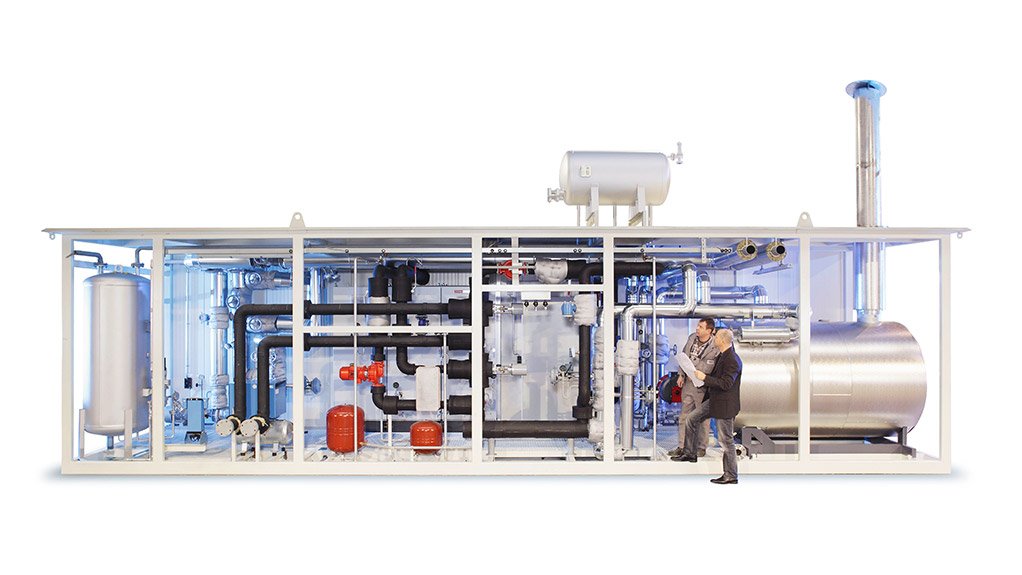

Packaged heating system to reduce heavy fuel oil’s viscosity

VISCOSITY REDUCTION The high-temperature temper packaged heating system will be used to heat up the heavy fuel oil from 20 ˚C to 80 ˚C

and gas specialised equipment supplier Energas Technologies this month commissioned a packaged heating system for a local oil storage facility upgrade – the first of this type of installation for the oil storage facility.

Heavy fuel oil (HFO) is stored in large tanks at the local oil storage facility in northern Gauteng. As HFO has a high viscosity at ambient temperature, the oil needs to be heated to reduce the viscosity before it is loaded into tanker trucks.

“To address this need, Energas Technologies supplied a high temperature temper (HTT) packaged heating system, which will be used to heat up this HFO from 20 °C to 80 °C,” notes Energas Technologies product engineer Laetitia Botha.

The system, produced by Germany-based manufacturer HTT, comprises a gas-fired oil heater and thermal oil circulation system, as well as a control system and heat exchangers.

Botha further explains that the packaged unit is fully automated and fitted with local control systems, process control and instrumentation equipment. The control system is interfaced with the local RTU programmable logic computer, which means that making changes on the heater units remotely is possible.

Advantages of the HTT packaged heating system include increased productivity, owing to higher process temperatures, lower investment costs as a result of lower operating pressure of the thermal oil, when compared with steam, as well as lower operating and personnel costs, as the operation does not need to be attended.

Botha adds that, with regard to maintenance, an oil sample analysis of the HFO only needs to be taken once a year to determine the efficiency of the system.

Moreover, the modern three-pass design of the heating system’s burner brings state-of-the-art heater technology to the project, Botha says.

She explains that the system works with the heat transfer medium, which flows through two concentric coiled tubes in the heater that are connected in series, while the hot flue gases are guided by means of defined annular gaps in the counterflow.

In contrast with the conventional type of construction, the flue gases are recirculated twice inside the apparatus; in the second and third passes, their energy is delivered to the transfer medium by means of convection.

Apart from the extremely compact design of the package, another advantage of the HTT principle is that it dispenses with a fireclay-lined furnace.

“This permits heat storage masses to be reduced to a minimum. “ This breakthrough eliminates the thermal overloading of the heat transfer medium that was previously unavoidable in the event of an unscheduled shutdown, and is an important step towards maintenance-free heaters,” Botha says.

The system is operated either with natural gas or with liquid petroleum gas.

Botha adds that the complete heat transfer facility was installed outdoors, so all the components had to be weather-resistant and winterised.

This meant that all the equipment had to be fitted with a rainproof weather jacket to guard against inclement weather, as well as high quality corrosion protection.

Investing in Energy

Botha highlights that, while energy has always been affordable in South Africa compared with European countries, times are changing, with the industry having to consider investments that are more energy efficient in the long run.

“We often find that projects are driven by initial capital investment costs or savings and do not always take the long-term benefits of paying for quality into account,” she says.

Botha, however, suggests that paying a premium upfront for better technology with higher efficiency could save millions in running costs throughout a plant’s lifetime. Moreover, return on investment can often be achieved within 12 to 24 months.

“This is what Energas Tech-nologies, with the world-class product support of HTT, aims to achieve with the HFO depot upgrade. “As a leading supplier to this market, no one else knows the value of energy quite like we do. “And we know how to save it,” Botha says.

Energas Technologies also supplied natural gas equipment, including gas regulators, flow meters, pipeline ball valves and filters to the oil storage facility.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation