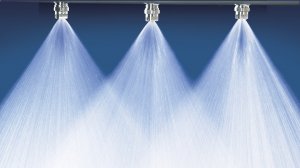

Spray Nozzles for Washing and Cleaning

The cleaning effectiveness of a spray nozzle, impact, or the total force of the spray as it hits a create conveyor or product, are the main criteria’s to evaluate spray pressure and impact. The true measure of cleaning effectiveness is impact per square cm. Maximizing the cleaning impact involves increasing both the mass of the spray and its velocity, which is accomplished by increasing flow rate in litres per minute, droplet size or bar.

Most people only think about spray pressure when it comes to impact, but increasing pressure can sometimes be counterproductive. High pressure produces smallerdroplets, which have less mass and velocity, and therefore less cleaning impact. As a general rule of thumb, increasing flow rate is much more effective than increasing pressure. Doubling the flow rate increases impact as much as 100%, while doubling pressure provides only 40% more impact.

The downside of increasing flow rate is increased water consumption, and one of the biggest operating cost today for food and beverage plants is water. At a time when sustainability, water conservation and lower operating costs are high priorities, it is possible to increase pressure and maintain cleaning effectiveness with premium, high-pressure nozzles.

SPRAY DISTANCE

Nozzle spray distance dramatically affects impact, and +-15 cm is the ideal distance to achieve the best performance from your spray nozzles. Increasing the nozzle distance just 15 cm from the product surface will decrease impact by 50%. Why? Because droplet velocity is reduced due to the frictional drag effects of the air and because the spray pattern is much larger. The same impact force over a larger area results in less impact pressure.

SPRAY ANGLE AND COVERAGE

Spray angle is the dispersion or width of the spray after it leaves the orifice. We are often asked if pressure affects the spray angle, and it definitely does. At high pressure, spray angles can widen significantly and produce low-impact misting of the spray as it fans out at the edges. Narrower spray angles have more cleaning force per square cm . Also, depending on the type of wash application, recommended angles vary.

HOW TO MAINTAIN SPRAY NOZZLE PERFORMANCE

1. INCORPORATE NOZZLE INSPECTION INTO YOUR REGULAR MAINTENANCE PROGRAM

Damaged spray nozzles waste water and chemicals, decrease cleaning coverage of the target area and increase workload on your pumps. With thousands of Rands of profits at stake, you’ll want to regularly monitor your spraying system to reveal potential problems. Some nozzle problems, like corrosion or caking, are easy to detect with a visual inspection, but a worn nozzle, the most common problem for a washing system, is almost impossible to detect with the human eye.

Watch for these clues to indicate spray nozzle problems:

Change in pump performance. If you have a positive displacement pump, check the pressure gauge for a drop in system pressure. If yes, the flow rate will remain constant, but spray velocity and impact will lessen. You may not be wasting water, but the quality of your wash will suffer. Some operators will adjust the unloader valve and use it as a regulator to increase pressure, but this can create high-pressure spikes and damage the pump

Increased chemical consumption. As the nozzles wear and pressure/impact decreases, some operators increase the concentration of the detergent – a much more costly solution than replacing nozzles

Deterioration of spray pattern. Inspect the spray pattern for uniformity. When nozzles are damaged, worn or clogged, the spray pattern is destroyed. Streaks develop and the spray will be heavier or lighter throughout the pattern. The result is inadequate or inconsistent coverage of the vehicle. Customers will experience uneven cleaning or drying, so you’ll want to make sure your nozzles are replaced before reaching this point.

Flow rate change. If you have a centrifugal pump, an increased flow rate indicates nozzle wear. System pressure will remain the same, enabling you to retain some quality in your wash, but your system will be highly inefficient, wasting costly water and chemicals

2. DECREASE SPRAYING PRESSURE

Where circumstances permit, decreasing the pressure will slow the liquid velocity through the orifice and reduce the wear and corrosion rate. You can take advantage of this tactic in the presoak stage where low-pressure, small-capacity nozzles are very effective because they provide streakless, full coverage. During presoak, it’s not the volume or spray impact that’s critical – it’s where you place the water and chemical.

USE CARE WHEN CLEANING SPRAY NOZZLES

Cleaning nozzles can often restore a defective spray, but it should be done with materials that are much softer than the nozzle orifice. Use toothbrushes, toothpicks or even compressed air. Never use wire brushes, pocket knives or welder’s tip cleaning rasps. It is easy to damage the critical orifice shape (or size) and end up with distorted spray patterns or excess flow. If you are faced with a stubborn clogging problem, soak the orifice in a non-corrosive cleaning chemical to soften or dissolve the substance.

ADD LINE STRAINERS OR USE SPRAY NOZZLES WITH BUILT-IN STRAINERS

When using fresh or recycled water, orifice deterioration and clogging are typical problems. Strainers or spray nozzles with built-in strainers are highly recommended in the presoak cycle. Line strainers not only extend the life of the nozzle but the pump as well. The strainer’s screen traps the dirt or unwanted material, and it should be made of stainless steel for strength and corrosion resistance. The screen is critical to the operation of the strainer, and an extra screen should be kept on hand for each strainer installed.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation