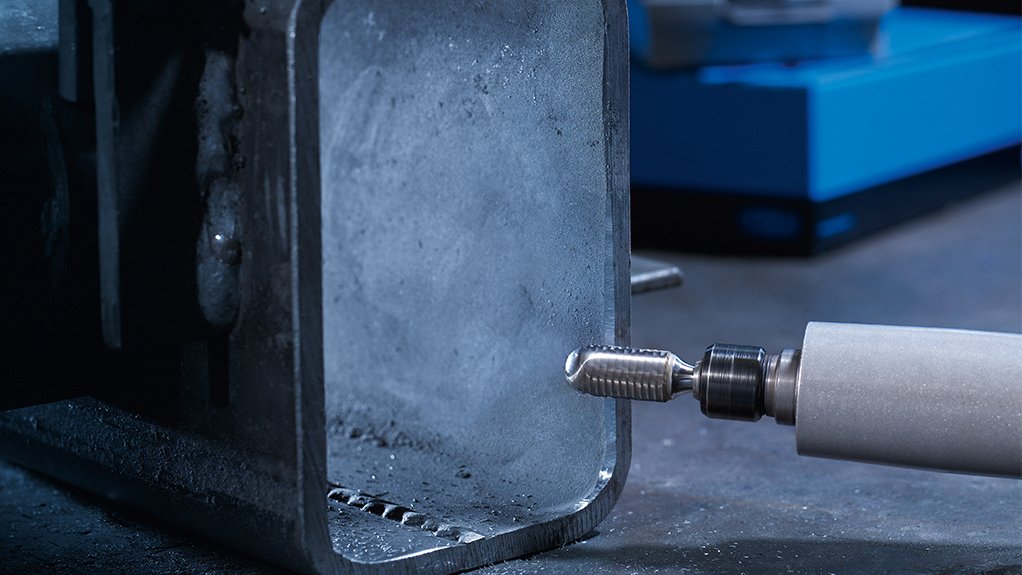

Precision to the point with tungsten carbide burrs

When your application requires a precision cutting or milling process, turn to Grinding Techniques for high quality tungsten carbide burrs that will effortlessly shape, cut, grind, or remove burrs, sharp edges and excess material from your workpiece, castings, and forgings. Tungsten carbide burrs, also known as rotary files or die grinder bits, are considered precision tools and are commonly used in industries such as foundries, shipbuilding, aviation, automotive and metal fabrication shops. Due to their versatility, they are suitable for a variety of materials ranging from steel, stainless steels, aluminium, cast iron, plastics and wood.

With so many cut styles available in the market, it is important to choose the correct configuration for your specific application. Some of the configurations available include single cut, chip-breaker and the premium double cut burr.

A single cut burr typically has a single flute which causes the chip removed from the material to be sharp and long. This burr is known as a general-purpose design and is well suited for cast iron, steel, and other ferrous metals.

The chip-breaker cut makes use of the same single flute design, but with the inclusion of a spiral cut in the opposite direction to break the single flute and produce smaller swarf pieces and improve operator control during application.

Double cut burrs on the other hand have flutes cut in a cross-cut direction which enables a double cut during every rotation of the burr. This not only minimises the time it takes to remove the excess material, but also ensures that the swarf being removed is cut into very small pieces. The Andor Speedline range of double cut burrs also has the added advantage of ensuring the swarf removed is blunt and will not penetrate the skin, further supporting operator safety. The double cut is known for being the most versatile of the range.

Due to the smaller swarf being produced, the double cut burrs also produce a smoother finish compared with that of a single cut or chip-breaker cut burr.

Along with the different configurations, one also needs to choose the correct shape for your application.

The shape will depend on the profile or cut that will be required on the workpiece. Ball shaped burrs are perfect to create concave cuts or to hollow out an area. When you need to round off edges, a tree-shaped burr will be best suited. Parts where a V-cut is required or where the rear side needs to be chamfered will need a burr with an inverted cone.

When using a tungsten carbide burr, it is important to remember that, due to the flute design, they are manufactured to be used with die grinders or pneumatic rotary tools and not with normal drills. Their optimal performance speed rating ranges from 17 898 RPM to 39 773 RPM (dependent on the size of the head of the burr) if used in a drilling machine running at around 2 000 RPM to 3 000 RPM, which is significantly less than a die grinder or pneumatic rotary tool, cutting effectiveness will be hindered, the burr could chip and clog up, and excess heat will be generated that could lead to the premature failing of the shank of the burr potentially causing detachment from the shank.

Always ensure your burr runs at optimal speed. A general guideline to remember is that the smaller the dimension of the burr, the faster the optimal speed of the burr, and the bigger the dimension of the burr, the slower the burr needs to run at.

When using a tungsten carbide burr it is important to allow the tool to do the cutting work and not to apply too much pressure, as excessive force will cause the burr’s cutting edge of the flutes to chip away or blunt too quickly which will instantly reduce the longevity of the burr.

To avoid the burr digging and grabbing into the material, it is important to move it around during application and not to hold it in one section for too long.

Due to the extreme hardness of tungsten carbide burrs, they can be used on more demanding jobs tolerating higher temperatures than that of HSS burrs, which are prone to soften under higher working temperatures.

Whatever your requirement when it comes to precision tools, we have a customised solution for your application.

Contact our business development team today for a customised solution for your application

T: +27 11 271 6400 |E: info@grindtech.com | W: www.grindtech.com

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation