New sliding material leads to breakthrough in linear technology

Whether an industrial environment or in a coffee machine, in order to maximize the service life of a linear guide and to keep the required drive energy low, it is important to reduce friction and wear as much as possible.

Motion plastics specialist igus says that it has achieved a breakthrough in tribological plastics with its iglidur E3. The German manufacturer has developed a new sliding material that has a friction coefficient that it claims is up to 40% better and able to open up flexibility of design in linear technology.

“Our drylin T miniature linear slide offers extremely smooth running and new design freedom thanks to the newly developed iglidur E3 sliding material. Depending on the operating point, this has a friction coefficient of around 0.16 and thus achieves up to 40% less friction compared to the igus standard materials, measured on hard-anodised aluminium, and even less compared to commercially available sliding materials. This also means that manual adjustment requires 40% lower displacement forces.

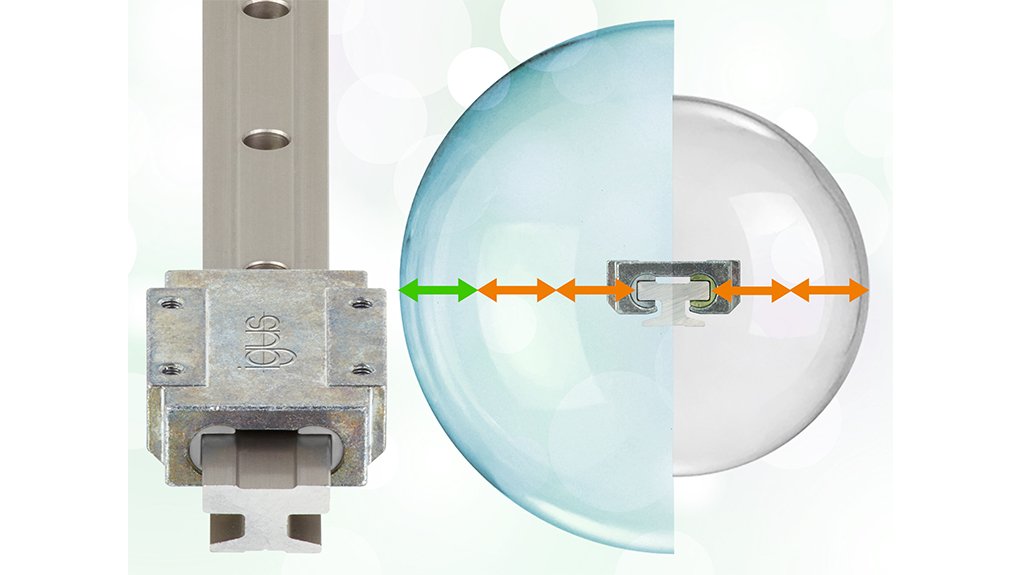

"This is an important step towards greater design freedom, as it enables us to expand design leeway for the first time," says igus head: linear and drive technology business unit Stefan Niermann. The traditional 2:1 rule, which generally applies to linear plain bearings, states that the distance between the driving force and the fixed bearing should not be more than twice the bearing clearance. Otherwise, an uneven movement sequence could jam the system.

“The greater the distance between the drive and the guide bearing, the higher the wear and required drive force. igus has now extended this design rule to 3:1, so that the drive can be 50% further away without impairing linear guide movement. At the same time, the required drive forces are reduced by 40%, which means 40% energy savings in electrically driven applications.

The company’s drylin T miniature guide is available in three sizes – 09, 12 and 15, and can be used in applications such as laboratory and medical technology and tool building. It is said to slide better, without harmful lubricants and the miniature linear carriage with the new iglidur E3 sliders offers the advantages of igus motion plastics. Solid lubricants incorporated into the material of the high-performance plastics aim to ensure low-noise operation, high resistance to dirt and no maintenance.

“Eliminating lubrication is good for saving costs but also the environment. With new material mixing and processing as well as countless tests in the igus test laboratory, igus has further pushed the application limits of motion plastics and created new design freedom in linear technology,” concludes Niermann.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation