Mike Eksteen reflects on twenty-fifth anniversary of Kloof Gold accident

Dirk Albrecht & Mike Eksteen

Photo by Nadine James

Kloof Shaft 3 October 13, 1993

Photo by Dirk Albrecht

Kloof control room October 13, 1993

Photo by Dirk Albrecht

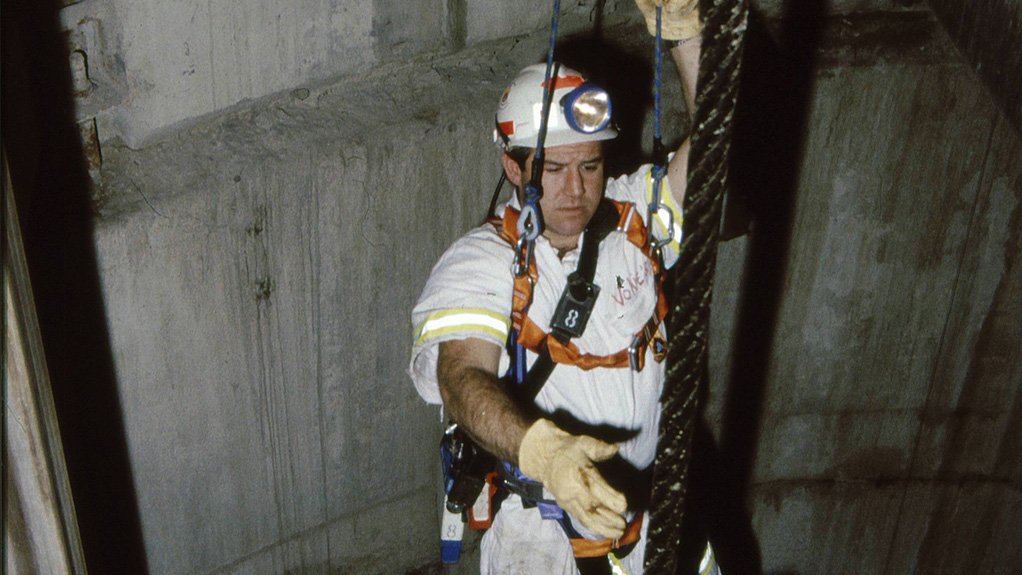

Vaal reef proto team member

Photo by Dirk Albrecht

Medical stop

Photo by Dirk Albrecht

October 19 marked the twenty-fifth anniversary of the successful rescue of 150 miners trapped 3 km underground at the Kloof Gold Mine No. 3 sub shaft, in Westonaria, west of Johannesburg.

Former Kloof Gold Mine GM Mike Eksteen, who helmed one of the most successful mine rescue operations in South African mining history, offers some insight into the near week-long rescue operation, which concluded without fatality.

“There were 3 000 miners below ground during that October 13 shift. You cannot imagine the amount of stress and responsibility that settles on your shoulders when you get a message that a shaft has been wiped out . . . and then, that at least 150 people have been trapped, with no way of getting out.”

The mine had been commissioning a hydropower column when a failure occurred. Twenty-six tons of hydropower piping dislodged from its bracket, fell down the shaft stripping the shaft steelwork, gathering debris as it fell, destroying all hoisting capability and communications from 27 level downwards.

Mineworkers on Level 35 and above could use alternative means of egress. Those on levels 37 and 39 were directed to Level 35 once communications were restored. There, an escape ladder could be used to ascend to Level 31, where mineworkers could use the connecting haulage to the No.1 sub shaft to be hoisted to surface.

Those on levels 41 and 43 and on the shaft bottom service level were trapped.

All personnel cages, conveyances, counterweights and skips were inoperable, owing to the debris totally blocking the shaft.

Eksteen recalls setting up a control room, sending out a reconnaissance team, contacting the locally based Mine Rescue Services teams (proto teams), contacting the company’s executive management, and preparing for the inevitable media briefing.

The accident had occurred at about midday. By evening power and communications had been restored down to Level 35. Kloof’s own proto teams then established radio communication from levels 35 to 39, transmitting signals down the damaged shaft.

A borehole rescue winch arrived in the early hours of October 14. It was modified and mounted on Level 35 to allow for access through the broken steelwork. The proto teams also set up a Rollgliss on Level 39, enabling a member of the Vaal Reef proto team to descend 280 m down to Level 41. “It took 18 hrs for the first proto guy to get to Level 41,” says Eksteen.

He recalls that the media had congregated in the control room when first contact with Level 41 was established. “During the early part of my presentation to the media my phone rang, which annoyed me.” He remembers scolding his PA for interrupting but she replied “Mr Eksteen, this is a call you want to take.”

He put the phone on speaker, and the message from the Vaal Reef abseiler was: “All accounted for and in good health”.

“Once the media heard that, they left . . . they didn’t have enough manners to stay to hear my presentation,” Eksteen notes wryly. He adds that the media did not return, not even when the last mineworker was rescued.

Despite the seeming lack of interest, the rescue was extremely complicated.

Proto teams on 39 level used the Rollgliss to raise miners from 41 level to 39 level.

Eksteen explains that initially, workers would shout out commands on the radio while being lifted, manoeuvring through the debris by rearranging the rope or his body position to avoid the twisted steel work and loose debris.

Another Rollgliss was used to descend from levels 41 to 43. By 20:30 on October 14, the Kinross proto team, which included paramedics, made their way to Level 43. Aside from ascertaining whether the workers were medically safe, they also found an escape route away from the loose steelwork by clearing rock from the lined orepass.

In the early hours of October 15, the first men were hoisted up to Level 41.

Eksteen notes that Kloof engineering manager Fred Brear suggested the use of Bosun’s chairs lifted by electrical rope motors – Skyjacks – and powered by portable diesel generators to accelerate the process. It was the first time that anyone thought to use skyjack motors for a mine rescue operation, he adds.

The chairs were made in the mine’s workshop. All of the equipment – the four skyjacks, the bosun’s chairs, generators and ropes – were carried down to Level 39. Additionally, the proto teams and other volunteers had been carrying food, medical supplies and fresh water down throughout the rescue.

The proto teams set up medical and rest stops along the egress route. “Workers would be hoisted up, checked by the medical staff, they would sleep underground for a few hours before travelling 9 km up to the surface,” says Eksteen.

He stresses that emphasis was placed on ensuring that workers were fit enough to tackle the escape route, rather than getting the workers out quickly, potentially jeopardising their health and safety.

Six days after the accident, at midday, the five remaining miners and supervisors arrived safely on surface.

Eksteen describes the rescue as a culmination of the industry’s preparedness, and the proto teams’ bravery.

TIPS FROM EKSTEEN

“People outside of the industry don’t understand the extent to which proto teams would risk their own lives for those of their fellow miners. Furthermore, the public does not understand the strain that management is under during the entire rescue operation... when all is over then the exhaustion hits you like a brick wall.”

He asks that mine managers note three things from his experience. “Firstly, when the accident happens you’re on your own. None of the executive management want’s to be associated with a tragedy . . . they’ll be there once everything is over, if the rescue is a success.”

Secondly, managers should be aware of, and address, misinformation spread by the media. “Journalists interview workers, or people from the community . . . people with little or no insight into how or why the accident occurred. Arrange a media conference so that the correct information is being relayed.”

Finally, “you need to have an excellent team supporting you.”

He recalls supervisor Dirk Knaap speaking to the media a week after the rescue telling the reporter that he never feared for his life because he knew “Mike sal ons kom haal” (Mike will get us).

He stresses that a mine management team needs to be worthy of that kind of trust, by being innovative, knowledgeable and committed to the wellbeing of the staff.

“We had built such a formidable management team. All of us were willing to take on the responsibility and that made a big difference.”

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation