Rittal announces investment in Perforex machine, set to benefit local market

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

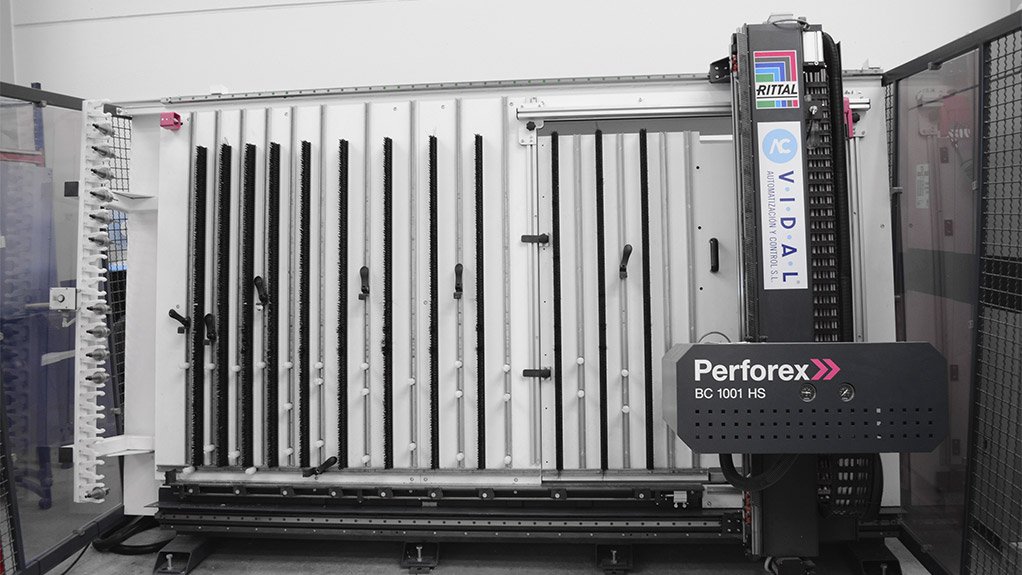

Earlier this month, Rittal South Africa – a leading systems provider for enclosures, power distribution, climate control, IT infrastructure and software & services – announced its acquisition of a BC 1007 HS Perforex machine – one of only two in the country. In collaboration with sister company, EPLAN, Rittal has successfully integrated the machine at its local headquarters in Edenvale, Johannesburg.

Used to manufacture enclosures using fully automated, high-speed, precision machining of mounting plates, doors, side panels, etc., the Perforex enables Rittal to deliver customised and precisely machined panels to customers within 24 to 48 hours. “This machine enables us to reduce lead times significantly. Up until now, local customers have waited anywhere between 14 to 18 days to receive finished panels,” explains Adrian Buddingh, Managing Director, Rittal South Africa.

“This Perforex machine allows us to machine commonly used materials – including steel, aluminium, plastic and copper – cost-effectively, with significant enhancement to precision,” comments Buddingh. “In addition, the machine will enable us to handle a higher capacity of machining orders, faster”.

A complete solution that reduces costs and lead times

Aside from the reduced lead time for the delivery of panels, the Perforex machine enables Rittal to supply complete panels to customers – without the additional costs associated with transporting, tooling and finishing of panels. “For customers requiring customised panels, the Perforex delivers not only precision-finished items, but saves them the added costs and time delays normally associated with customisation,” adds Buddingh.

News of Rittal’s acquisition of the Perforex has been well-received by customers. “Our VIP customers were invited to view the machine in action, and their feedback was extremely positive,” says Jason Osner, National Sales Manager, Rittal South Africa. “The collaborative approach we took with our sister company, EPLAN, is a great case study in the integrated value chain that EPLAN and Rittal offer the market”.

The Perforex: A cut above the rest

A number of specialised features make the BC 1007 HS Perforex ideal for use.

The systems user interface features an intuitive programming system which support remote maintenance activities. The local team received comprehensive training on the system, delivered in-person by Noah Kirschniok, a product specialist from the company’s head office in Germany.

A fixed tool magazine on the left-hand side of the machine, with 18 magazine slots for the machines, makes automated tool changes swift and easy. “The speed, feed rate, upstream tools and lubrication interval are preset for various materials for each tool. These no longer need to be included during programming,” explains Osner.

The machine’s pneumatic clamping device allows for easy clamping of cases and enclosure panels such as doors, side panels and mounting plates, using clamping fingers and membrane clamps. The machine’s brush strips and special milling cutters ensure fast, low-vibration milling. This promotes not only a higher feed rate, but also enables extended tool life.

The patented plate design reduces vibrations in the material, extending the service life of the tools. The machine’s powerful 7.5 kW spindle drive offers 18,000 rpm operation for drilling, thread-tapping, thread-forming, circular thread milling and engraving, and milling cut-outs in all contours. Racks and pinions are automatically lubricated for minimal maintenance.

Anticipating market take-up

Based on initial customer feedback, and the current needs of the local market, Osner and Buddingh anticipate that the Perforex solution will be in high demand. “In a competitive global marketplace, our customers understand that precision, speed and quality are all key. The Perforex delivers all three. We look forward to introducing the Perforex to a growing customer base,” concludes Osner.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation