Multotec Punts Preventative Maintenance For Longevity Of Trommel Screens

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

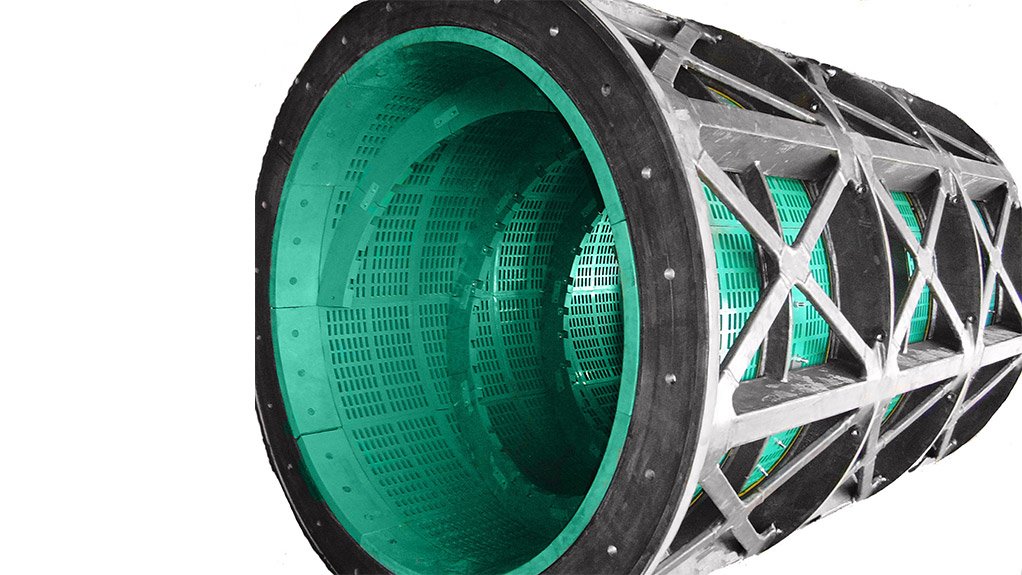

Company Announcement - Preventative maintenance is essential to ensure the longevity of trommel screens. “Multotec has had trommel screens running for over ten years that are still operational,” Anthony Yell, screening product manager, says. Customers can return trommel screens for refurbishment. The rubber lining is stripped off the steel structure, visually inspected for wear and then non-destructive testing carried out to determine the integrity of the trommel structure. “If it is still within specification it can be shot-blasted and re-rubber lined, whereupon it will be good to go for many more years,” Yell explains.

“One of the biggest problems we have today with the larger trommel screens is the high wear rates of the screen media due to the high peripheral speed of the trommel screen itself.” In addition, the trend towards larger mills means higher flow rates and velocities. “Double the velocity on a polyurethane screen equates to an increase in the wear rate by a factor of five,” Yell notes.

“We have invested extensive research and development into producing panels that last longer, as with large copper processing plants where the large tonnages mean an average run time of 12 to 14 weeks without any stoppages for panel change outs. It has been our objective to develop panels that will last that length of time,” Yell says.

Multotec has the added advantage of being able to supply polyurethane panels for smaller feed sizes where the main wear criteria is sliding abrasion and rubber panels where impact is the wear criteria. “We design and manufacture both rubber and polyurethane panels in house,” Yell points out. A recent trend in mineral processing has been that mills are tending to get bigger and therefore trommel screens are becoming larger as well. “This can pose challenges in terms of acceptable life of screen media. However, we do have solutions for this,” Yell says.

“The most important factor for us is understanding the trommel duty and the load coming off the end, because we have to design the front end of the trommel to be able to take this load.” Yell points out. “We have focused investment in developing designs for many years and our trommel screen designs have proven themselves to be exceptionally reliable,” Yell says. “As long as they are maintained properly in terms of the rubber lining and panel replacement, then they will last a long time.”

Multotec is the global leader in trommel screen design and manufacture and has been supplying the market for more than 20 years, Yell asserts. “We deal with most of the major mill manufacturers globally. It is a highly specialised segment that was developed in South Africa and Multotec has built a reputation that now enables us to supply internationally.”

Multotec has manufacturing plants in South Africa and Chile and can also supply spare parts from South Africa, Australia, Chile and the US, which reduces the supply chain dramatically and extends its geographic footprint. “We have supplied mill and scrubber trommel screens to the four corners of the earth, from South America to Papua New Guinea and Siberia to Kazakhstan. There are not many places where they are not prevalent as the Multotec product has proved to be highly reliable.”

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation