided with all Weba Chute Systems.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation