Safety First With Durable Mentis Floor Grating

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

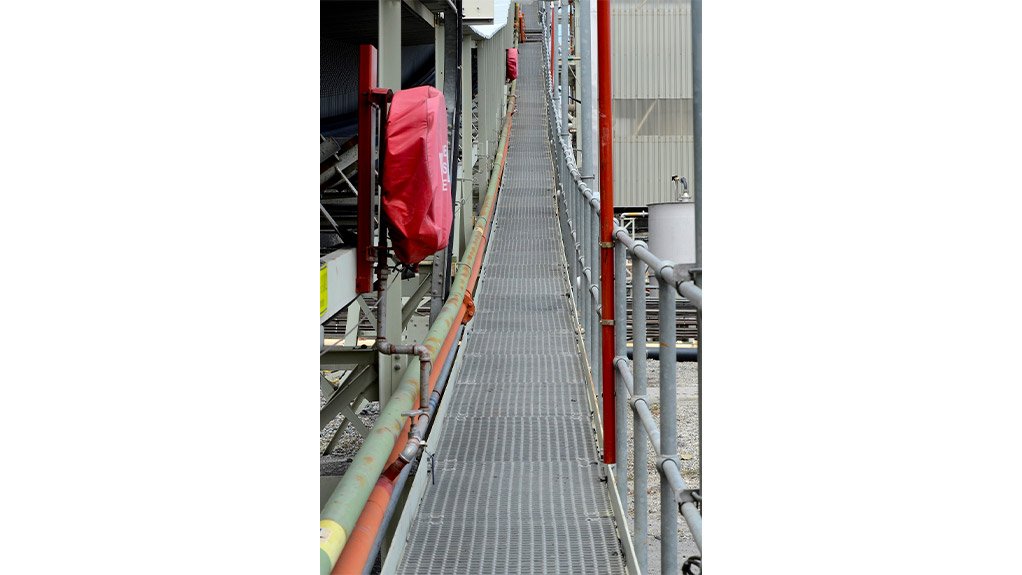

Liability claims from slips, trips and falls in the workplace can be financially debilitating and have an extremely negative impact on the reputation of a business. Considered the most frequent cause of injuries in the workplace, these incidents can result in serious downtime and even closure of facilities.

Floors, stairs and handrails are often cited as the cause of such accidents. In some incidents, injury is caused by factors beyond the reasonable control of the business owner. However, there is great wisdom in the adage ‘prevention is better than cure’.

Lance Quinlan, national technical sales consultant at Andrew Mentis, says that companies should consult floor grating specialists to ensure that their floor grating adheres to the required building regulations and occupational health and safety (OHS) standards.

He explains that unfortunately for the consumer, not all floor grating products on the market are of a suitably high standard. “An inferior quality product may well look identical to a reputed brand when viewed through the eyes of an unsuspecting customer. However, the real litmus test comes after the installation is completed and employees start walking on the floor grating.”

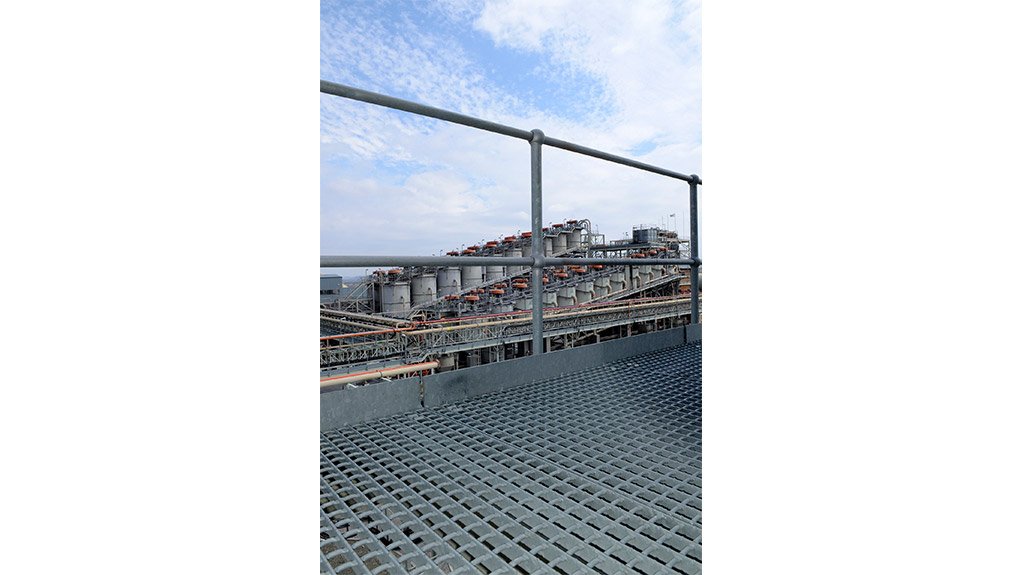

Quinlan cautions that customers should carefully research the claims made by the floor grating manufacturer. “Mentis floor grating is engineered to take specific loading which then ensures the optimum safety of the people walking on or working in those areas.

We initially meet with customers to determine their exact needs, then our processing department compiles the layouts for the required products according to the structural steel drawings supplied by the customer. A complete understanding of the load bearing capacity of grating is required to ensure that the correct floor grating product is selected for an application.”

All Mentis floor grating is manufactured in a world class facility at Elandsfontein, Johannesburg using a pressure locking system pioneered by the company.

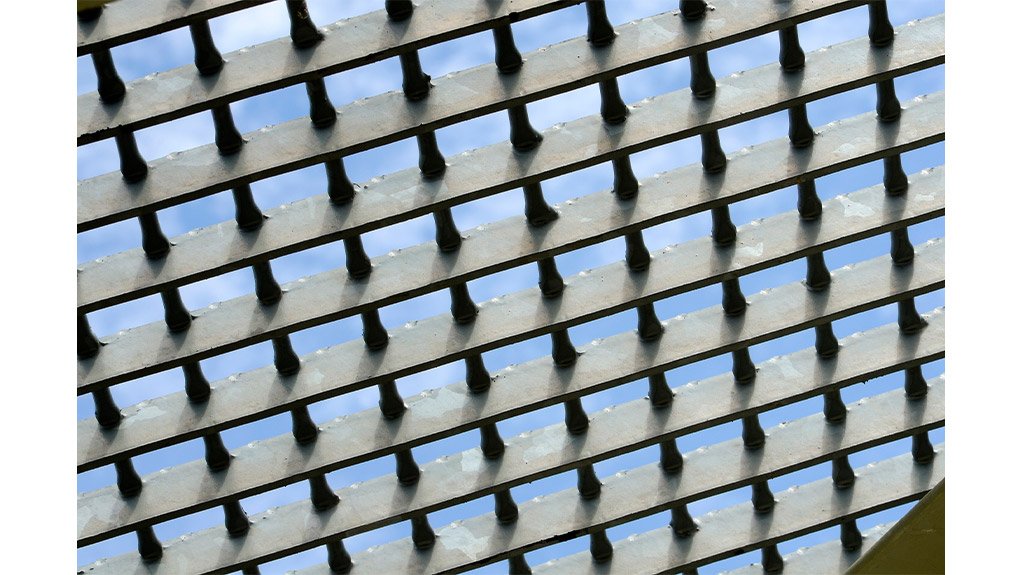

“Quality control is stringent during the manufacturing process to ensure that close tolerances are maintained and that the round transversal bar fits tightly through the pierced bearer bar on our floor grating products,” he says.

Mentis has two predominant floor grating products – Rectagrid RS40 40/40 and Rectagrid RS80 80/40. RS40 40/40 is a premium brand and is formed through a process of compressive pressure locking of bearer bars and transversals to form an exact pitch of 40 mm by 40 mm.

Rectagrid RS80 80/40 is identical to RS40 40/40 grating except that we omit every second bearer bar, giving an 80 mm pitch bearer bar with a 40 mm pitch transversal. This effectively reduces the RS80 80/40’s permissible load bearing capacity by 50%.

Quinlan emphasises that the most critical element is the load bearing capacity of the floor grating. “The best way to ensure the structural integrity of floor grating is to align yourself with a manufacturer who has designed and engineered the product to attain predetermined tolerances. Mentis is pedantic about the strict criteria set for its floor grating.”

Non-negotiable factors include the fact that the transversals must be positively and permanently locked to the bearer bars. “In addition, there must be no cracks or crevices at intersections which could harbour corrosion. The locking method at the intersections should be designed to use the full depth of the bearer bar when calculating loads.

Finally, the grating panels should be flat, square and untwisted. Safety in the workplace simply cannot be compromised,” he concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation