Modern Concrete Roads Now Offer Ride Comfort And Safety

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

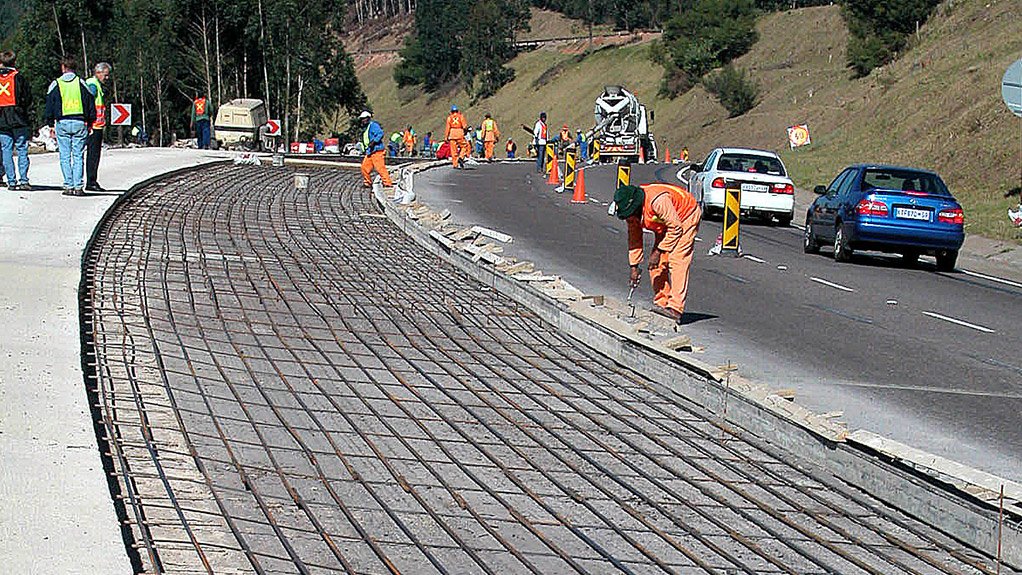

Concrete roads suffer from an image problem because many very old concrete pavements still in existence were designed long ago to very different design criteria than modern concrete pavements, says Bryan Perrie, MD of The Concrete Institute.

Perrie says decades ago concrete roads were constructed using what are now regarded as obsolete equipment and techniques that negatively affected ride comfort. “Although safety has always been a major concern, ride and acoustic comfort were barely considered 40 years ago. Modernised designs, new construction methods, better surface finishing and high-technology machines mean that it is nowadays perfectly possible to realise high quality concrete pavement surfaces that do indeed satisfy the needs and objectives of road users, communities who live near the pavements, as well as road managers.”

Surface evenness, characterised by longitudinal evenness and mega-texture as well as rut formation, has a significant impact on the ride comfort of vehicle passengers. “Early concrete pavements were perceived as being uncomfortable to ride on because of the widths of the joints and faulting at the joints due to a lack or loss of load transfer, or because of localised damage to supporting layers that contained material susceptible to erosion. However, since the early 1970s, this problem has been dealt with by modified concrete pavement design.”

Perrie says these solutions included:

Shorter slabs of concrete (minimum 4m long) that make the pavement less prone to cracking;

Narrow contraction joints that limit the joint nuisance to a minimum; and

Dowels in the transverse joints and cement-bound bases that ensure excellent load transfer and no longer allow any level differences at the joints.

“Continuously reinforced concrete is often chosen for motorways and primary roads as this form of construction does not feature transverse joints. The shrinkage of the concrete is absorbed by a pattern of narrow, closely spaced cracks that have no impact whatsoever on the pavement’s evenness or ride comfort.”

Smooth concrete roads can now be built thanks to:

Optimised concrete mixes with constant workability, prepared in modern computer controlled mixing plants that are often set up on the site itself;

New generations of slipform pavers equipped with automatic vibrator control systems;

Properly installed guide wires for controlling the machine or wireless systems that make use of total stations;

The use of longitudinal levelling beams behind the finishing machine (“super-smoothers”); and

New types of evenness measurement set up immediately behind the paver, thus allowing the correction of the construction process.

“Apart from countries where studded tyres are allowed, concrete pavements are immune to rut formation. An important property of concrete pavements is that the longitudinal and transverse evenness obtained after construction is retained for many years,” Perrie adds.

When it comes to safety threats - such as skidding, aquaplaning and visibility - accidents can be prevented in both dry and wet weather by providing a good surface texture with sufficient surface friction. Concrete pavements’ capacity to counter skidding have been improved in recent years through fine exposed aggregate surfaces that show no significant decrease in skid resistance over time.

“The texture of the pavement, combined with the transverse profile, has a major influence on the potential danger of aquaplaning which happens when the tyres of the vehicle lose all contact with the pavement surface. As concrete surfaces do not form ruts, the likelihood of this is virtually non-existent if the transverse profile is given the correct super-elevation.

Transverse textures or exposed aggregate surfaces with sufficient texture depth will also substantially limit splash and spray coming from behind vehicles. The colour and texture of concrete pavements can also be varied to warn motorists of impending hazardous situations.”

Concrete pavements’ traffic noise can be controlled through various means that include:

The use of barrier walls that are particularly effective on pavements with heavy truck traffic;

Building the roads an adequate distance away from people living in the vicinity; and

Controlling the noise at source- at the pavement surface. “In recent years, numerous noise-abating wearing courses have been developed and research and testing are still ongoing in many countries,” Perrie adds.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation