Miner implements measures to boost production

IMPROVED PRODUCTION DESPITE SETBACKS Delivery of outstanding equipment at Cullinan and Finsch, as well as hiring people in senior technical roles at Finsch, has helped improve production

OPTIMISING RESOURCE POTENTIAL Cullinan has a potential mine life that could take mining beyond 2040, while Finsch has a mine life beyond 2035

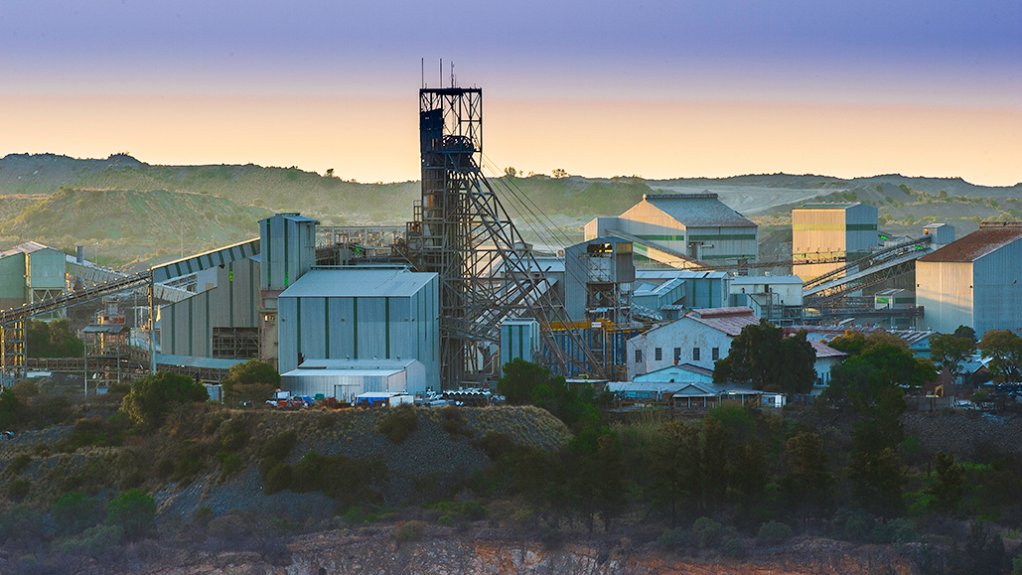

Diamond miner Petra Diamonds improved its diamond mining performance in the third quarter of its 2023 financial year, ended March 31, in the wake of lower production in the quarter prior.

This improvement was effected despite halted operations at the company’s Koffiefontein and Williamson mines, in South Africa and Tanzania respectively, states Petra Diamonds CEO Richard Duffy.

“We’ve received delivery of outstanding equipment. This includes our load, haul and dump machines and drill rigs, particularly for the Finsch mine. We also had equipment delivered at Cullinan mine.”

Although equipment is still being delivered and commissioned, Duffy says “we’re already seeing the benefits, with fewer breakdowns and higher productivity”.

Petra Diamonds has also employed more people in senior technical roles, particularly at Finsch.

These factors have resulted in an improved and more stable operation performance.

“Cullinan mine has been performing well, but we’ve had challenges with low-grade ore, and we’ve implemented steps to mitigate that. Our immediate focus is to ensure that we operate consistently, and focus on improving our business, which is entrenched in our operating model. This will hopefully ensure we produce more predictably over the long term,” he states.

Restarting Williamson

In November 2022, the eastern wall of the tailings storage facility (TSF) at Petra Diamonds’ Williamson mine was breached, resulting in flooding away from the pit, extending into areas outside the mine-lease area.

Duffy confirms that after the TSF failure, one-third of the material escaped, and that Petra has closed the breach and ensured that it is secure.

The company has also constructed berms downstream of the wall to ensure that, going forward, any outgoing material is contained. This work was completed at the start of this year.

The main portion of the tailings were contained by the New Alamasi water dam, located within the mine lease area.

“Because the Alamasi water dam was inundated with tailings material, we undertook to construct a new freshwater dam,” he says.

Although the dam was on the mine lease area at Williamson, it was used by the community as a freshwater resource and to sustain livestock.

Duffy confirms that the new freshwater dam has been completed and it is about 75% full, securing water supply to sustain communities and livestock in the area.

“The failure mechanism was subsidence in the tailings wall. We haven’t established the root cause of this, as this requires specialist forensic drilling to establish what might have happened. We’re doing this and have secured a contractor and a rig.”

The results are expected later this year, after which the miner will provide more information on what triggered the failure mechanism, and assimilate any insights from the findings into other operations.

Petra is also constructing a new TSF for Williamson, and will not use the old TSF until the results of the forensic drilling are completed and the results permit its reuse.

“We’re revisiting our other TSFs and implementing the Global Industry Standards On Tailings Management. We have substantial monitoring on all of our TSFs, and will ensure the new TSF for Williamson has the same level of monitoring,” says Duffy.

Duffy also stresses that Petra is targeting having these standards fully implemented later this year.

Mitigating Suspended Production

Petra has also suspended production at its Koffiefontein mine, in the Free State province of South Africa; the mine has been placed under care and maintenance, as it has been incurring losses.

“We have agreed and implemented a retrenchment process with organised labour. We have a significantly reduced team carrying out the care and maintenance, and we’re focusing on a responsible process to mine closure. This will consider all key environmental, social and community obligations,” says Duffy.

While Petra has lost over six months of production, it navigated this period using its sufficient cash resources, which were supported by the revenue from a 32 ct pink diamond that was discovered at Williamson before the TSF failure.

“We’ve taken advantage of this period to do planned maintenance in the plant for Williamson, and profiling and stripping in the openpit. We’ve done much to ensure that the mine is ready to ramp up as quickly as possible once the new TSF is in place,” he adds.

Petra is focusing on its existing operations at its South African mines to ensure that it enhances its resources.

Cullinan has a potential mine life that could take mining beyond 2040, while Finsch has a mine life beyond 2035.

Meanwhile, Williamson has a mine plan to 2030, but Duffy highlights that Petra has yet to extend and renew the mining licence, as the orebody could be mined beyond 2040.

“We need to optimally exploit these resources to ensure that we can continue to mine sustainably. We have further growth opportunities and studies we need to carry out to continue mining in the long term.

“We’re focusing on stable operations, completing existing projects on time and to budget, and completing studies to extend mine lives at Cullinan, Finsch and Williamson,” Duffy concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation