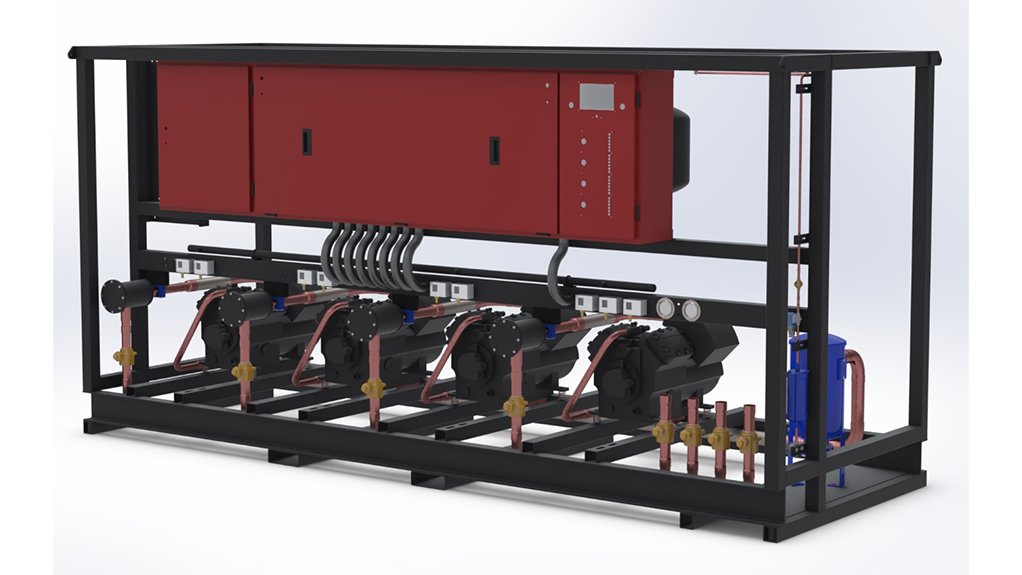

New multiple parallel compressor rack for Freon refrigeration cycles

The development of continuous refrigeration technology has led to the introduction of multiple or parallel refrigeration systems, replacing the previous individual or single compressor systems used for most medium and low temperature applications.

Parallel compressor systems are central refrigeration units utilising three to six parallel commonly piped compressors, single common oil separator, an electrical control panel and a liquid receiver tank mounted on a remote base frame.

The multiple parallel compressor rack, or multiplex, system may be designed for either indoor or outdoor use. The overall selection and design of the multiplex is based on the requirements and limitations related to the specifications of individual commercial refrigeration units. The most important determining factor for the multiplex specification is the correct selection of the system components for the particular application.

Applications in the commercial refrigeration industry are mainly focussed on the cold chain used to refrigerate perishable consumables, produce and products that are required to be stored at different temperature ranges and include supermarkets, abattoirs, the agricultural sector, cold storage facilities and freezer warehouses.

New Metraclark multiplex range

Metraclark states that its engineering department endeavoured to create a standardised modular design that maintains simplicity, reduces manufacturing time and manufacturing complexity, increases ease of installation and maintenance, and increases overall efficiency of the refrigeration system. The design philosophy of the new multiplex frame was to create a complete in-board design of all components fitted to a multiple parallel compressor rack, enabling the building of a single frame for both indoor and outdoor applications with the addition of cladding.

The new semi-hermetic multiplex uses a centralised bent profile member that serves as:

- Mounting point for the suction lines

- Bracket for the pressure switches, gauges, and transducers

- Electrical kopex connection and wire trunking

- Oil return header mount

The centralised main profile shapes the overall frame configuration, and with small alterations, can facilitate both standardised and bespoke multiplex designs, resulting in a range of three to six Copeland semi-hermetic compressors in single and dual suction circuit applications. In addition, the new multiplex incorporates a high oil return efficiency helical oil separator coupled with a low pressure oil management system. The low pressure oil management system makes use of full column gravitational flow from reservoir, through the common 5/8” oil return header, to each individual compressor’s oil level management system.

The electrical enclosure has a full left to right switchgear access philosophy, which allows for the switchgear to be divided into modular individual compressor compartments.

The new Copeland semi-hermetic multiplex is called the Obsidian and represents the company’s flagship of Freon commercial refrigeration products. New short code model reference numbers are used to distinguish between different multiplex units.

The Obsidian Copeland semi-hermetic multiplex was modelled using the computer aided design software SolidWorks, and rendered on SolidWorks Visualise.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation