Refraline – turning original ideas into world-class products

Johannesburg-based refractory and corrosion engineering solutions provider Refraline has expanded its services to include the full scope of original-equipment manufacturing, including refractory lining design, and material research and development. Refraline CEO Manfred Rösch tells Engineering News & Mining Weekly that with the company’s customer-focused approach, a specific refractory problem is analysed with the aim of facilitating cost reduction.

Thermal energy process industry’s innovative partner of choice

Johannesburg-based refractory and corrosion engineering solutions provider Refraline has expanded its services to include the full scope of original-equipment manufacturing (OEM) including refractory lining design, and material research and development (R&D).

Refraline has developed a range of monolithic refractory materials, which has undergone significant testing. The company’s R&D facility enables it to develop customer-specific refractory materials and set new trends.

Refraline CEO Manfred Rösch tells Engineering News & Mining Weekly

that with the company’s customer-focused approach, a specific refractory problem is analysed with the aim of facilitating cost reduction.

“Through our in-house R&D depart-ment, we have been working on improving the properties of refractory technologies to eliminate the need for importing these products,” he explains.

The company produces a full range of refractory monolithics including con-ventional castables; medium, low, and ultra-low cement castables; gel-bonded castables, and taphole clays (THC).

“There are perhaps a handful of com-panies in the world that match the properties of our castable materials, making Refraline a market leader,” he says.

Prioritising Health & Safety

As a company that prides itself on being customer-centric, the health and safety culture is a fundamental value throughout the group.

Rösch says some customers expressed a concern that current THCs use a tar and resin bonded system which has highly toxic carcinogenic properties.

Refraline engineered a non-toxic THC that eliminates these toxins, ensuring a safer working environment for refractory workers.

The company then invested in a pro-duction line at its factory in Meadowdale, in Gauteng, and Malaysia to supply the smelting industry with its ground-breaking non-toxic THC, a low-temperature binding system that replaces the use of toxic tar and resin which has been used in the smelting industry for decades.

“We have solved an environmental problem where these toxins are no longer released into the workspace, and we have eliminated the health risk of the effect of carcinogenic toxins on employees. Our THC fulfils all operational requirements and we have gained a significant market share through this innovation, owing to it being more cost-effective for the end-user,” he explains.

THC is used to plug the taphole of a smelting furnace in a safe way and then retain the metal that is building up until the furnace is ready to tap for metal again. The heat in the furnace lining sets off the bonding system to ensure sufficient strength in the THC, holding the metal trapped behind it.

Industrial trials and emissions testing proved that Refraline’s THC eliminated all toxic substances emitted by traditional THCs.

Other innovations include its nano-gel technology used for refractory materials, improving its properties. The product, known as Refbond, reduces the cost of ownership of refractory-lined vessels by introducing the endless lining concept.

A stand-out advantage is the ultra-fine nanoparticles that act as anchors into the microporosity of existing refractory linings, bonding the new and the existing lining together.

Since refractory linings are consumables, they are subject to wear under extreme conditions. This requires that linings be replaced or repaired periodically, but since traditional repair methods cannot bond well, these repairs are mostly unsuccessful.

Gel-bonded linings eliminate this problem, as worn linings can now be repaired with a refractory castable that has the same properties as the original lining.

“This cost-effective endless lining system eliminates the cost and time to demolish a worn lining and reduces the amount of refractory castable used, resulting in a fast and economical repair that brings the lining up to original design specification,” Rösch emphasised.

New Project Pipeline

Refraline prides itself on taking a holistic view when embarking on new projects.

“We cannot isolate the installation, the production or the materials when embarking on a new project — we need to look at it holistically,” notes Rösch.

This, he says, begins with an idea.

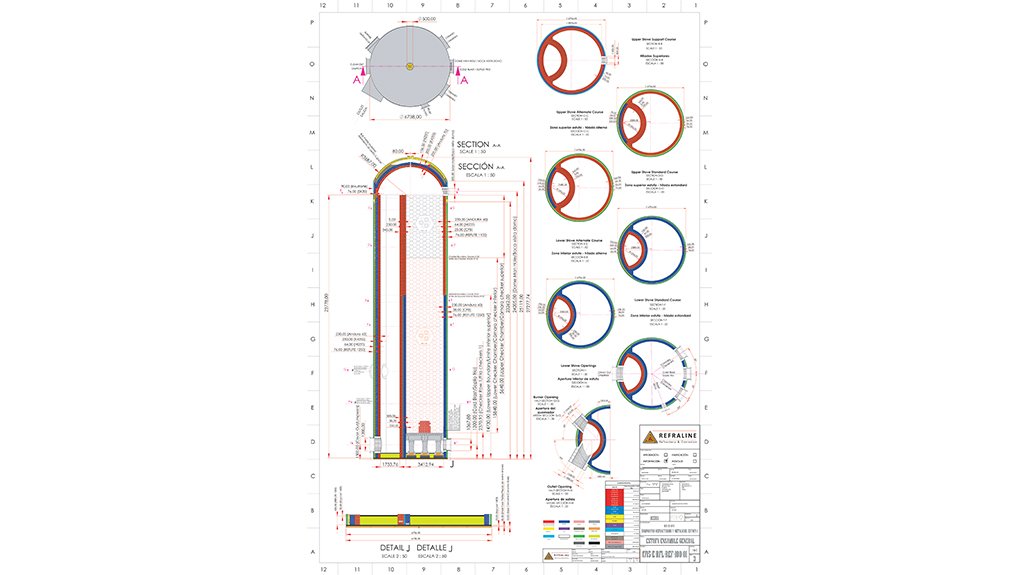

This holistic view has been employed on a $2.5-million hot blast stove project in South America. The 50-year-old design, from 1972, was updated using new design concepts to allow for better performance and an increased lifetime.

The project comprises of 110 different refractory shapes, with some of the materials sourced from Refraline’s South African production facility and some imported from international suppliers.

This design has catapulted Refraline onto a new design capability stage.

“We are not just installers and manufacturers anymore — we are now an OEM technology provider for the thermal energy processing industry,” says Rösch.

As an expert in the field of materials technology and installations, Refraline’s approach offers something different to its customers than a traditional OEM.

“The working of a stove hasn’t really changed over the years, but technology has. Refraline is excited to assist customers in challenging their existing practices so that hidden benefits can be found.”

In a greenfield antimony project in Oman the company applied its holistic refractory expertise successfully for the benefit of the customer, to a scale and complexity never done before.

“Our R&D and design capabilities ensure that we can expand our project capacity and expertise. The most rewarding part of our job is our capacity to invent, and then see it being built,” he concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation