Recent technology modernisations within the South African context

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

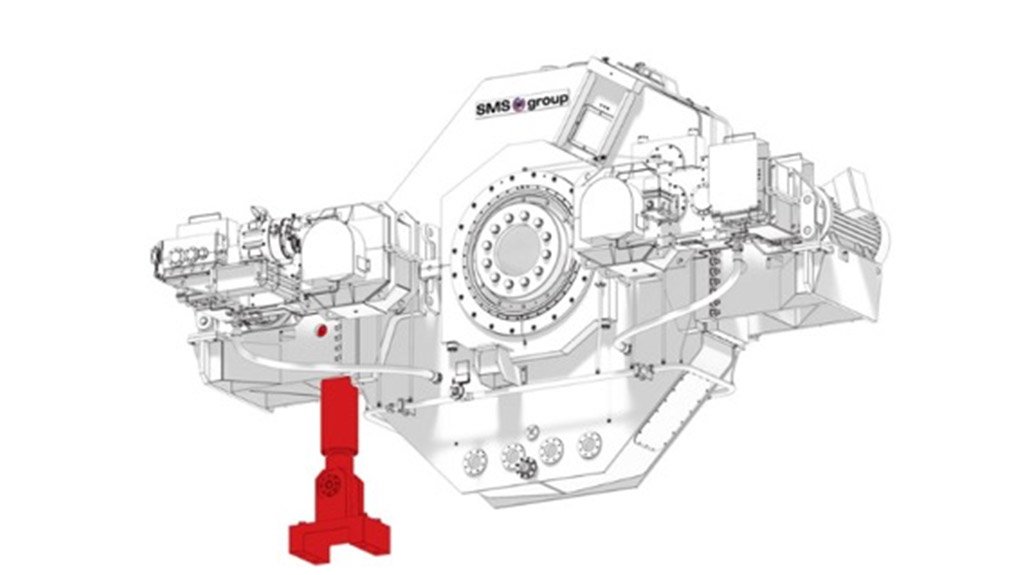

SMS group has successfully supplied and installed a Torque Retainer System for the two 100-ton AOD Converters at Columbus Stainless (Pty) Ltd. in Middelburg, South Africa. Columbus Stainless is part of the Acerinox group of companies and is the only stainless steel plant on the African continent.

The customer awarded the final acceptance certificate following a very short revamp and successful re-commissioning. The aim of the revamp – to reduce the force on the gearbox during the AOD converter refining process that had been causing uncontrolled vibrations and damage to the bull gear, bearings and foundation of the converter drive – has been fully achieved.

SMS group supplied the Torque Retainer as a compact electro-hydraulic unit. Engineering and erection supervision were also included in the scope of supply. The revamp took place during a scheduled shutdown. The Converters resumed operation and were running at full production capacity at an interval of two days. The first Converter reached the guaranteed values three days after hot commissioning, while the second Converter had already attained the guaranteed values after only one day. Both, cold and hot commissioning were completed jointly with the Customer. The good cooperation and high commitment of the teams from Columbus and SMS group made this success possible.

2. Air-Knives

DUMA-BANDZINK (a SMS group company), in cooperation with SMS group, is supplying three new Air-knife systems for existing Galvanizing Lines in South Africa. The objective, to increase surface quality and to drastically reduce zinc consumption. The hot-dip galvanized (GI) sheets manufactured on these galvanizing lines are mostly supplied to South Africa and other African countries.

The three Air-knife systems are prepared for an upgrade to become the integrated solution with EMG’s eMASS®. EMG eMASS® is a turnkey system for stabilising high-speed ferromagnetic steel strip material based on electro magnets. The main area of application is to optimise and economise the use of the metal coating at the blow-off nozzle of a hot-dip galvanising line for zinc coating, GALVALUME®* and aluminisation processes.

The EMG eMASS® system is installed above the air knife and as close as possible to the air knife lip, which wipes off the liquid metallic layer. Based on the experience of more than 50 installations around the world, EMG designs the integration of eMASS® systems for the air knife area in an optimal and customer-specific manner.

In summary the DUMA Air-knife offers the following advantages:

- The robust design in conjunction with the most sophisticated technology that provides good value for money.

- The low deviation of pre-set values that becomes exceptionally economic for thicker zinc layers due to the enormous amount of saved zinc that may sum up to several grams per square meter and thus several hundred thousand of Euros per year in savings.

3. Gears – AMSA Saldanha

SMS group drive technology features above all rolling mill drive trains, converter tilt drives, as well as shear and coiler drives. Paramount here are power upgrades, plus improving the reliability of existing plants.

Today's trend of rolling high-strength materials requires higher torque capabilities at the drive train. That's where SMS group comes in with its drive technology to meet this demand.

It all starts with systematic investigation of drive trains. Applying our rolling process know-how, we identify measures to improve your equipment. Furthermore, comprehensive world-wide service including gear inspections, repairs, and emergency response is part of our corporate philosophy. Wherever existing spare parts fail to make the grade, we refine them to the state of the art.

Most gears in the metallurgical industry run with quenched and tempered output gears. However, gears made from this type of steel come with a significantly lower wear resistance than the much harder case-hardened variety. This is where SMS group's fatigue-resistant output gears make all the difference. Why? Because they are the most reliable solution for high-performance work roll drives.

What's so special about the SMS group case-hardening process for large gear wheels is that it boosts the torque capacity of new as well as existing gearboxes.

The Gears at the Hot Strip Mill in ArcelorMittal Saldanha are reaching the end of its campaign life span. The Plant engaged SMS group with respect to an advanced gear design. This gear design offers the possibility to increase the torque capacity of new gearboxes as well as existing gearboxes. The new Gear Sets can transmit more than 30% higher torques with the same outer dimensions. Several other customers have already exchanged their existing mill pinions by new gear sets with the advanced gear design. The first phase of Gears for the Plant’s Roughing and Finishing Mills were supplied in May 2017 and have satisfied the most stringent quality control measures. These include ultrasonic tests for all blanks, rims, shafts and all weld seams up to each single tooth together with 100% automatic grinding burn detection on the Gear Measuring Machine (Barkhausen Noise Analysis).

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation