Mining automation forging ahead

The goal of autonomous mining is to create a safer and healthier environment for workers by removing them from potential high risk areas while also making mines more productive by increasing output in available operating time.

To this end, De Beers has devised an autonomous mining roadmap for its Venetia Underground Mine (VUG) that it says will result in the new $2-billion mine becoming one of the most mechanised and automated mining operations in the world.

The company explains that its VUG replaces openpit operations at the Venetia diamond mine and will extend mine life to at least 2046. Expected to start production within 2023, it will use the sub-level cave mining method.

According to De Beers automation and information principal Giel Marais, the objective of automation at the VUG is to have a number of autonomous mining systems performing multiple mining processes by 2027.

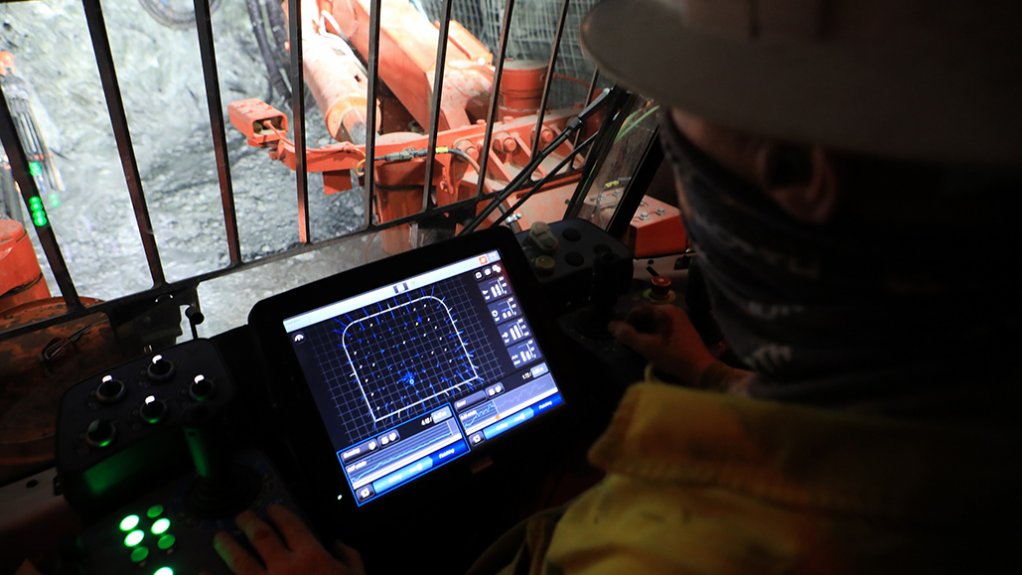

“In the case of the VUG, our primary technology partner is Sandvik Mining and Rock Solutions, which manufactures a full range of ‘intelligent’ mining machines that can operate independently underground within access controlled safety zones or be remotely operated from control rooms on surface,” he says.

The implementation of automation at the VUG will be phased in incrementally, starting with automated machines which still require an onboard operator but include many automated functions, followed by the introduction of autonomous machines which do not require an onboard operator and are equipped with automated machine navigation and tramming and can perform most routine functions without operator input, while stationary in one location. The final phase of implementation will see the introduction of full autonomous mining systems.

The key characteristic of autonomous mining systems is the use of multiple autonomous machines which are managed by an integrated central traffic management system. The machines operate in predefined safety zones that are dynamically combined to create autonomous operating areas.

Sandvik Mining and Rock Solutions is supplying all the primary mining equipment for the VUG for both mine development and production, including machines for development and production drilling, rock reinforcement, and loading and hauling. Sandvik is also providing its AutoMine system for the remote operation of loaders and trucks and its OptiMine system for machine health monitoring, task management and location tracking.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation