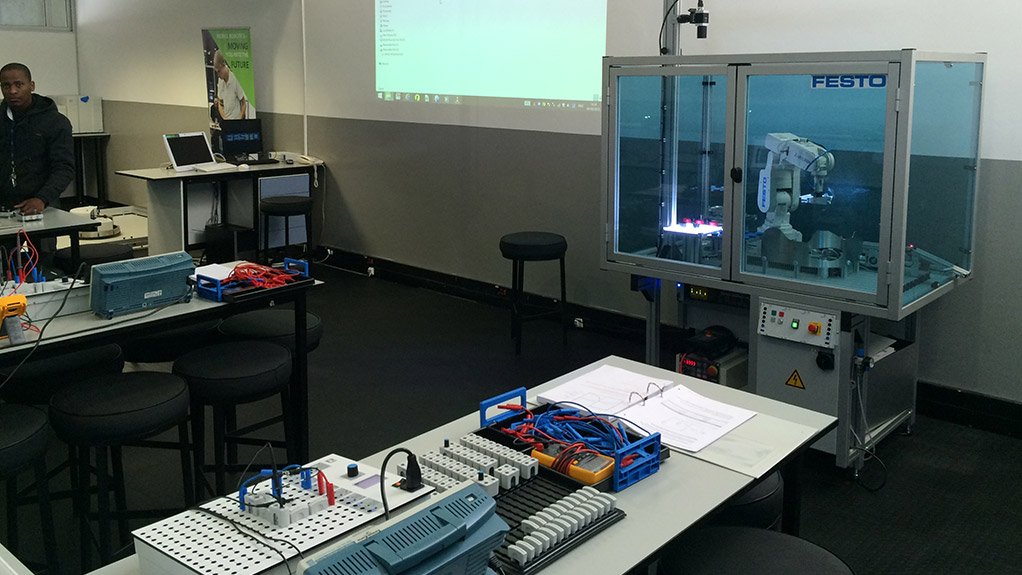

Mechatronics laboratory enables pupils to explore industrial systems

MECHATRONIC MANUFACTURING Pupils can explore and trial picking, sorting and handling systems, as well as the integration of these subsystems to create a manufacturing circuit

ELECTRICAL CIRCUITS Pupils using the laboratory can set up and trial electrical circuit to safely explore industrial circuitry

SIX-AXIS ROBOTIC ARM The six-axis robotic arm demonstrates some of the most advanced technologies in manufacturing to pupils

The Mechatronics laboratory, or MecLab, at science centre Sci-Bono, in Newtown, Johannesburg, will enable school pupils to build, test and operate industrial handling and automation systems, says Sci-Bono CEO David Kramer.

“A key problem that educators and industries face worldwide is that education always lags developments in industry. “This new laboratory, which houses industrial systems donated by [industrial automation multinational] Festo, will enable schoolgoing children to work with state-of-the-art industrial systems, and design, explore, test and operate them.”

Kramer hopes that students who are exposed to these industrial systems might even be ahead of where the companies expect them to be, once they have completed their tertiary education and entered employment, owing to their exposure to such systems at Sci-Bono.

The lab is not only about educating pupils in technology, but also about igniting interest among pupils to choose technical and scientific fields of study, he notes.

Kramer believes that technical skills are a requirement for economic development and that it would be a “strategic failure on the part of government and society” if the country fails to develop sufficiently skilled young people in these fields.

“We have a window of opportunity to create thousands of technically trained youths, and we are helping to keep this window open through the use of this lab. “The Gauteng Department of Education and Sci-Bono aim to increase the flow of young people into mechatronics,” he emphasises.

The MecLab is on the fourth floor of the Sci-Bono Education Centre and has a variety of different industrial systems – mechatronic manufacturing modules with picking, sorting and handling systems, electrical circuit testing systems, pneumatics actuator systems, ‘bionics’ for engineering from nature, mobile robotics, a three-dimensional printer and a fully functional industrial six-axis robotic arm with welding and vision.

Each of the teaching systems has a monitor for elearning, which provides detailed information on all the components and processes of that system. The monitors are also used to control the systems once pupils have set up and programmed the specific circuit or processes they are trialling or exploring.

Sci-Bono laboratory manager Michael Ellis notes that children exploring systems inter- actively, and learning by doing, are the best ways to get them interested in science and engineering subjects.

One member of the Tshwane North tehcnial and vocational education and training college and BMW team that won the South African section of the WorldSkills mechatronics competition, Tressure Mokgohloa, demonstrated the different industrial systems and how pupils use them during National Science Week, in July. He will fly out to Brazil to represent South Africa in the mechatronics division of the World Skills International competition during this month.

Festo Southern Africa didactic manager Horst Weinert notes that the company is excited about the opportunities and prospects of developing skills among youths through its partnership with Sci-Bono.

“Festo has a significant skills development component, representing about 10% of our turnover a year. “We are known as a learning-orientated company with the motto‘Teach first, sell later’, which reflects our aim of developing skills in the countries we operate in and the companies we serve, which also then enables them to buy and use our systems to improve their operations,” he concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation