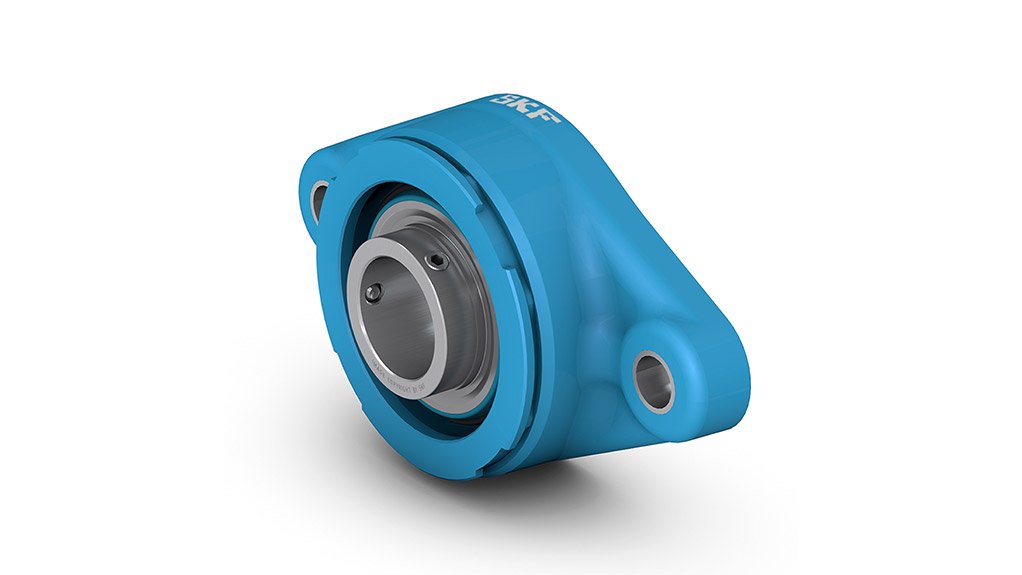

SKF sets new standard for hygienic design with ground-breaking Food Line ball bearing units

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Innovative ball bearing units expand hygienic-design possibilities, while delivering improved reliability, reduced maintenance costs, and increased sustainability for food and beverage companies.

With companies striving to perfect a proactive approach to food safety, SKF is launching the new Food Line ball bearing units – Blue Range, which extend a hygienic-design mentality to bearing unit components for food-processing equipment.

Since 2012, the food and beverage industry has seen a significant increase in units recalled—a 92,7% spike in FDA recalls and an 83,4% uptick in recalled products by the USDA.

- Meanwhile, bacterial contamination and undeclared allergens together represent 75% of the top FDA food recall causes based on units.

- With recalls on the rise, it’s no wonder that proactive food safety has become the foremost concern for food and beverage executives. While the broader approach to addressing food safety is top of the priorities, understanding about contamination risks at the component level has been lacking—along with a solution to address it.

“Companies have safety practices to protect their food product. These might include measures such as posted signs encouraging hand-washing or purchasing hygienically designed ‘food grade’ machines,” said Victoria van Camp, CTO & President, Innovation and Business Development, SKF. “The problem is, traditional relubrication, wash-downs, and dry cleaning of bearings can create hidden means by which contaminants thrive, such as airborne droplets, wastewater, or contaminated grease.”

Watch the video about how bacteria can enter the bearings and spread as the result of a cleaning regime.

“Eliminating these food-safety threats requires a different approach to hygienic design, and that’s what the Food Line ball bearings – Blue Range are designed to deliver – concludes Victoria.”

SKF has specifically developed its Food Line ball bearing units from a clean sheet of paper, component by component, to improve hygiene, performance, and compliance with food safety regulations.

Thanks to an innovative sealing system, high performing bearing grease, and complete seal-ability of the units where it’s needed, SKF Food Line ball bearings deliver outstanding performance benefits. Watch here what is behind the innovation.

This means OEMs can innovate the performance and hygienic design of their food processing equipment through bearing units that last longer, are relubrication-free and highly cleanable.

As a result, food and beverage processing companies can reduce unnecessary risks to food safety – Hygienic design of the bearing units reduces risk of bacteria build-up in hard-to-clean areas and minimizes the spread of bacteria during cleaning.

Furthermore, they can lead to an increased production uptime – Because bearing units do not require relubrication, there is no need to stop equipment for lubrication activities and less time is required for cleaning excess bearing grease—reducing downtime and maximizing production opportunities.

The Blue Range eliminates cost of relubrication and reduces bearing replacement frequency – With its relubrication-free capability and high-performance even in challenging food and beverage processing environments, companies can eliminate re-greasing material and labour costs, while reducing the frequency, thus cost of bearing replacements.

And, it reduces environmental waste – With less hot water needed for cleaning, grease in waste water and components that can be 100% recycled and energy recovered, companies can foster a preventive- versus disposal-oriented environmental.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation