Thermaspray’s Plasma coatings solve a sticky situation

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

The excellent release properties of Plasma non-stick coatings from Thermaspray render this surface coating technology ideal for a wide range of applications within industries such as food processing, printing and packaging, paper and pulp, tyre and rubber, and conveyor belt manufacturing.

These coatings, supplied by Thermaspray, in partnership with USA-based Plasma Coatings, combine the advantages of thermal spray (metal base) coatings with polymer top coatings to offer benefits of wear resistance, slip and traction. Applied to aluminium, steel, stainless steel, tool steel, copper, ceramics, synthetic materials, Plasma coatings assist industries in realising substantial cost savings through reduced maintenance and subsequent improved uptime and increased production output.

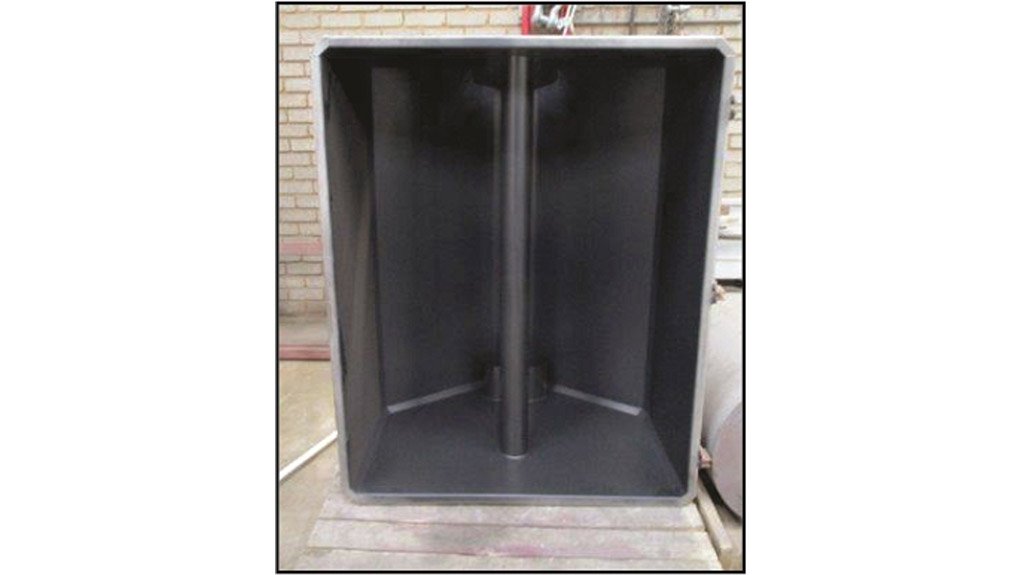

“Two years ago, we were approached by a bakery that was experiencing problems with dough sticking inside critical areas such as in the bins and dough pumps,” says Johan Squara, Sales Engineer at Thermaspray. The dough is fed by augers through a chute into the bread pans. The bakery which supplies bread to retail outlets around Gauteng, faced regular downtime and costly halts in the production line as the dough had to be removed from components and the surfaces had to be cleaned.

In addition, the on-time delivery of bread to retail stores was being compromised. “So they looked to us for a solution. We immediately suggested Plasma 14000 non-stick coating. The low coefficient of friction, excellent non-adhesive properties and long lasting nature of this coating makes it perfectly suited for this type of application.”

Thermaspray applied the Plasma 14000 coating to all areas that come into contact with the dough including augers, dough bins, dough pumps and baking pans.

The excellent release and water repelling (hydrophobic) properties of this coating ensures that the dough does not stick and allows it to easily slide off the surfaces of the coated components. Since the application of the coatings in 2016, the bakery, which runs 24/7, has reported no downtime as a result of dough sticking to surfaces.

Squara explains that there is a vast range of different Plasma coatings which are part of the PTFE (Polytetrafluoroethylene) family. “A good example of PTFE is the Teflon coating on frying pans. In addition to being food standard compliant, PTFE is chemically inert, ‘weatherable’, provides excellent electrical insulation and offers high temperature resistance. With the exception of medical plasters, absolutely nothing sticks to these plasma coatings.”

Thermaspray applies Plasma coatings to refurbished components meeting OEM standards and in some cases even exceeding OEM standards. This was the case with the bakery customer who was refurbishing an existing plant that operates older equipment.

Squara adds that Thermaspray also coat new components. “Although many OEM components are produced with non-stick coatings, the quality of these coatings does not match the Plasma offering. When these coatings eventually wear off, clients approach Thermaspray to recoat the components.

Thermaspray offers advice on the correct handling of the coated components during installation as well as best practice cleaning and maintenance procedures. If the coated components are looked after and well maintained, correct cleaning procedures are followed and sharp edges that can scratch the surface are avoided, Plasma coatings can substantially extend component life. “In fact,” adds Squara, “if treated correctly, treated components can last a life time.”

Plasma coatings are applied to components at Thermaspray’s facilities as the coatings, which consist of many different layers such as primers and bond coats, are applied with a special high-pressure spray gun. The components are then cured in ovens at temperatures of around 300° C. Squara mentions that there are various Plasma coating grades, each requiring different curing temperatures to ensure best results.

Other Plasma coatings in the range include traction and release coatings which are used for applications such a paper transfer. Although still presenting non-stick properties, the coated area is able to grip the paper on to the roll and once it has passed over the roll the paper is easily released. This coating is widely used in the tissue paper industry.

Testimony to the effectiveness of Plasma coatings is found in studies that show the use of a less expensive grade stainless steel with a Plasma coating outlasts an exotic and more expensive grade of stainless steel without a plasma coating.

Thermaspray has almost completed a successful Plasma coating trial at a conveyor belt manufacturer. Conveyor belts are made up of different layers of tightly pressed materials. The belts are manufactured under extreme pressures and after release the material was sticking to the bottom of the press plate, pulling the layers apart. Thermaspray replaced the original plastic coating on the plate which was proving to be inadequate with a Plasma coating and the customer is reporting extreme satisfaction with the results.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation