Thyssenkrupp closes the loop in Africa’s sugar industry

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Thyssenkrupp Industrial Solutions South Africa combines local knowledge with global expertise to bring turnkey technology and equipment solutions that will promote the sustainability and profitability of the sugar industry in the Sub Sahara African region. The company offers market, feasibility and engineering studies as well as complete EPC (Engineering, Procurement & Construction).

Africa produces around 10 million tons of sugar per season and imports an additional two million tons to meet demand. South Africa, Swaziland and Mozambique are the three main players in the sugar industry in the Sub Saharan region.

Stretching across the provinces of Mpumalanga and KwaZulu-Natal with a small production in the Eastern Cape, South Africa’s R12 billion sugar industry consistently ranks in the top fifteen out of some 120 sugar producing countries worldwide, producing an average of 2,2 million tons of sugar per season. There are approximately 24 000 registered sugarcane growers in the country. Sugar is manufactured by around six milling companies with some fourteen sugar mills operating in the local cane-growing regions.

“But the full potential of the South African sugar industry can only be extracted if the numerous challenges facing this sector are addressed,” cautions Dayalan Padayachee, Senior Business Development Manager, thyssenkrupp Industrial Solutions South Africa. “This is an aging industry using old technologies which negatively impact plant reliability and throughput with subsequent cost implications. Additionally, as a result of the protracted drought, the industry is dealing with the worst cane production in a decade with subsequent drops in cane quality and volumes that adversely affect throughput.”

The rapid changes in environmental legislation over the past decade with strict laws regulating greenhouse emissions and waste water as well as the sugar tax on consumption present further challenges for the local sugar manufacturing industry. In addressing these challenges sugar manufacturers simply have to find ways to keep up throughput, maintain productivity and optimise in all areas while reducing input costs, according to Padayachee.

This is where thyssenkrupp, a highly qualified, quality-orientated company, steps in as the perfect sugar technology solutions partner.

“We have the technology and the equipment to build a complete plant, from feasibility studies right through to commissioning, but we also have the capabilities to identify specific areas where improvements to aging plants and optimisation of processes, systems and equipment are possible. Our approach is to look for ways how we can make our customers smarter throughout the production process with our main focusses here on energy conservation, water treatment, steam and plant optimisation as well as energy mass balance expertise.”

Thyssenkrupp‘s turnkey solutions will assist the local sugar industry to work smarter and improve profitability. Through the optimisation of processes and equipment end-users can improve efficiencies across the plant and conserve energy and water resources. New revenue streams can be generated by creating alternative markets through the production of by-products from recovered waste.

“One can also diversify excess sugar into biochemicals like Poly Lactic Acid, where Thyssenkrupp can support with its technology and execute the project on a turnkey basis,“ adds Padayachee. The water that is used during the crushing of the cane is used as heating vapours during the process. Water losses occur through molasses, filter cake, Bagasse, etc. According to Padayachee the balance of untreated water can be effectively treated and re-used for non-critical applications on the plant. “It is imperative that sugar producers start treating waste water to prevent harming the environment.

Additionally, treated water can be re-used, saving on the water bill as well as our country’s vulnerable water supply. We have the necessary skills and expertise to develop complete water treatment plants for sugar mills or add value to existing treatment facilities by providing for a polishing unit for example to assist mills in making the water suited for re-use.”

The Industrial Solutions business area of Thyssenkrupp is a leading partner for the engineering, construction and service of industrial plants and systems. Based on more than 200 years of experience we supply tailored, turnkey plants and components for customers in the chemical, fertilizer, cement, mining and steel industries. As a system partner to the automotive, aerospace and naval sectors we develop highly specialized solutions to meet the individual requirements of our customers. Around 19,000 employees at over 70 locations form a global network with a technology portfolio that guarantees maximum productivity and cost-efficiency.

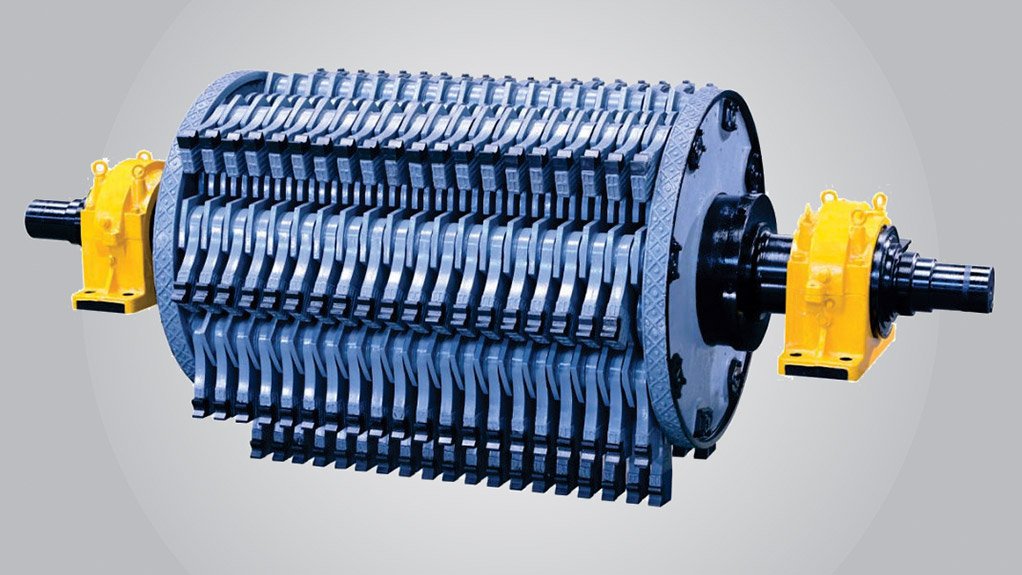

Its Centre of Excellence for sugar technology lies in Pimpri, Pune in India. Thyssenkrupp Industries India (tkII) has revolutionised the sugar industry over the past six decades with over 133 sugar plants built globally. The company’s advanced technology focusses on reliability, productivity and safety of products and equipment for each step in the sugar producing process: Cane handling (unloaders, feeder tables), cane preparation (choppers, levellers, fiberizors, shredders), cane milling (3/2-roller mills), process equipment (Falling Film Evaporators/Continuous Vacuum Pans, centrifugal machines), power generation plant (water cooled condensers, cooling towers), steam generation plant (boilers) and effluent treatment plant (sumps, screens). The equipment including boilers are manufactured by thyssenkrupp in India.

“We differentiate between the scopes of local knowledge and global expertise and specialists from India such as sugar technologists, process engineers and doctors in chemical engineering join the South African Thyssenkrupp team to deliver optimum solutions that will ensure a sustainable and prosperous future for Africa’s sugar industry,” concludes Padayachee.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation