New technology extends the life of long-travel energy chains

New glide pads and roller chain links have been developed to extend the life of igus E4.1 energy chains

Polymer energy chains are used in ports, logistics centres, mines and other industries to safely guide cables and hoses to reduce damage and abrasion, as well as to help provide an orderly and safe environment around equipment.

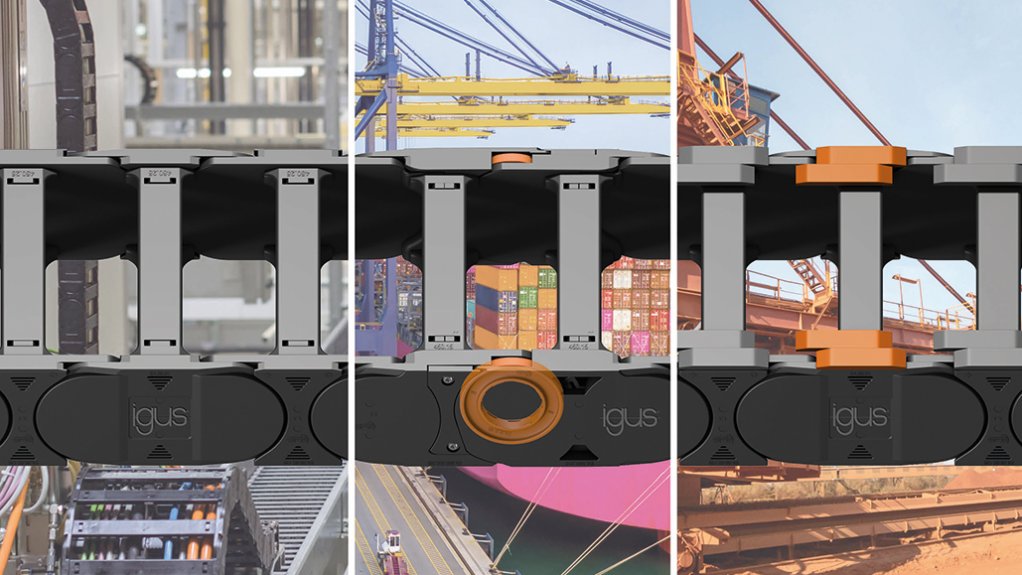

Advanced new glide pads and roller chain links for quick retrofitting have been developed to help extend the service life of chains quickly and cost effectively, especially where they are used in abrasive environments, at very high speeds or where extreme travel lengths are involved.

Polymer energy chain producer igus says more than 25 000 of its energy chains move over long distances every year and are used for indoor and outdoor cranes, mobile cranes, storage retrieval units, computer numerical controlled applications, tripper cars, linear robots, ship-to-shore cranes, storage and retrieval units or linear robots. The igus modular E4.1 energy chain system is used in all these areas of application.

“The energy supply system has an undercut design and thus a high torsional rigidity. It is quiet and variable in heights and widths. In 90% of gliding applications, the E4.1 is the universal solution. To extend the service life of the energy chain, especially in abrasive environments, igus has now introduced glide pads with which the chain can be easily upgraded. The wear-optimised sliding elements can be easily placed on the chain links in the inner radius. They are made of a highly abrasion-resistant igumid polymer,” explains igus South Africa MD Ian Hewat.

“Rollers on the new igus energy chains reduce the push/pull forces on long travels and ensure a significantly longer service life of the energy supply system. Their use is particularly worthwhile at high speeds of up to 10 m/s or very long travels where the roller chain links reduce the drive power by up to 37%, saving a significant amount of energy. The new roller chain links and glide pads provide a customised energy supply system for every special application from 50 mm to 1 km travel.”

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation