New Comos Version 10.2 for faster, more efficient engineering

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

• Predefined interfaces for rapid, secure data exchange

• Innovative functions improve user convenience and reduce workload

• Higher software performance for faster project completion

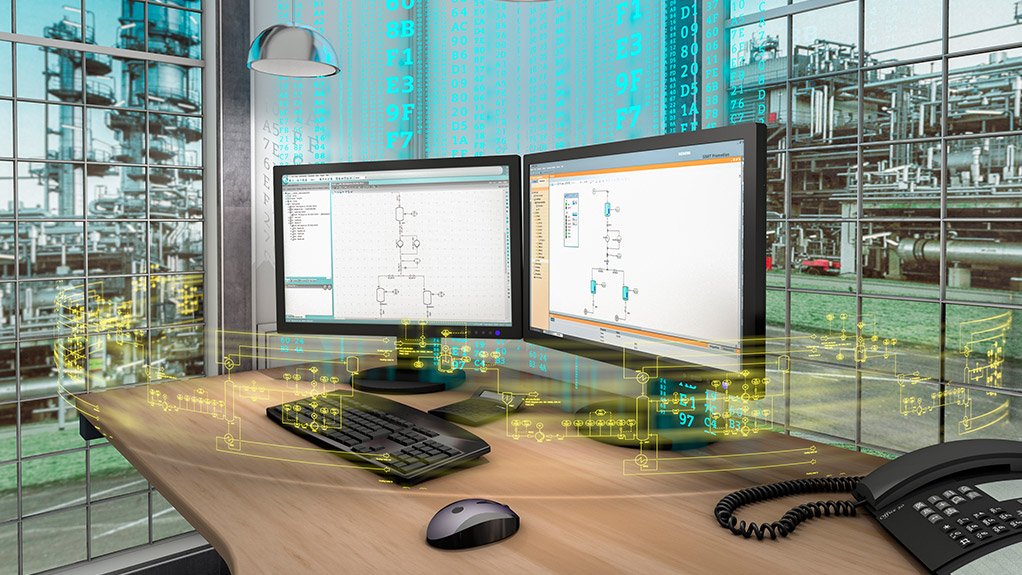

In the latest release version 10.2 of its CAE software solution Comos for the process industry, Siemens has focused on greater interoperability with a number of innovative new features. By enabling the seamless exchange of data between Comos and the simulation platform Simit, Siemens is driving forward its digitalization strategy. A whole host of improvements in the Comos platform make for enhanced software performance, increasing the speed and efficiency of project completion. New developments and extended functions help improve the efficiency of data management across a plant’s entire life cycle, while also enhancing convenience and simplifying decision-making processes for users.

New and improved interfaces for even faster data exchange with external applications underpin the continued expansion of the Comos interoperability strategy. These include the interface to eCl@ss Advanced 9.0 to facilitate the comparison of device data from different suppliers and to allow it to be imported directly into the CAE system Comos, including the relevant documentation. Also improved: interfaces to Proteus 3.6.0, formerly XMpLant scheme, or the Siemens PLM Software Teamcenter. The interface to Bentley OpenPlant announced earlier and developed in cooperation with renowned companies from the chemical industry is now ready for market and enables the capture, exchange, and further utilization of information across the whole life cycle of a plant. In Comos 10.2, it is now possible to generate Bentley “i-models” directly from the piping and instrumentation diagrams (P&ID).

The stored graphic and process data they contain can be used seamlessly in OpenPlant for 3D design purposes, enabling inconsistencies to be avoided and project engineering work to be significantly accelerated. Also new is the interface to the Simit simulation software. Here, a standard interface was developed which allows P&ID information to be transferred directly from Comos into a Simit simulation model. The benefits are faster, more efficient engineering and reduced commissioning times.

Version Comos 10.2 comes with a variety of new functional features and useful wizards designed to make the daily work of users both simpler and more efficient. New symbols in object libraries and additional color coding of objects on P&ID’s make for greater manageability. Electrical engineering has been significantly simplified by the new Marshalling Designer and the Brownfield Loop Wizard. New PERT diagrams make it possible to more clearly visualize maintenance work sequences.

With the 3D virtual reality viewer Comos Walkinside, color coding and the isolation of individual elements, allows project and status checks to be performed directly in the 3D model. This focusing capability means that all those involved in a project are able to more easily gain a uniform understanding of the current status of a plant or project. And the technology provided by the state-of-the-art Oculus Rift virtual reality headset enables realistic training scenarios to be generated.

With the new version Comos 10.2, Siemens is underpinning its digitalization strategy for the process industry. Comos continues to consolidate its position as a high-performance collaboration platform for consistent data management across the whole life cycle of an industrial plant in the process industry.

In the latest release version 10.2 of its CAE software solution Comos for the process industry, Siemens has focused on greater interoperability with a number of innovative new features. By enabling the seamless exchange of data between Comos and the simulation platform Simit, Siemens is driving forward its digitalization strategy.

This press release and a press picture is available at www.siemens.com

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation