Metrorail refurb to run for 15 years, CTLE rail theft being resolved

A Metrorail coach in need of refurbishment

Photo by Duane Daws

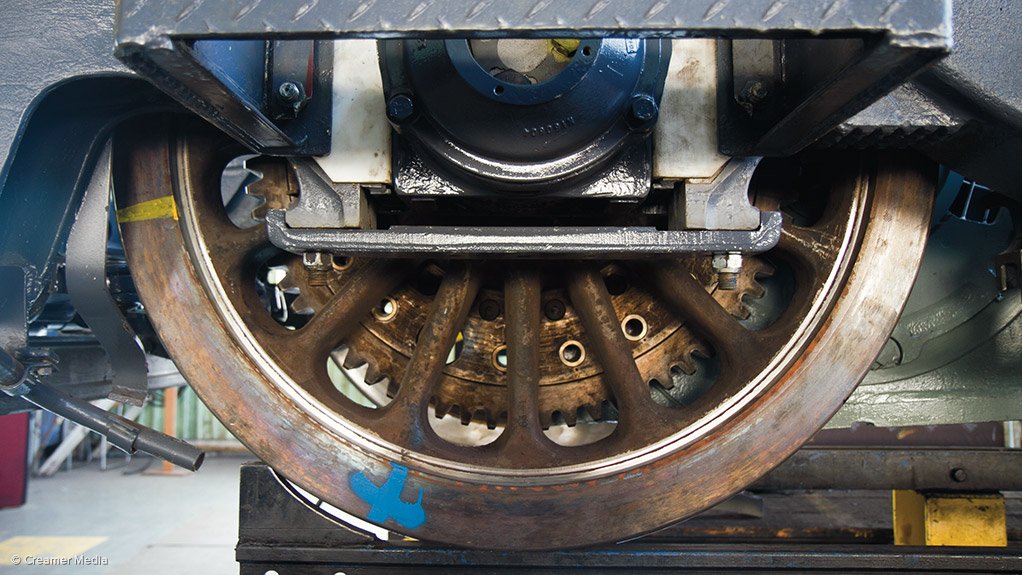

The coach is stripped and refurbished from the bottom up

Photo by Duane Daws

The coach is stripped and refurbished from the bottom up

Photo by Duane Daws

The coach is stripped and refurbished from the bottom up

Photo by Duane Daws

The coach is stripped and refurbished from the bottom up

Photo by Duane Daws

The finished product, ready for delivery

Photo by Duane Daws

The finished product, ready for delivery

Photo by Duane Daws

The finished product, ready for delivery

Photo by Duane Daws

PRASA long-haul locos being refurbished at CTLE

Photo by Duane Daws

Inside CTLE's Nigel facility

Photo by Duane Daws

The Passenger Rail Agency of South Africa (PRASA) will continue refurbishing its existing Metrorail fleet for another 15 years, despite the R51-billion acquisition of 600 new trains of six cars each, signed last year.

Not all the new coaches will come on stream at once, which means the existing fleet has to continue working for quite some time, says Commuter Transport & Locomotives Engineering (CTLE) operations executive Craig Holden.

The 100% black-owned CTLE will refurbish 100 Metrorail coaches for PRASA this financial year, at its facility in Nigel, as part of the State entity’s general overhaul programme.

CTLE acquired the Union Carriage & Wagon assets from the Murray & Roberts group in 2013.

PRASA is currently refurbishing around 500 coaches a year.

The passenger rail agency has spent R2.1-billion on the refurbishment of 570 coaches since 2010, says PRASA marketing and communications senior manager Nana Zenani.

“The engineering division within PRASA determines which coaches are sent for refurbishment.”

The CTLE facility has 68 000 m2 under roof and employs 750 people. There is also a welding school on site.

In order to speed up work on the 35- to 50-year old Metrorail coaches, PRASA has changed its refurbishment methodology.

Repairs used to be done to a general specification on each coach, but this was “too expensive and it took too long”, explains Holden.

Refurbishment is now condition-based, where each coach is individually assessed and repaired.

“This means we can work much faster,” says Holden.

It takes, on average, 49 days to overhaul a motor coach, and 40 days to refurbish a trailer coach.

Local content on the overhaul is around 85%.

The biggest problem in tackling the old coaches is that they have been overhauled three or four times before, says Holden.

To illustrate this, he refers to the action of a screw being inserted into wood three of four times, at the same point.

“At some stage, there is nothing left to work with.”

Rewiring is the biggest work when refurbishing the coaches, by volume, with the most expensive parts of the job including having the wheels reprofiled, refurbishing the bogies, and fitting the doors with new controllers.

RECAPITALISATION AMBITIONS

CTLE hopes to participate in the R51-billion PRASA recapitalisation programme, says Holden, as there is “enough work for everyone in the industry”.

The company has just completed two locomotive refurbishment contracts for freight hauler Transnet.

CTLE overhauled 110 19Es and 76 15Es for the coal and iron-ore lines.

CTLE is also busy overhauling locomotives for PRASA’s long-distance rail service, and will complete 20 6E units in what is a new contract for the company.

“We hope to produce new bogies soon too,” says Holden. “That will move us up the value chain.”

STOLEN RAILWAY LINE BEING REPLACED

Around 5 km of rail have been stolen, on local council land, between the CTLE facility and the larger Gauteng rail network.

This means that it is currently impossible to deliver 33 Metrorail coaches, which have already been overhauled, to PRASA. They are left stranded in CTLE’s rail yard.

PRASA can also not deliver new rolling stock in need of refurbishment to CTLE.

Holden says Transnet is “on site”, busy repairing the railway line to the company’s Nigel facility.

“The rate at which the line disappeared is quite alarming.”

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation