Petra plans $300m notes issue to fund R1.65bn overhaul of 68-yr-old Cullinan plant

JOHANNESBURG (miningweekly.com) – Jersey-headquartered Petra Diamonds plans to launch a $300-million notes issue and increase its senior lender debt facilities to fund the construction of a R1.65-billion processing plant at the Cullinan mine, in South Africa, by the end of 2017.

The group outlined on Friday that it intended to offer $300-million in aggregate principal amount of senior secured notes, which would be issued by its US subsidiary.

Proceeds from the notes would be used to settle certain existing debt and, together with future drawdowns from the group's debt facilities, to fund the construction of the processing plant at Cullinan, as well as for general corporate purposes and to pay fees and expenses associated with the notes.

Moreover, Petra's lender group, comprising Absa, FirstRand and the International Finance Corporation, had agreed, in principle, and subject to the closing of the notes, to increase the group's debt facilities by $81.6-million to $302.4-million, along with certain amended availability and repayment terms.

“The notes, along with the increase in lender group debt facilities, will diversify Petra's sources of funding, providing the group with additional financial flexibility as it pursues its stated growth strategy,” the company said in a statement.

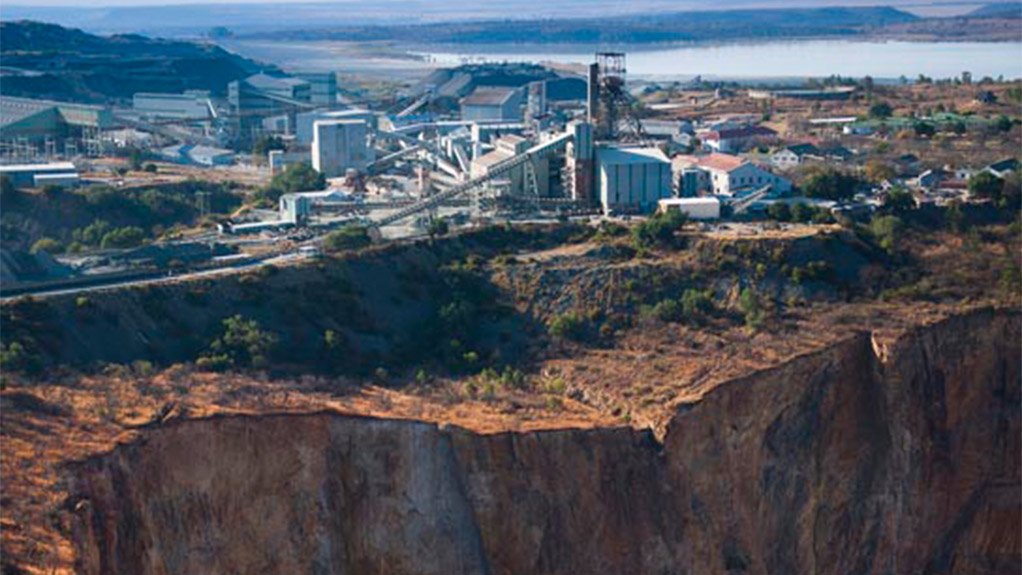

Petra outlined that the existing Cullinan plant had been commissioned in 1947 and had since undergone various refurbishments over the years.

Owing to its age and operational complexity, it was expensive to maintain and costly to operate, requiring significant stay-in-business capital expenditure.

“The plant is also based on old crushing technology, which we believe does not offer the best potential for optimal diamond recoveries,” Petra maintained.

The diamond producer explained that it was planning the construction of a modern, fit-for-purpose processing plant at Cullinan with a throughput capacity of six-million tons a year.

The new plant was expected to improve the recovery of the full spectrum of diamonds –thereby increasing the volume of stones recovered, as well as better protecting large stones from breakage – and improve the efficiency of the material flow, thereby significantly lowering operating costs.

It would incorporate an autogenous mill, which Petra believed offered a gentler recovery process that broke down ore through attrition rather than crushing, thereby better protecting the large, high-value stones for which the Cullinan mine was known.

High-pressure grinding roll technology, which was considered a gentler liberation technique incorporating interparticle crushing that moved away from high-impact cone crushing, would also be included in the design.

X-ray fluorescence technology would, meanwhile, replace the conventional dense media separation plants, enabling the plant to treat coarser material over 12 mm in diameter.

“Cullinan is known to consistently produce large, high-value diamonds, including the 3 106 ct Cullinan diamond – the largest gem diamond ever recovered. At the time the mine was taken over by Petra it had produced one-quarter of all the world's diamonds greater than 400 ct.

“The new plant is expected to reduce large stone breakage with a resultant positive impact on recoveries and sales revenues,” the diamond producer noted.

In addition to the benefits to large stone recoveries, Petra believed the improved diamond liberation technologies were expected to lead to an improvement in the currently guided overall grade achieved at Cullinan.

The new plant would also reduce the processing footprint at Cullinan from 26 ha to 5 ha, with the associated reduction of engineering infrastructure deployed, including an expected reduction in the number of conveyor belts used from 151 to 22.

“Operating efficiencies and security improvements will be driven through increased automation, reduced tonnes in circulation and improved energy efficiencies, with an expected improvement in energy efficiency.

“Based on these efficiencies, the company will target overall direct cash cost savings of up to R15/t treated,” it stated.

The bulk of the project related work would be executed by MDM Engineering and the company did not expect there to be any impact on current day-to-day operations or throughput at Cullinan while the new plant was being built.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation