New mill drive system introduced

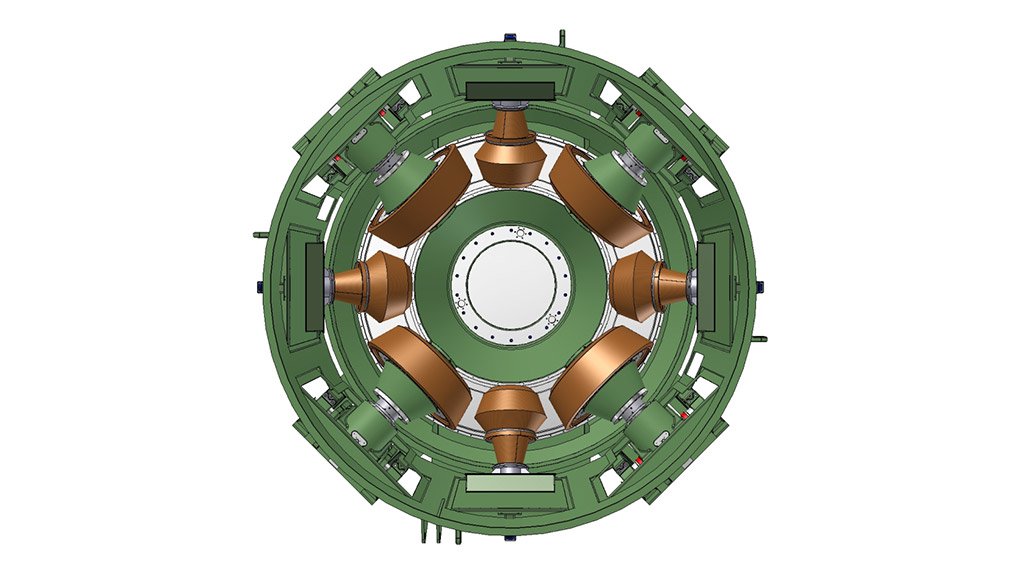

THE COPE GEARBOX The Cope gearbox, which was developed in cooperation with German gear manufacturer Renk, offers up to eight motors at the motor end

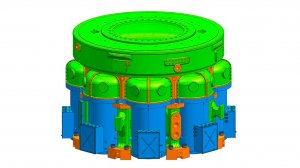

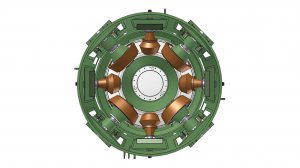

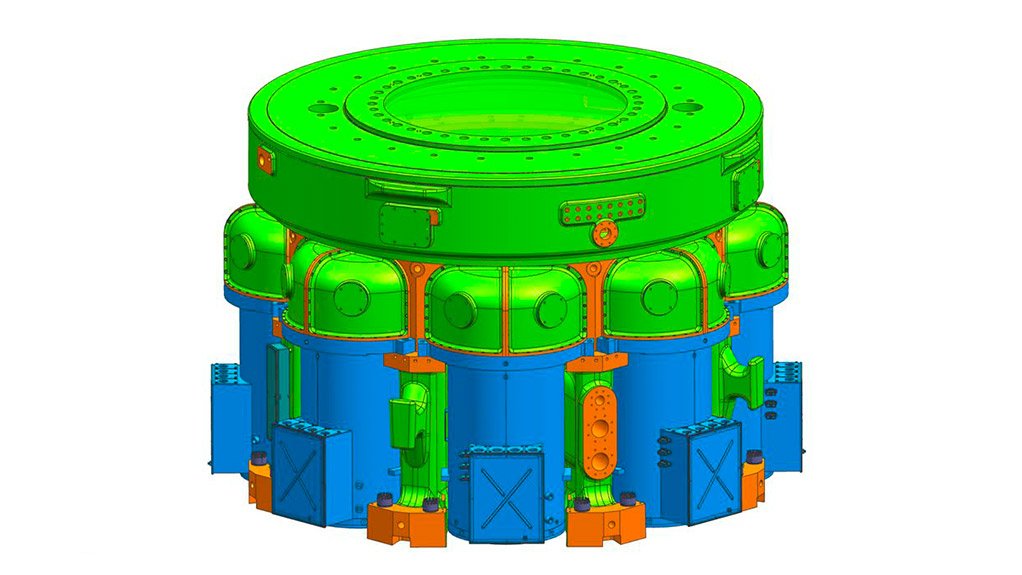

New 4+4 MODULE CONCEPT The 4+4 roller design allows for the mill to be operated with a reduced number of rollers in case of a mechanical failure

Vertical roller mills manufacturer Loesche last year received an order to install a Loesche Mill type LM 70.4+4, in Calabar, Nigeria, the largest Loesche mill to date. Loesche was awarded the contract in July 2014 by Sinoma for United Cement Company of Nigeria (UCCN) – a consortium comprising cement, concrete and aggregates companies Lafarge and Holcim.

Manufacturing of the mill started shortly after the contract was finalised and installation of the equipment will start when it reaches Nigeria in the second quarter of 2015. The grinding plant was completed by the general contractor of the project.

On the UCCN project, Loesche is cooperating with general contractor CBMI Construction, which is a subsidiary of Sinoma, a full-service general contractor in the cement plant construction field. Sinoma is the general contractor for UCCN, while Loesche is a subsupplier to Sinoma.

Loesche tells Engineering News that it has been working on its patented roller technology for more than two decades and that the company has adapted its proven module concept to this greater mill output for the UCCN mill.

Loesche notes that customers in the milling industry can now also use 4+4 rollers, alongside 2+2 and 3+3 rollers.

The company adds that, in the early 1990s, the 2+2 concept was patented, and that this design was later extended to the 3+3 module design.

Highlighting the benefits of the 4+4 roller design, Loesche further explains that the development of the 4+4 roller offers the customer significant flexibility, owing to its ability to increase the capacity of Loesche cement mills.

The company adds that the production output of the Loesche Mill 70.4+4 depends on the cement type, and that the maximum capacity of the mill is about 450 t/h to 500 t/h. The LM70.4+4 is equipped with the LMcommander-mill control system in combination with the LMmaster-mill optimisation module and the LMcomo-condition monitoring system.

“The development of the Loesche Mill 70.4+4 is based on Loesche’s modular design philosophy, which was already used when we transitioned from the 2+2 roller design to 3+3 technology,” says Loesche head cement sales division Stefan Baaken.

He tells Engineering News that the 4+4 roller design allows for the mill to be operated with a reduced number of rollers in case of a mechanical failure.

“There are currently no cement mills of a similar or bigger size in operation globally,” says Baaken. Another advantage of the Loesche Mill LM 70.4+4 is that it can handle the capacity requirements of the project.

Therefore, UCCN benefits because the cost of investing in one large mill system is significantly lower than what the cost would have been if UCCN had bought two separate units.

Particularly, when it comes to larger mill outputs, Loesche favours a drive system with multiple motors, as well as milling force decoupling of the gearbox.

Loesche will use a Cope gearbox for the mill. The Cope gearbox, which was developed in cooperation with German gear manufacturer Renk, offers up to eight motors at the motor end. It operates with or without variable speed drives. The new-drive concept allows for operation with a reduced number of motors, for example, seven, six or only four of the available motors. Even in cooperation with only seven motors, 100% mill output can be attained.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation