Siemens showcases model of Mars robot at Future of Manufacturing Conference

COMOS WALKINSIDE SIMULATORThe COMOS simulator supports multiple avatars to test a team’s performance and communication on the plant

Photo by Duane Daws

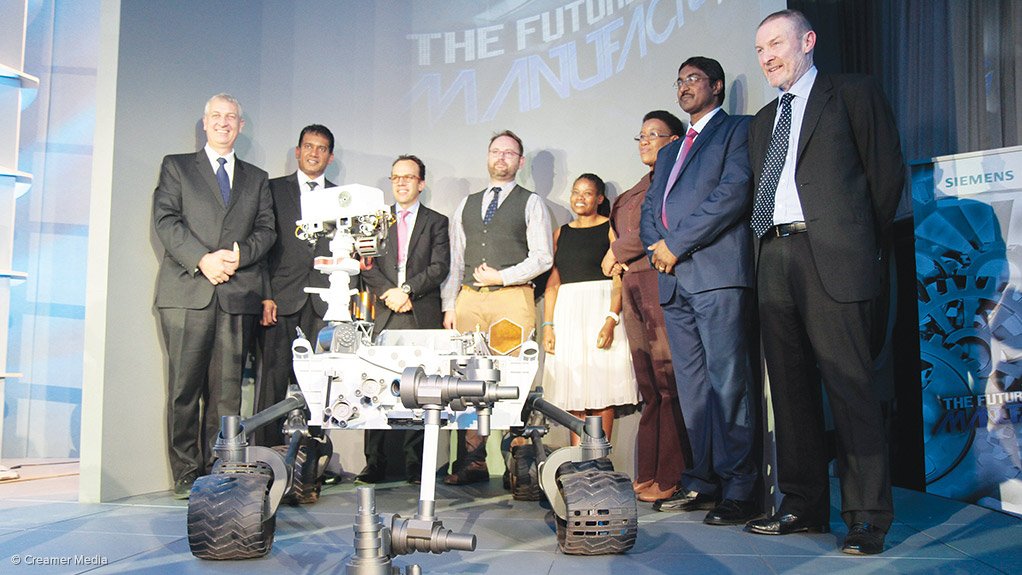

CURIOSITY MARS ROVER Siemens unveiled the Curiosity Mars Rover model at its Future of Manufacturing Conference

Multinational electronics company Siemens unveiled a working model of the Curiosity Mars Rover – which is the biggest robot to land on Mars – at its Future of Manufacturing Conference at the Birchwood Conference Centre in Boksburg last week.

The actual Curiosity Mars Rover landed on Mars in August 2012 after travelling over 560-million kilometres over nine months to get to its destination, where it has one shot at every single obstacle it tackles.

“Its construction had to be perfect and to take every risk into account. This includes the design of all 90 000 parts that work together inside the Curiosity Mars Rover, the complex entry and landing sequence on the Martian surface, and its survival in the planet’s harsh environment,” said Siemens communications and government affairs manager Keshin Govender.

He said that for this reason, the Curiosity Mars Rover model travels the world to explain how the complex robot was put together, tested and operates day-to-day – largely using Siemens’ engineering software.

“It’s unveiling here has marked its first visit to Africa,” he stated.

Govender pointed out that, given the little knowledge people have of the extensive manufacturing and technology that has gone into assembling the Rover, the conference presented an ideal opportunity to inform the industry of the Rover’s extensive simulation and testing processes on earth that make planetary exploration possible.

In partnership with US-based research and development centre the National Aeronautics and Space Administration (Nasa), Siemens used its computer-aided engineering software to test and simulate how the thousands of Rover parts would work together, and how much stress they could take from temperature, friction and pressure changes during the mission using what is called a kinetic simulation.

The Rover was put through the vacuum and extreme cold of deep space and also re-pressurised in the Martian atmosphere, where it experienced extreme wind speed, vibration, noise, G-forces and then scorching heat and freezing cold.

Govender highlighted that the Rover does not make a move on Mars without it being tested or simulated in some way.

This being the case, the identical replica of the Rover that is on Mars lives at Nasa’s Jet Propulsion Laboratory, where it is used to attempt recreated Martian obstacles before the Rover has a go at them on Mars.

The model unveiled at the conference is two-thirds of the size of the one on Mars and does not have power source and laser.

COMOS Walkinside ITS

During the conference, Siemens also showcased its COMOS Walkinside Immersive Training Simulator, which immerses operators in their plants.

“The Walkinside Simulator simulates real-life scenarios and supports multiple avatars to test the team’s performance and communication,” said Siemens engineer Ivan Stjepanovic at the conference.

He mentioned that this three-dimensional (3D) model may be enriched with all the details of an existing plant as the 3D objects are procedurally added to the virtual reality model in order to flag evacuation routes, emergency and firefighting equipment signs.

“By placing the 3D virtual plant on an operation, maintenance and engineering staff’s computer, plant operators can consolidate activities across a broad range of geographically dispersed user communities, focused on specific aspects of plant operation,” he explained.

The Walkinside Simulator allows users to ‘walk through’ the virtual plant to reach a plant area. They can then either jump to a specific element or extract data and documents, which are connected to the 3D model through smart links to external databases. Also, the users are able to update the data and documents relevant to an element or area.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation