New Gauteng Laboratory makes VSD bearing protection affordable in S.A.

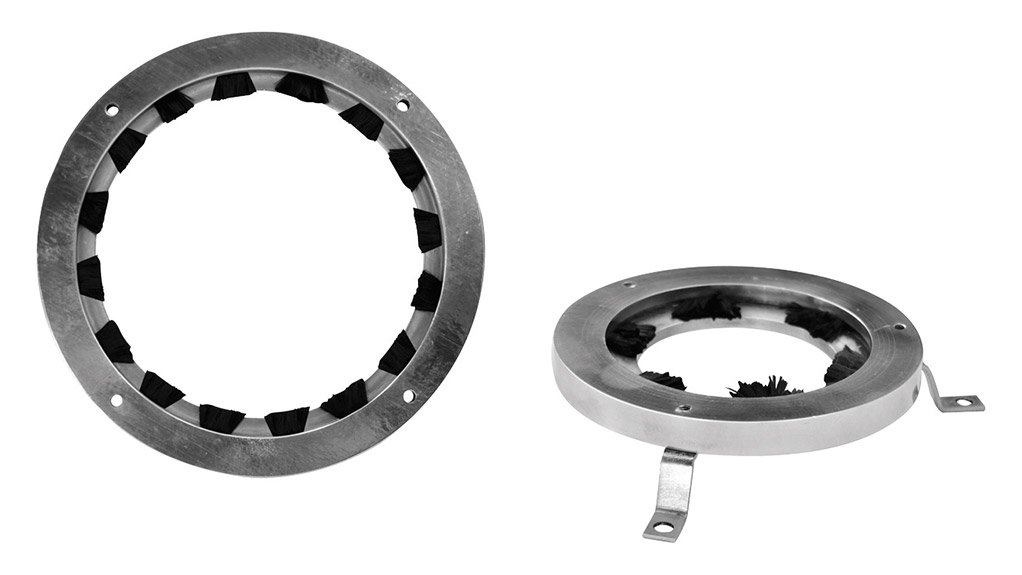

World's First 1 Ring Solution

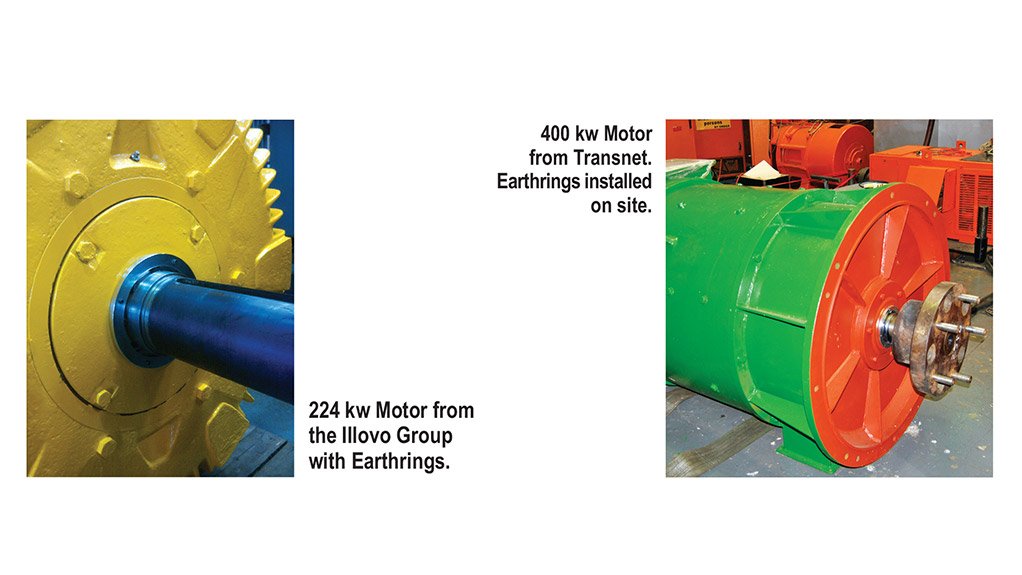

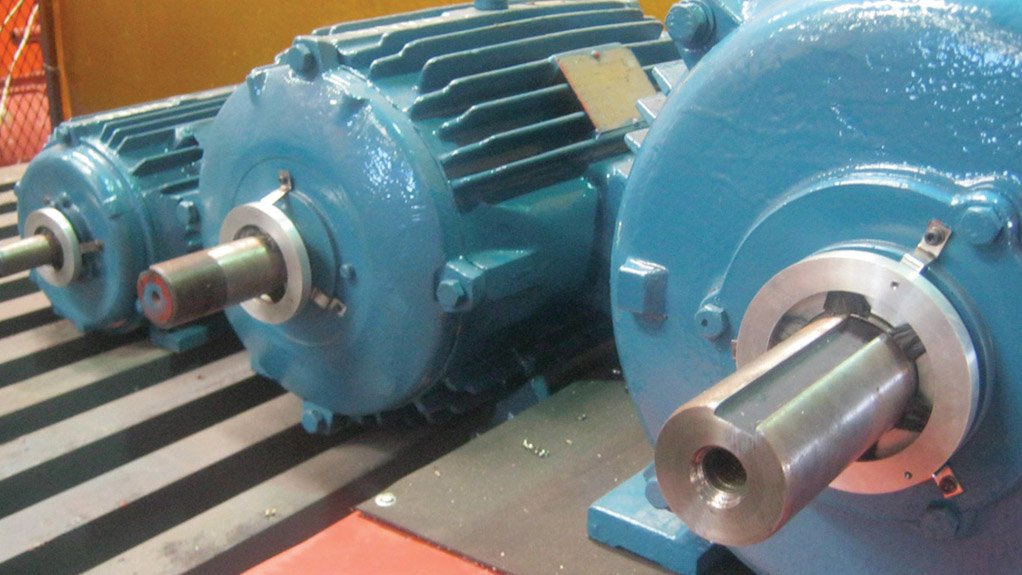

5 years and millions of rands later the new 'Earthrings 350 high current ring' will be launched later this month. Its unique benefit is that only one Earthring will be required to protect AC motors all the way up to 350 kilowatts, no insulated bearings or other products are required.

This saves customers thousands or rands per motor, as well as for the first time making this technology affordable enough to be used on most of the electric motors in a plant, giving South African companies the same maintenance savings and benefits that have so far only been available to their overseas competitors

Motors on VSD's should last 2 x longer

All electric motors on variable speed drives (VSD) should last twice as long as motors originally connected direct on line (DOL), this is a huge cost savings and improvement in plant efficiency, but this is not the case in South Africa.

Most Plants in South Africa don't have protection against VSD (variable speed drive) currents that are damaging their electric motor bearings, even though almost all S.A. motor suppliers recommend protection against these currents if their motors are powered from VSDs'.

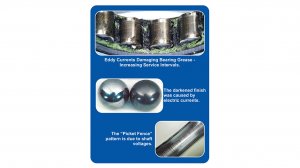

Shaft currents from variable speed drives damage electric motor bearings, reduce grease life, and increase bearing operating temperatures', and add to our operating costs in South Africa, all without most plant Engineers even been aware of how much better their plant could run if this was avoided.

VSD Bearing Protection Rings have been available for years, but have now become a major purchase by Electrical engineers and the maintenance staff all over the world.

New Technology eludes S.A. companies

This New Technology is an Industry standard in most westernized countries, but has eluded S.A. due to the high costs, lack of onsite support and slow supply .

Older less effective technology is still been used in S.A. due to lower costs and lack of understanding of the new technology , costing our plants reduced efficiencies and increased maintenance costs compared to our competitors overseas. Any internet search covering 'shaft currents or Shaft voltages' will make it abundantly clear how serious this problem has become to our plants, especially when our equipment purchase prices and repair costs are increasing as dramatically as they are in South Africa.

Earthrings Pty Ltd is the #No1 selling manufacturer of VSD bearing protection rings in Southern Africa.

Earthrings gears up for exports

Due to the increase in demand Earthrings Pty Ltd, has moved its laboratory to Gauteng to better meet the growing demand for its products, and to start exporting the Earthrings brand to USA, Australia and Europe.

Electric motor leaders' fit rings

As one example, both WEG electric motors and Baldor USA have launched a range of factory fitted motors with the equivalent rings fitted on as standard, once again endorsing and verifying the need for such protection on electric motors powered by VSD's (variable speed drives), to stop electric motor failures and climbing maintenance costs.

Research on a 1000 AC motors on variable speed drives showed that 25% of the motors had bearing faults in the first 18 months on installation and 65% had bearing faults appearing within 24 months of installation. These do not include bearing failures that are declared breakdowns and have started to fail within less than 6 months of installation; Earthrings Pty Ltd has many customer cases and testimonials of these failures in South Africa. Some of which were not correctly identified until bearing analysis was undertaken.

Large S.A. Plant tests motors

A large South African plant tested 13 of their AC electric motors powered by Variable speed drives , of the 13 electric motors tested 10 had high shaft voltages, of these 10 motors 7 electric motors had shaft currents that were classed as extremely High, thereby drastically reducing the life of their electric motors by years.

Undetected failures

Most VSD bearing related failures go undetected by maintenance staff and are normally incorrectly diagnosed as Lubricant failure, human error, inadequate greasing or 'just one of those things' if the failure was detected after 12 or 18 months, and maintenance staff or management not realizing that this motor could have lasted for years longer if it was 'Correctly Equipped'.

Earthrings spends millions in R&D Earthrings Pty Ltd has spent millions of rands in Research and development over the last 5 years and will launch their new improved (2nd generation) range this year called the 'Earthrings 350 high current ring', which will make VSD bearing Protection affordable to all end users in South and Sub Saharan Africa. This development will drastically increase the life of all electric motors on variable speed drives and drive maintenance costs down, while at the same time been very affordable.

Affordable Solutions Critical

The devaluation of the rand has made imported electric motors even more expensive.

Engineers are now lowering costs by purchasing 'Well equipped Electric Motors', not just cheap basic motors.

This so called 'Well Equipped' electric motors are quality electric motors than are designed (or adapted) for the actual customers application, and not a 'One motor fits all solution'.

If customers want to save huge amounts of money they need to purchase new electric motors that are 'Correctly Equipped' for their plants working conditions. This also applies to their Electric motor Service Repair Workshops.

Replaces Insulated bearings

The 'Earthrings 350 high current ring' is also the only bearing protection ring that is used to replace insulated bearings on motors up to 400 kilowatts, but unlike insulated bearings (which has no performance Guarantee in South Africa) the Earthrings 350 high current ring is fully Guaranteed against shaft voltages and currents.

Ex-Explolabs Certified

Insulated bearings may actually increase risks of static build up and are not recommended for flammable enviroments (Ex). Earthrings Pty Ltd has spent millions in R&D to bring South Africa the only VSD Bearing Protection ring for flammable environments (Ex), 'Earthrings Ex', this also protects other attached equipment against static build up, especially in fuel and chemical pipes, thereby increasing safety.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation