Thermaspray rolls out Laser Engraving Technology, boosting its comprehensive product portfolio

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

The recent introduction of laser engraving technology boosts Thermaspray’s comprehensive range of services and gives the coating technology specialist the capability to offer a complete end-to-end solution to the printing and packaging industry.

The company is a market leader in the refurbishment of worn Anilox rolls to extend their life cycle and also offers coatings of new rolls. “Historically, we prepared the rolls at Thermaspray and then sent them off to a company for laser engraving,” explains Thermaspray Managing Director, Dr. Jan Lourens. “Our relentless pursuit to constantly look for ways to improve customer service prompted us to offer an in-house laser engraving service.

In addition to acquiring a large top end laser engraving system, we have also appointed a laser engraving specialist, Dean Govender, who brings countless years of knowledge and experience to the table. His reputation as a specialist in this technology has earned him respect throughout the printing industry both locally as well as in other parts of Africa.”

Govender, who has attended training on laser engraving technology in the UK, and Germany, joined Thermaspray as Laser Engraving Manager on 1 August 2018. Govender explains that he has been a customer of Thermaspray for 18 years. “Thermaspray refurbishes Anilox rolls for the company where I was previously employed. I therefore understand Thermaspray and the team very well.”

The addition of laser engraving to Thermaspray’s manufacturing, refurbishing and coating capabilities gives the company the edge in offering a complete package all under one roof at its fully equipped facility in Olifantsfontein, Johannesburg. As a locally based company, Thermaspray adds tremendous value for its customers through much faster lead times and a more cost-effective solution compared to imported Anilox rolls.

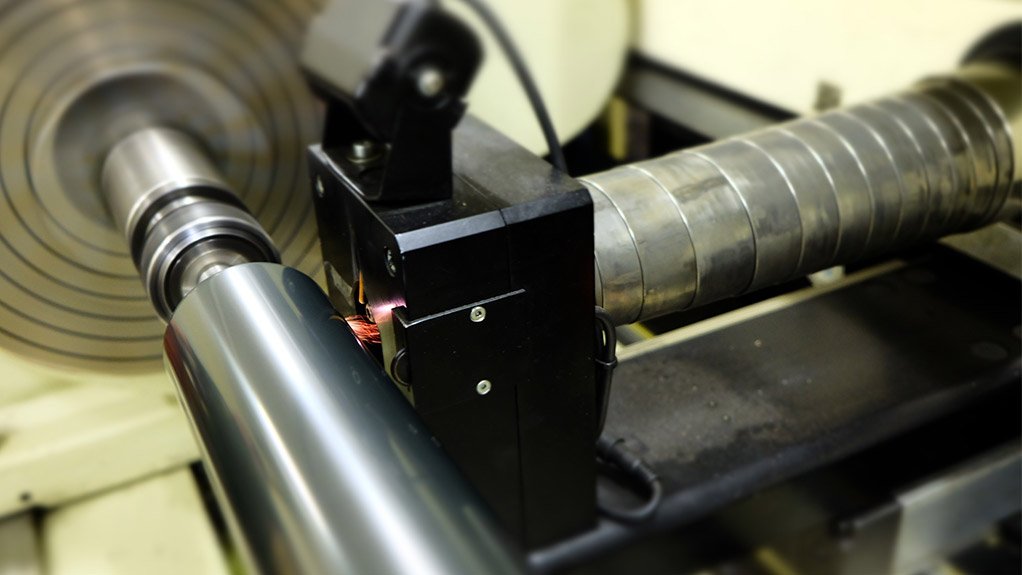

The German-manufactured, 600 Watts fibre optic laser has an engraving capacity from 100 to 1200 lines per inch. Ink in flexographic printing machines is transferred via laser engraved microscopic cells on to the Anilox roll or Anilox sleeve.

“Our system can perform laser engraving on a variety of materials including ceramic, polymer as well as ebonite rolls. We also offer glue applicator rolls which, using the same principle, transfers glue or starch instead of ink to the substrate,” confirms Govender. He adds that Thermaspray can also engrave sleeve Anilox rolls, explaining that the engraving is done on the sleeve. “Compared to Anilox rolls, sleeve Anilox rolls are lightweight and the latest technology available on new printing machines.”

The Laser Engraving machine can handle rolls between 50 – 500mm diameter and 100 – 3000mm in face length meeting customers’ varying requirements. The machine is equipped with multi-beam technology which speeds up the engraving process. But Govender is quick to point out that the time is determined by the cell count, volume and depth required.

The complete refurbishment process offered by Thermaspray on a used roll starts with inspection and a full analysis to determine how much wear has occurred and if the roll is suitable and cost effective for refurbishment. “If too much wear and scoring is evident, we will recommend the purchase of a new roll as a more cost-effective solution for our customer.”

Once the roll has been approved for refurbishment, it is prepared for pre-grinding, grit blasting, bond coat and ceramic top coat application is followed by precision grinding and polishing. The roll is then laser engraved and polished. A specially formulated sealer is applied to the finished roll to improve ink evacuation from the microscopic cells.

A Troika Anicam microscope is then used for quality control on the laser engraved roll to ensure the correct cell count, depth, and volume. According to Govender, quality control is critical to ensure consistent ink transfer across the roll face which is verified by the internationally used Troika Anicam. “All engraving data is captured and stored on the Troika Anicam software. We are able to provide certification reports to our customers on each individual roll, giving the customer proof of the engraving quality and specifications requested.”

As the PC-based Troika microscope is portable, Govender is able to inspect the quality of a roll directly on the printing press at a customer’s premises. Govender also conducts periodic inspections and roll analyses on site to determine when a roll will need refurbishment or cleaning. Predictive maintenance can deliver substantial cost savings for customers as it prevents poor print quality, critical failures and subsequent unplanned and costly downtime. The roll can be removed and sent for refurbishment during planned maintenance without affecting production.

Govender advises that regular roll inspection and maintenance is the smart thing to do as it is imperative that the correct roll is selected for a particular print job. Regular maintenance assists in extending roll lifecycle thereby minimising the need for frequent changing of rolls which is a time consuming task resulting in many hours of lost production.

The periodic maintenance reports generated by the Troika Anicam enable Govender to determine the approximate end of roll use. In this way the customer also gets the maximum use of the roll. In addition to advice and customer support, Govender also offers customer training on correct roll maintenance to extend the life cycle of the product and improve print quality.

Thermaspray’s complete value-added package includes roll collection and delivery. “The cost of a finished roll is high so we also ensure that the final product is carefully packed before leaving our premises,” he concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation